هل تعرف الفرق بين الفولاذ المقاوم للصدأ 304 والفولاذ المقاوم للصدأ 316؟ ولكن هل تعرف أوجه التشابه بينهما؟ في هذه المدونة، سنتحدث عن التعرف على الفولاذ المقاوم للصدأ 304 والفولاذ المقاوم للصدأ 316.

لذا، بحلول نهاية هذا المقال، ستعرف وستتمكن من التعرف بسهولة على ما هو الفولاذ المقاوم للصدأ 304 و316، وأين يختلفان، وكيف يتشابهان، وأين يتم استخدامهما - كل شيء تقريبًا حرفيًا!

ما هو الفولاذ المقاوم للصدأ 304؟

مصدر: بوليكيس

مصدر: بوليكيس

يُعد الفولاذ المقاوم للصدأ 304 أحد أكثر أنواع الفولاذ المقاوم للصدأ شيوعًا. وهو عبارة عن سبيكة من الفولاذ المقاوم للصدأ الأوستنيتي. غالبًا ما يأتي نوع الفولاذ المقاوم للصدأ 304 بنسبة 8 في المائة من النيكل و18 في المائة من الكروم.

ومن المعروف أنها تتمتع بمقاومة ممتازة للتآكل ومقاومة للحرارة وقابلية التصنيع.

ملحوظة: الفولاذ المقاوم للصدأ 304 هو أيضًا ما يُعرف بالفولاذ المقاوم للصدأ 18/8.

ما هو الفولاذ المقاوم للصدأ 316؟

مصدر: الفولاذ الشمبانيا

الفولاذ المقاوم للصدأ 316، مثل الفولاذ المقاوم للصدأ 304، هو أيضًا سبيكة شائعة الاستخدام في مجموعة واسعة من التطبيقات. ومع ذلك، على عكس الفولاذ المقاوم للصدأ 304، يحتوي الفولاذ المقاوم للصدأ 316 أيضًا على كميات ومستويات كبيرة من الموليبدينوم، حوالي 2 إلى 3 في المائة من حيث الوزن.

وبينما يعتبر 304 سبيكة أوستنيتية شائعة، فإن 316 هي السبائك المفضلة للتطبيقات البحرية بسبب مقاومتها العالية للتآكل وقوتها.

الآن أصبحنا نعرف الفارق الرئيسي بينهما. لذا، دعونا نلقي نظرة متعمقة على كل منهما ونكتشف التفاصيل الصغيرة التي تجعلهما مختلفين.

الفولاذ المقاوم للصدأ 304 مقابل الفولاذ المقاوم للصدأ 316: ما الذي يجعلهما مختلفين؟

الفولاذ المقاوم للصدأ، في حد ذاته، يستخدم على نطاق واسع لمتانته. ومع ذلك، من الجيد أن ندرك أن جميع الدرجات ليست متماثلة. الدرجات الأكثر شيوعًا، 304 و316، لها اختلافات رئيسية تؤثر على الأداء في بيئات مختلفة.

شاهد هذا الفيديو من Reliance Foundry الذي يوضح ويفرق بين الفولاذ المقاوم للصدأ 304 والفولاذ المقاوم للصدأ 316.

على الرغم من احتواء كل منهما على الحديد والكروم والنيكل، إلا أن هناك اختلافات قليلة بينهما بسبب تركيبتهما الفريدة. لذا، دعنا نلقي نظرة على الاختلافات بين هذين النوعين من الفولاذ المقاوم للصدأ حتى تتعرف عليهما جيدًا!

تعبير

الفرق الأكبر وربما الأكثر شيوعًا بين الفولاذ المقاوم للصدأ 304 و 316 هو إضافة الموليبدينوم إلى 316.

يضيف هذا العنصر مقاومة للتآكل، وخاصة ضد الكلوريدات والبيئات الحمضية. يحتوي كلا السبائك على الكروم 18% والنيكل 8% على الأقل، ولكن 316 يحتوي عادةً على 2-3% الموليبدينوم، بينما يفتقر 304 إلى هذا المكون.

ملحوظة: هذا التمييز وحده هو ما يجعل الفولاذ المقاوم للصدأ 316 الخيار المفضل للظروف القاسية.

ملكيات

بالطبع، وجود اختلاف في التركيبة من شأنه أن يؤدي إلى اختلاف في خصائصهما أيضًا. على الرغم من أن كلا الدرجتين قويتان وطويلتا الأمد ومقاومتان للصدأ، إلا أن 316 يعمل بشكل أفضل في الظروف الصعبة.

نظرًا لمقاومته للتآكل والتآكل الناتج عن الشقوق، فهو مثالي للتطبيقات الكيميائية والبحرية. وعلى النقيض من ذلك، فإن الفولاذ المقاوم للصدأ 304 أسهل في التصنيع وبأسعار معقولة، مما يجعله مناسبًا للاستخدام على نطاق واسع. كما يتمتع بنقطة انصهار أعلى من الفولاذ المقاوم للصدأ 316!

كلاهما مقاومان للغاية للحرارة، ولكن 316 يتحمل بشكل أفضل عند تعرضه لمواد تآكلية لفترات أطول.

التطبيقات

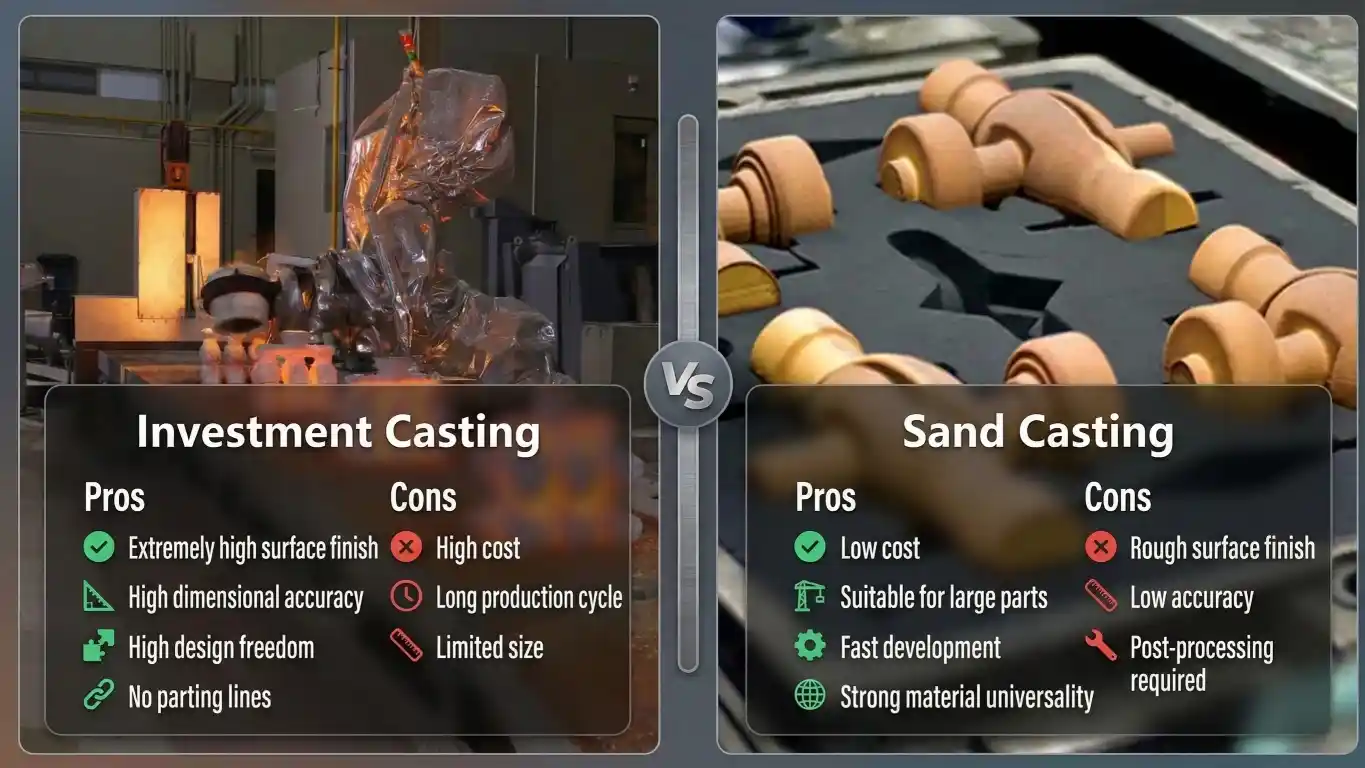

لقد جعلت شركة JC Casting حياتنا أسهل! لقد قامت بتصميم هذه الصورة البسيطة لمساعدتنا على فهم الاختلافات والتشابهات الأساسية بين الفولاذ المقاوم للصدأ 304 و316 بشكل أفضل.

مصدر: جي سي كاستنج

مصدر: جي سي كاستنج

يُستخدم الفولاذ المقاوم للصدأ 304 بشكل متكرر في الأجهزة المنزلية وزخارف السيارات وأدوات المطبخ. وهو خيار رائع للبيئات الخارجية والداخلية المعتدلة نظرًا لسعره وسهولة اللحام.

من ناحية أخرى، تعد مادة 316 المادة المفضلة لمرافق المعالجة الكيميائية والمعدات الطبية والمباني البحرية. فهي تتحمل التعرض للمواد الكيميائية الشديدة والمياه المالحة بسبب مقاومتها الاستثنائية للتآكل.

لذا، كما ترون، هناك فرق كبير من حيث كيفية استخدامها والصناعات التي يمكنها خدمتها.

سعر

وبالطبع، دعونا نتحدث عن الأسعار. نعلم جميعًا الآن أن الفولاذ المقاوم للصدأ 316 يحتوي على الموليبدينوم، لذا فمن الطبيعي أن يكون أكثر تكلفة. يكلف الفولاذ المقاوم للصدأ 316 أكثر من الفولاذ المقاوم للصدأ 304 - بسبب الموليبدينوم المضاف.

ومع ذلك، يختلف فارق السعر وفقًا لظروف السوق وتكاليف المواد الخام. وفي حين أن 304 أكثر ملاءمة للميزانية للتطبيقات العامة، فإن الاستثمار في 316 أمر منطقي للمشاريع التي تتطلب متانة طويلة الأمد في البيئات القاسية.

ناهيك عن حقيقة أن الفولاذ المقاوم للصدأ 316 قابل للتطبيق في العديد من الصناعات التي قد لا يكون استخدام 304 مناسبًا لها.

أين يمكن الحصول على الفولاذ المقاوم للصدأ عالي الجودة

لا شك أنك ستتمكن من شراء الفولاذ المقاوم للصدأ 304 أو 316 في أي مكان حول العالم. ومع ذلك، ما عليك التأكد منه هو الجودة التي ستحصل عليها.

لن يخبرك العديد من المصنعين بكيفية تصنيع أو الحصول على الفولاذ المقاوم للصدأ 304 أو 316. ورغم أن معظم العمليات التي تتم في هذا الصدد ليست مهمة حقًا، فمن الضروري معرفة كيفية القيام بذلك حتى تعرف ما تتوقعه.

هنا معنا في تصنيع HDCنحن شفافون في جميع العمليات وجهود التصنيع التي نقوم بها.

Why HDC Manufacturing is Your Partner For Custom Stainless Steel Products

Stainless steel types have varying degrees of effectiveness and durability. While it’s common knowledge that not all stainless steels are made equally, you can be sure that we here at HDC Manufacturing are able to provide the best and highest quality of stainless steel for whatever your custom project is.

لا تقتصر منتجاتنا من الفولاذ المقاوم للصدأ على ما تعرفه عنها فحسب. فنحن نقدم مجموعة كبيرة من الفولاذ المقاوم للصدأ، بما يتناسب مع احتياجاتك!

لن تواجه أبدًا أي نقص في المعادن أو السبائك عندما تعمل معنا! فقط أخبرنا ما تحتاجه وسنكون سعداء جدًا بتقديم المساعدة التي تبحث عنها!