النحاس هو سبيكة معدنية مستخدمة على نطاق واسع وتشتهر بجاذبيتها الجمالية ومتانتها وتعدد استخداماتها في تطبيقات مختلفة. من العناصر الزخرفية والآلات الموسيقية إلى تركيبات السباكة والأدوات البحرية، اكتسب النحاس سمعة طيبة باعتباره مادة موثوقة.

ومع ذلك، غالبًا ما تثار أسئلة حول مقاومته للصدأ ومدى قدرته على الصمود في مواجهة العوامل البيئية. ستستكشف هذه المقالة الأسباب الرئيسية لصدأ المعادن، وكيف يختلف النحاس الأصفر ويتشابه مع المعادن الأخرى والأهم من ذلك، ما إذا كان النحاس الأصفر يصدأ أم لا؟

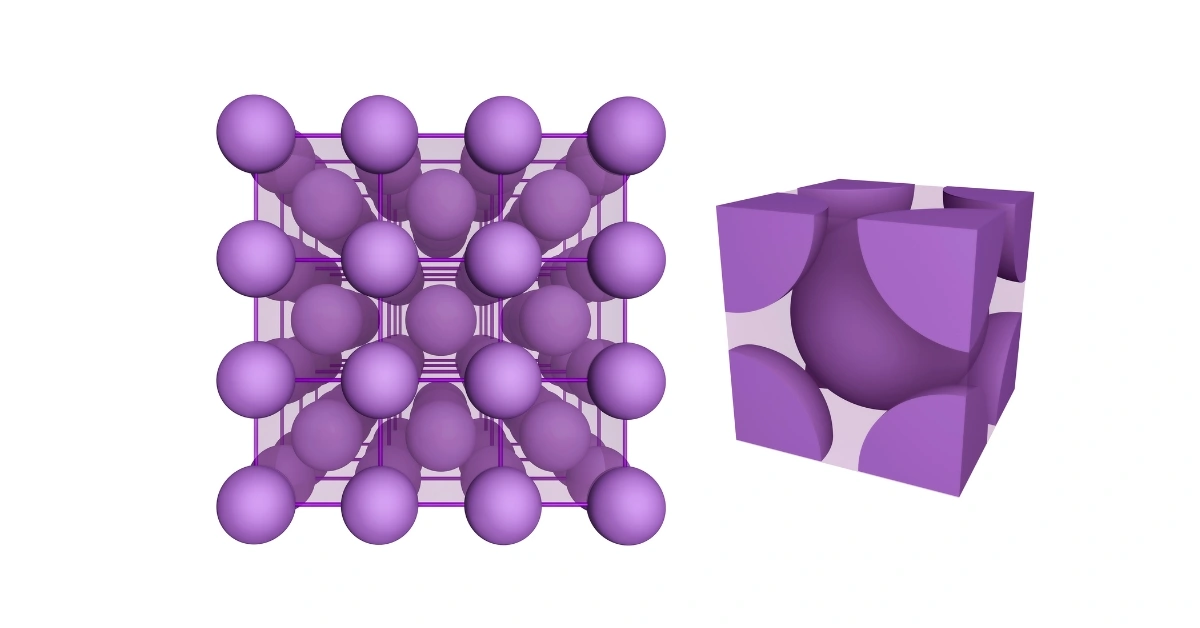

فهم النحاس وتركيبه

النحاس هو سبيكة مكونة في المقام الأول من نحاس و الزنكمع إضافة كميات ضئيلة من عناصر أخرى مثل الرصاص أو القصدير أو الألومنيوم من حين لآخر لتعزيز خصائص معينة. لونه الذهبي المميز يجعله خيارًا شائعًا للتطبيقات الزخرفية وغيرها حيث تكون الجماليات ذات أهمية.

على عكس المعادن الحديدية مثل الحديد والصلب، والتي هي عرضة للصدأ بسبب محتواها من الحديد، النحاس هو بطبيعته غير حديديوهذا يعني أنه لا يحتوي على الحديد، وهو عنصر أساسي يسبب الصدأ على المعادن والسبائك المعدنية. الصدأ هو في الأساس أكسيد الحديد، والتي تتكون عندما يتفاعل الحديد مع الأكسجين والرطوبة. ولأن النحاس يفتقر إلى الحديد، فإنه لا يمكن أن يصدأ من الناحية الفنية. ومع ذلك، هذا لا يعني أن النحاس محصن ضد جميع أشكال التآكل أو تغير اللون.

مقارنة تآكل النحاس: التشويه مقابل الصدأ

على الرغم من أن النحاس لا يصدأ، إلا أنه يمكن أن يخضع لنوع مختلف من التفاعل الكيميائي المعروف باسم التشويه. يحدث التشويه عندما يتعرض النحاس للهواء أو الرطوبة أو المواد الكيميائيةيؤدي ذلك إلى ظهور طبقة سطحية من الأكسدة. وينتج عن ذلك مظهر باهت أو داكن، وغالبًا ما يكون مصحوبًا برواسب خضراء أو زرقاء. ويحدث تلطيخ النحاس في المقام الأول بسبب تفاعل محتواه من النحاس مع الأكسجين والعناصر البيئية الأخرى.

الأخضر طبقة نحاسية التي تتشكل على النحاس، والتي يشار إليها غالبًا باسم زنجار، هو نتيجة لأكسيد النحاس أو كربونات النحاس. في حين أنه قد لا يؤثر على سلامة هيكل النحاس، فإن التشويه غير جذاب جماليًا لبعض المستخدمين ويتطلب التنظيف الدوري للحفاظ على اللمعان الأصلي للسبائك. على عكس الصدأ، الذي يمكن أن يضعف المادة بمرور الوقت، فإن التشويه يكون سطحيًا بشكل عام ويمكن إزالته من خلال التلميع.

العوامل البيئية المؤثرة على تآكل النحاس

يتمتع النحاس بمقاومة ممتازة للتآكل في ظل الظروف العادية، ولكن أداءه قد يختلف حسب البيئة. يؤدي التعرض الطويل للهواء والرطوبة إلى تسريع عملية التشويه، حيث تشجع البيئات الرطبة بشكل خاص على تكوين طبقة خارجية على أسطح النحاس.

هذا هو السبب وراء ظهور طبقة خضراء مميزة على العناصر النحاسية التي تُترك في الهواء الطلق بمرور الوقت. في المناطق البحرية أو الساحلية، يتعرض النحاس لمياه البحر والهواء المحتوي على مستويات عالية من أيونات الكلوريد، والتي يمكن أن تؤدي إلى شكل من أشكال التآكل المعروف باسم إزالة الزنكتؤدي هذه العملية إلى تسرب الزنك من السبائك، مما يترك وراءه بنية ضعيفة غنية بالنحاس.

وبالمثل، يمكن أن يؤدي التعرض للمواد الحمضية إلى تسريع عملية التشويه وتقليل عمر السبائك. كما تساهم البيئات الحضرية ذات المستويات العالية من تلوث الهواء في التشويه بسبب وجود مركبات الكبريت في الهواء. تتفاعل هذه المركبات مع النحاس في النحاس الأصفر، لتكوين كبريتيد النحاس، الذي يظهر كطبقة سطحية داكنة أو مسودة، مما يؤثر على الجاذبية الجمالية للمعدن ومتانته.

لذلك، من المهم للغاية الحفاظ على المنتجات النحاسية في أفضل حالاتها لتجنب أي تشويه أو أي شكل آخر من أشكال التآكل الذي يمكن أن يقلل من جاذبيتها.

كيفية منع ومعالجة تشويه النحاس؟

للحفاظ على مظهر النحاس ومنع التشوه المفرط، يمكن اتباع بعض الممارسات الأفضل:

- التنظيف المنتظم

يساعد مسح الأسطح النحاسية بقطعة قماش ناعمة ومنظف خفيف على إزالة الأوساخ والزيوت والبقايا البيئية التي تساهم في التشويه. تجنب المواد الكاشطة التي يمكن أن تخدش المعدن.

- الطلاءات الواقية

يمكن أن يوفر وضع طلاء شفاف أو مادة مانعة للتسرب حاجزًا وقائيًا يمنع الهواء والرطوبة من ملامسة النحاس مباشرة. وهذا مفيد بشكل خاص للعناصر النحاسية المعرضة لظروف بيئية قاسية.

- تلميع

يمكن أن يؤدي التلميع الدوري باستخدام مواد التنظيف المخصصة للنحاس إلى استعادة لمعانه الطبيعي وإزالة الأكسدة السطحية. من المهم متابعة ذلك بطبقة واقية لإطالة عمر اللمعان.

- بيئة خاضعة للرقابة

يؤدي تخزين العناصر النحاسية في بيئة داخلية خاضعة للرقابة مع الحد الأدنى من الرطوبة والملوثات إلى تقليل خطر التشويه وإزالة الزنك.

لماذا يعتبر النحاس مادة مفضلة على الرغم من التشوه

على الرغم من قابليته للتشوه، يظل النحاس الأصفر ذا قيمة عالية نظرًا لتعدد استخداماته ومتانته وخصائصه الجمالية. وعلى عكس الصدأ، الذي يضر بسلامة الهياكل المعدنية الحديدية، فإن تشوه النحاس الأصفر يكون سطحيًا ويمكن التحكم فيه. وعلاوة على ذلك، فإن مقاومة النحاس الأصفر للصدأ تلغي الحاجة إلى الطلاءات الواقية المكثفة أو المعالجات التي غالبًا ما تكون مطلوبة للمواد القائمة على الحديد.

في التطبيقات التي يكون فيها كل من الوظيفة والمظهر أمرًا بالغ الأهمية، يوفر النحاس توازنًا ممتازًا. تتيح قابليته للتصنيع تصميمات دقيقة ومعقدة، في حين تضمن مقاومته للتآكل طول العمر في البيئات الصعبة.

الخاتمة: فهم النحاس ومتانته

للإجابة على السؤال، هل يصدأ النحاس؟الإجابة المباشرة هي لا. النحاس، كونه معدنًا غير حديدي، لا يحتوي على الحديد وبالتالي فهو محصن ضد الصدأ. ومع ذلك، فهو ليس محصنًا تمامًا ضد العوامل البيئية ويمكن أن يتعرض للتشويه أو إزالة الزنك في ظل ظروف معينة.

اكتشف المزيد مع منشورات مدونتنا.

المشاركات الاخيرة

اكتشف المزيد عن منتجاتنا

منتجات HDC

اقتباس فوري!