مورد محور العجلة المخصص للتصنيع باستخدام الحاسب الآلي

تم تصنيعها بدقة باستخدام التشكيل والطحن باستخدام الحاسب الآلي للسيارات الصغيرة والدراجات النارية والدراجات الكهربائية — موثوق بها من قبل الشركات المصنعة والبائعين والفرق في جميع أنحاء العالم.

• الألومنيوم المستخدم في صناعة الطائرات

• 100% قابلة للتخصيص حسب مواصفاتك

• الشحن العالمي والدعم من الخبراء

مزايانا الرئيسية

من تشكيل القضبان إلى محور العجلة النهائي، نتعامل مع كل خطوة باستخدام آلة CNC متعددة المحاور المتقدمة.

الأداء القابل للتحقيق

تم تصميم محاور العجلات لدينا بدقة لتتحمل الاستخدام في العالم الحقيقي وبسعر تنافسي.

نحن نقدم مجموعة واسعة من الخيارات لتتناسب مع مواصفاتك، بما في ذلك التصميم والمواد والأبعاد، وما إلى ذلك.

خيارات التخصيص

| مادة | تتضمن الاختيارات الشائعة الألومنيوم 6061-T6 و7075-T6؛ والمواد الأخرى قابلة للتفاوض. |

| أبعاد | القطر، العرض، حجم التجويف، ارتفاع الشفة، كلها قابلة للتخصيص بالكامل |

| نمط الترباس | PCD، عدد الثقوب، حجم الخيط، وقطر المركز، متوفرة في الإصدارات القياسية أو المواصفات المخصصة. |

| ملاءمة المحمل | مقاعد محمل دقيقة (تركيب بالضغط أو تركيب بالانزلاق)، وفقًا لمواصفاتك |

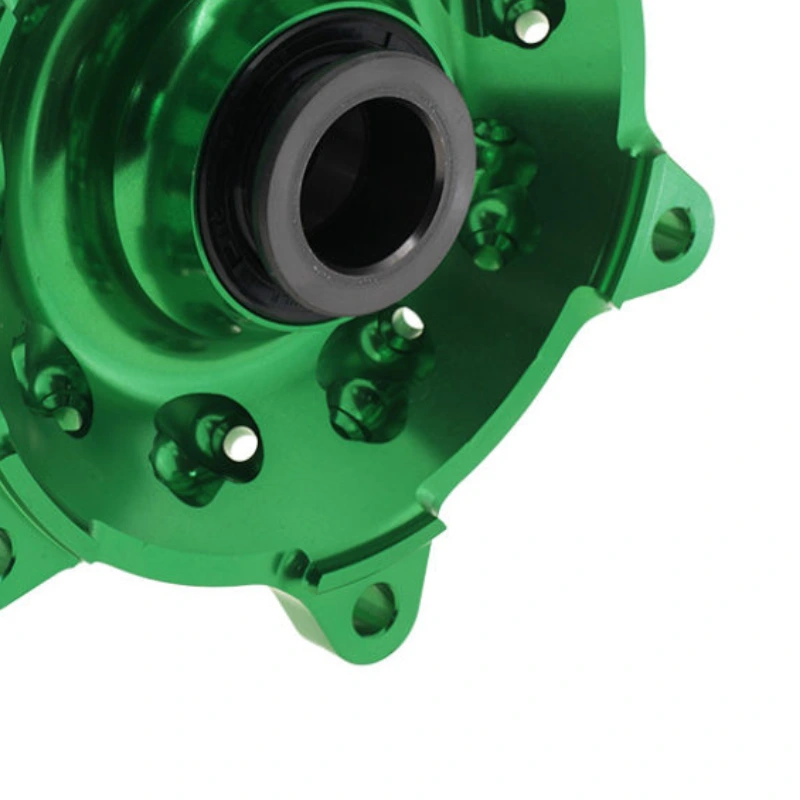

| ينهي | الأكسدة (الشفافة، السوداء، الخ)، النفخ الرملي، التلميع، الخ. |

| الشعار / العلامة التجارية | نقش الشعار أو الأرقام التسلسلية أو رموز الدفعة بالليزر |

محور العجلة حسب التطبيق

تختلف احتياجات المركبات المختلفة. إليك أنواع المركبات التي نخدمها عادةً.

دراجة نارية

نقوم بتخصيص محاور العجلات لجميع ماركات الدراجات النارية، KTM، هوندا، وما إلى ذلك. قوية وموثوقة وجاهزة للطريق.

دراجة بي إم إكس

محاور قوية قادرة على تحمل الضربات القوية - سواء كنت في حديقة التزلج أو على المسار.

دراجة إلكترونية

تم تصميمها للتعامل مع عزم الدوران الإضافي من المحركات الكهربائية، مع الحفاظ على الأمور سلسة وهادئة.

محور العجلة حسب المادة

تؤثر المواد على الأداء والتكلفة. إليك الخيارات الأكثر شيوعًا.

6061-T6 الألومنيوم

خيار متين وبأسعار معقولة. يتميز بمتانة عالية، وسهل التشغيل، ويعمل بكفاءة في معظم الاستخدامات.

7075-T6 الألومنيوم

أقوى وأكثر صلابة. مثالي إذا كنت بحاجة إلى متانة إضافية أو وزن أخف للسباقات أو الأحمال الثقيلة.

الفولاذ الكربوني

قوة ومتانة عالية بتكلفة مواد منخفضة. مناسب للمشاريع الصعبة أو ذات التكلفة المنخفضة.

محور العجلة من Finish

اللمسة النهائية المناسبة للسطح تُحسّن المظهر والحماية. اختر ما يُناسب ذوقك.

مؤكسد

نظيف، ملون، ومقاوم للتآكل. متوفر بألوان الأسود، الأحمر، الفضي، أو بألوان مخصصة. يتوفر النوعان الثاني والثالث.

مطلي بالكروم

لامع وكلاسيكي. مثالي لمن يحبون الفخامة.

خام آلي

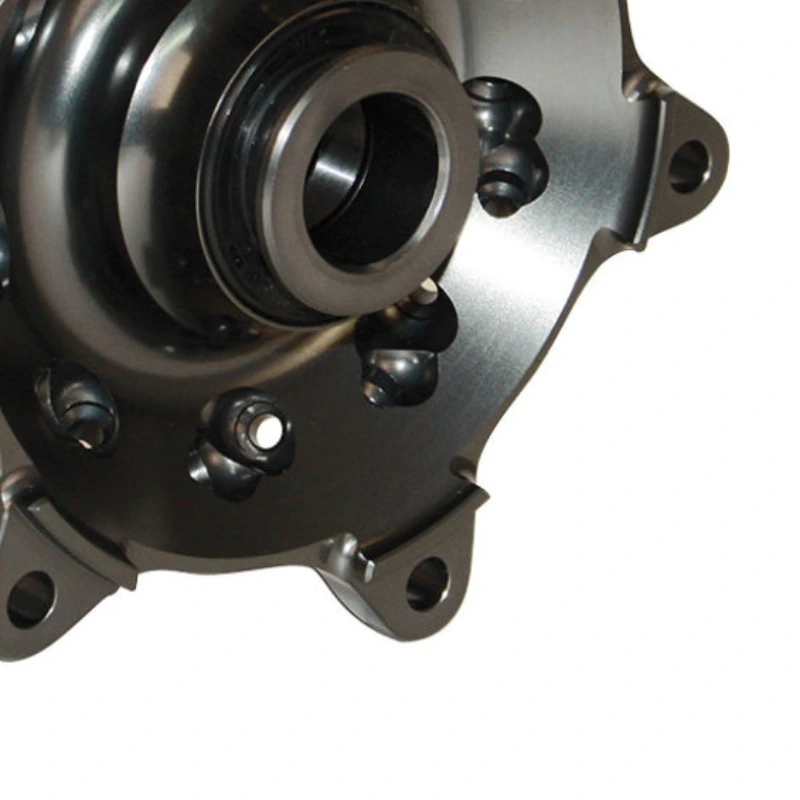

لا يوجد طلاء إضافي، فقط مظهر معدني طبيعي ونظيف مباشرة من CNC.

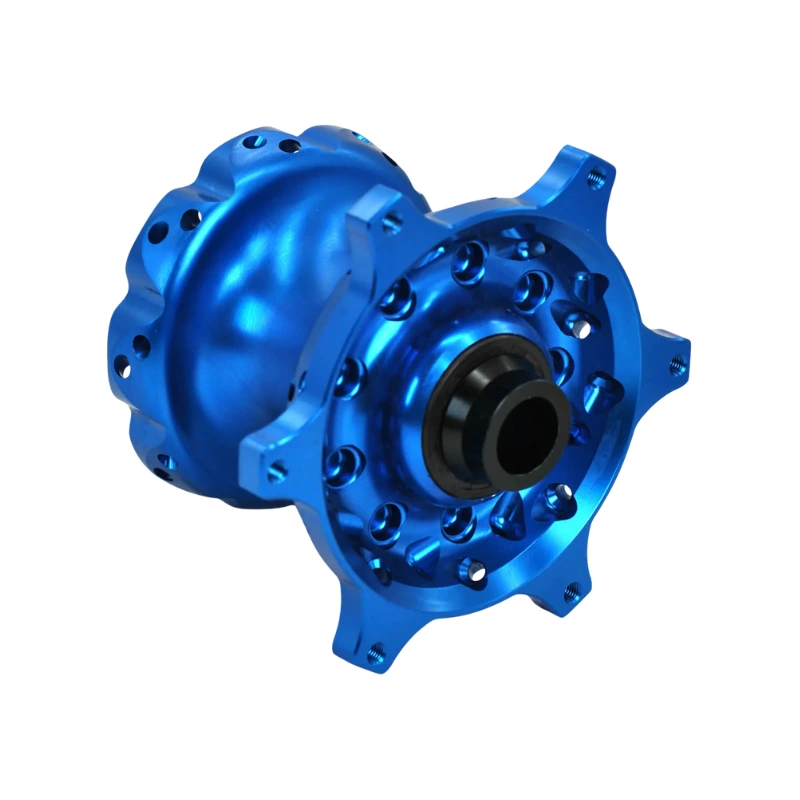

محور العجلة حسب اللون

مجموعة واسعة من الألوان المؤكسدة والمصقولة لتتناسب مع تصميم منتجك أو هوية علامتك التجارية.

أسود

كلاسيكي ومتعدد الاستخدامات. شائع الاستخدام في جميع أنواع المركبات تقريبًا.

فضي

مظهر معدني نظيف مع لمسة نهائية خام أو مصقولة.

أحمر

جريء ورياضي. يُستخدم عادةً في دراجات BMX وMTB ودراجات الأداء العالي.

أزرق

نابض بالحياة وجذاب. لون شائع.

ذهب

مظهر متميز مع لمسة من التباين.

أرجواني / أخضر / برتقالي

متوفر عند الطلب. يُضفي طابعًا فريدًا على تصميمك.

الألوان المخصصة

نحن ندعم التخصيص الكامل للألوان، بما في ذلك التشطيبات المتدرجة.

محور العجلة حسب الميزات

نحن متخصصون في فواصل العجلات المصممة خصيصًا لطرازات سيارات محددة. فيما يلي بعض العلامات التجارية الأكثر طلبًا التي نخدمها.

محاور فرامل القرص

للدراجات ذات الدوارات. قوية، عصرية، ومتينة في جميع الأحوال الجوية.

محاور مزورة

من خلال الجمع بين مزايا التشكيل والتشغيل الآلي باستخدام الحاسب الآلي، فهي متينة ودقيقة.

كيفية تخصيص محور العجلة الأيمن

عند التخطيط لطلب محور عجلات مُصمم خصيصًا من شركة مُصنِّعة مثل HDC، من المهم توضيح مواصفاتك بناءً على التطبيق المُحدد. إليك بعض النصائح لتبسيط الأمور.

1. ابدأ بسيارتك

حدد نوع ونموذج سيارتك: سيارة كارت، أو دراجة جبلية، أو دراجة إلكترونية.

لكلٍّ منها متطلباته الخاصة من حيث التحميل والسرعة والتثبيت. الاختيار بناءً على حالة استخدامك الفعلية سيُضيّق الخيارات بسرعة.

2. تعرف على هيكل المحور الذي تحتاجه

- أمامي أو خلفي

- تحرير سريع أو محور عبر

- فرامل القرص أو فرامل الحافة

تضمن هذه التفاصيل أن المحور يناسب إعدادك ويعمل بالطريقة التي تتوقعها.

3. اختر المادة المناسبة

يوفر الألومنيوم 6061 أداءً قويًا لمعظم أنواع البناء. أما في التطبيقات عالية الضغط، فيُعد الألومنيوم 7075 خيارًا أقوى. كما يتوفر الفولاذ الكربوني لمزيد من المتانة بتكلفة أقل.

قم باختيار المادة بعد دراسة متأنية لعوامل مثل الميزانية ومتطلبات الأداء.

4. ضع في اعتبارك النهاية واللون

من الفضة الخام المصقولة إلى الأحمر أو الأسود المؤكسد، سيُبرز جمالُ محورك جودةَ أدائه. نوفر مجموعةً واسعةً من تشطيبات الأسطح والألوان المُخصصة لتناسب علامتك التجارية أو أسلوب تصميمك.

5. تحدث إلى المورد الخاص بك

سيساعدك المُصنِّع الجيد على التحقق من الأبعاد والتفاوتات والتوافق. لا تتردد في مشاركة رسوماتك أو مواصفاتك الفنية.

هل أنت مستعد لبناء محور العجلة المثالي؟

سواء كان لديك بالفعل رسم أو مجرد فكرة، فنحن هنا لمساعدتك في تحويلها إلى محاور عجلات من الألومنيوم عالية الدقة.

التعليمات

بالتأكيد. يمكننا تصنيع محاور العجلات بناءً على رسوماتك ثنائية/ثلاثية الأبعاد، أو باستخدام الهندسة العكسية من عينة مادية.

بالنسبة لمحاور العجلات CNC المُخصصة، يتراوح الحد الأدنى للطلب لدينا عادةً بين 50 و100 قطعة، حسب درجة التعقيد. تواصل معنا لتزويدنا بمتطلباتك الخاصة.

نحن نعمل بشكل أساسي مع سبائك الألومنيوم 6061 و7075، ولكن الفولاذ الكربوني والتيتانيوم أو مواد أخرى متوفرة أيضًا عند الطلب.

عادةً ما يستغرق الإنتاج من أسبوعين إلى أربعة أسابيع، حسب التصميم والكمية. سنؤكد مدة التسليم بعد مراجعة مشروعك.

نعم، نحن نقدم مجموعة متنوعة من التشطيبات بما في ذلك الأكسدة باللون الأسود والأحمر والفضي والأزرق والذهبي والألوان المخصصة.

نعم. نخدم عملاء عالميين منذ سنوات، ونتمتع بخبرة واسعة في الشحن الدولي والجمارك ووثائق التصدير.

يُفضل أن يكون الرسم مُرفقًا بالأبعاد والمواصفات. إذا لم يكن مُتاحًا، فأرسل لنا فكرتك أو مُنتجك المرجعي، وسنعمل معك لتحديد التفاصيل.