إن معرفة وفهم درجة انصهار الفولاذ المقاوم للصدأ أمر بالغ الأهمية، خاصةً إذا كنت تعمل حاليًا في صناعات تعتمد بشكل كبير على الفولاذ المقاوم للصدأ. بالإضافة إلى ذلك، سيعتمد الأمر أيضًا على العديد من الخصائص والعوامل المختلفة في صناعة المعادن والسبائك.

في هذه المدونة، سنتحدث عن نقطة انصهار الفولاذ المقاوم للصدأ وكل ما يتعلق بها لمساعدتك على فهمها بشكل أفضل!

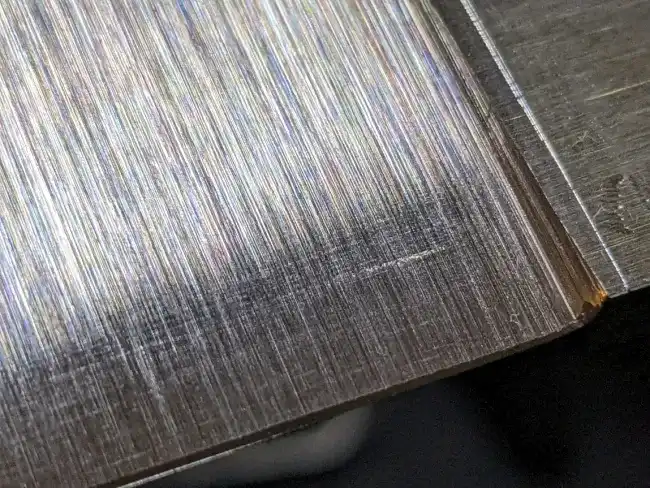

فهم خصائص الفولاذ المقاوم للصدأ

مصدر: كونرو

كما هو الحال مع جميع السبائك الأخرى، يتميز الفولاذ المقاوم للصدأ بخصائصه الخاصة. فهو سبيكة مصنوعة من الحديد والكروم والنيكل، ويتميز بمقاومته للتآكل ومتانته. يُشكل محتوى الكروم طبقة أكسيد واقية، تمنع الصدأ وتُعزز متانته.

من ناحية الخصائص الميكانيكيةيتمتع الفولاذ المقاوم للصدأ بقوة شد عالية، مما يسمح له بتحمل الأحمال الثقيلة دون تشوه.

تختلف صلابته باختلاف تركيبه ومعالجته الحرارية، وتُعدّ درجات المارتنسيت هي الأكثر صلابة. تتراوح درجة انصهاره بين 1370 و1530 درجة مئوية، حسب نوع السبيكة، وسنتحدث عن ذلك لاحقًا.

تبلغ كثافته عادةً حوالي 7.9 غ/سم³، مما يضمن توازنًا بين القوة والوزن. هذه الخصائص تجعل الفولاذ المقاوم للصدأ الخيار الأمثل للبيئات التي تتطلب المتانة ومقاومة الحرارة وطول العمر.

ملحوظة: توفر درجات الفولاذ المقاوم للصدأ المختلفة مستويات متفاوتة من الصلابة والقوة والمقاومة لدرجات الحرارة القصوى، مما يجعلها مثالية للتطبيقات الصناعية والطبية والهيكلية

Stainless Steel Melting Point: How Hard is It to Melt?

خلافًا للاعتقاد السائد، يتطلب صهر الفولاذ المقاوم للصدأ أكثر من مجرد وضعه في النار. تتراوح درجة انصهاره، حسب نوعه، بين 1370 و1530 درجة مئوية (2498 و2786 درجة فهرنهايت)، مما يعني أنه يحتاج إلى حرارة عالية ليذوب.

يتم الوصول إلى هذه درجات الحرارة عادة في الأفران الصناعية، مثل أفران القوس الكهربائي أو الحث، مما يجعل الصهر في المنزل أو على نطاق صغير مستحيلا عمليا دون معدات متخصصة.

تكمن صعوبة صهر الفولاذ المقاوم للصدأ في تركيبته. فالكروم والنيكل وعناصر السبائك الأخرى تُعزز مقاومته للحرارة، مما يُحافظ على استقراره الهيكلي حتى في الظروف القاسية.

ما هي نقطة انصهار الفولاذ المقاوم للصدأ 316L؟

يتميز الفولاذ المقاوم للصدأ 316L بانخفاض محتواه من الكربون ومقاومته المعززة للتآكل، وله نقطة انصهار تتراوح من 1375 درجة مئوية إلى 1400 درجة مئوية (2507 درجة فهرنهايت إلى 2552 درجة فهرنهايت).

إليكم مقطع فيديو يعلمك كيفية التحقق بشكل صحيح من الفولاذ المقاوم للصدأ 316L!

ويرجع هذا النطاق المنخفض قليلاً من الانصهار، مقارنة بدرجات الفولاذ المقاوم للصدأ الأخرى، إلى تركيبته الكيميائية المحددة.

في البيئات الصناعية، يتطلب تحقيق هذه درجات الحرارة معدات متخصصة، مثل أفران القوس الكهربائي أو الحث، لضمان التحكم الدقيق أثناء عمليات الصهر والصب.

ما هو الفولاذ المقاوم للصدأ الذي يمكنه مقاومة أعلى درجات الحرارة؟

من بين العديد من درجات الفولاذ المقاوم للصدأ المختلفة، تعد 309 و310 من بين الدرجات التي تتمتع بأفضل وأعلى مقاومة لدرجات الحرارة.

الفولاذ المقاوم للصدأ 309 يتميز بدرجة حرارة متقطعة تبلغ 980 درجة مئوية ودرجة حرارة مستمرة تبلغ 1095 درجة مئوية، بينما يتميز 310 بدرجة حرارة متقطعة تبلغ 1035 درجة مئوية ودرجة حرارة مستمرة تبلغ 1150 درجة مئوية.

وهذا يعني أساسًا أنه لكي تذوب، يجب أن تكون درجة الحرارة أعلى من درجة الحرارة المتقطعة لتلك الحالات، ودرجة حرارة مستمرة لقدرتها على الاحتراق والذوبان المستمر.

ما هي كمية الحرارة التي يستطيع الفولاذ المقاوم للصدأ 304 أن يتحملها؟

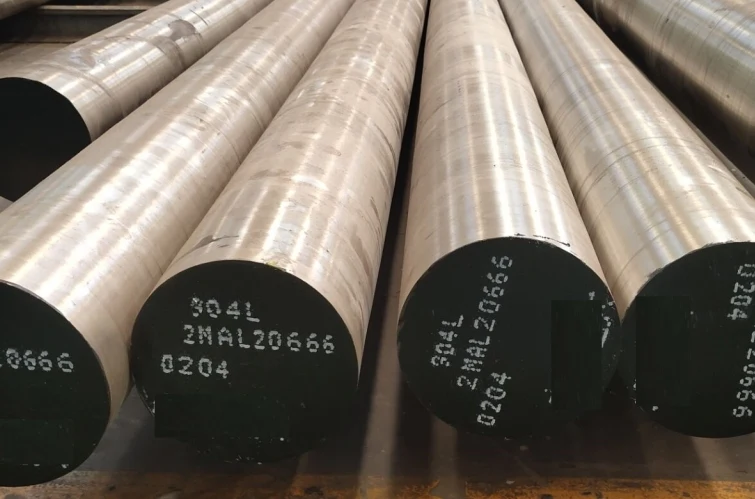

مصدر: يو باي في

يتحمل الفولاذ المقاوم للصدأ 304 درجات حرارة تصل إلى 870 درجة مئوية (1598 درجة فهرنهايت) لفترات قصيرة و925 درجة مئوية (1697 درجة فهرنهايت) أثناء الاستخدام المتواصل. ومع ذلك، قد تقل مقاومته للتآكل نتيجة التعرض لفترات طويلة لدرجات حرارة تتراوح بين 425 و860 درجة مئوية (797 و1580 درجة فهرنهايت).

بسبب مقاومته لترسب الكربيد، فإن 304L هو ما يوصي به معظم الخبراء في هذه المواقف.

لماذا يتم التعبير عن نقاط الانصهار على شكل نطاق؟

منذ المراحل المبكرة لتحديد هذه الأنواع من البيانات، كان من الصعب للغاية التوصل إلى تفاصيل محددة لتحديد درجات الحرارة الدقيقة لنقاط الانصهار.

ولذلك توصل الخبراء والمهندسون والعلماء إلى طريقة لتحديد درجة انصهار المركبات من خلال النطاقات.

تذوب معظم المواد ضمن نطاقات حرارية صغيرة. علاوة على ذلك، تتزايد الشوائب وتتسع في هذا النطاق.

نقطة انصهار الألومنيوم

بما أن الألومنيوم والفولاذ المقاوم للصدأ من المواد التي تُقارن عادةً، فهل درجة انصهار الألومنيوم أعلى أم أقل؟ درجة انصهار الألومنيوم أقل بكثير من درجة انصهار الفولاذ المقاوم للصدأ، حيث تبلغ 660.3 درجة مئوية أو 1220.54 درجة فهرنهايت.

فهو من أدنى المعادن مقارنة بالمواد في نفس عياره مثل النحاس والنحاس الأصفر والحديد.

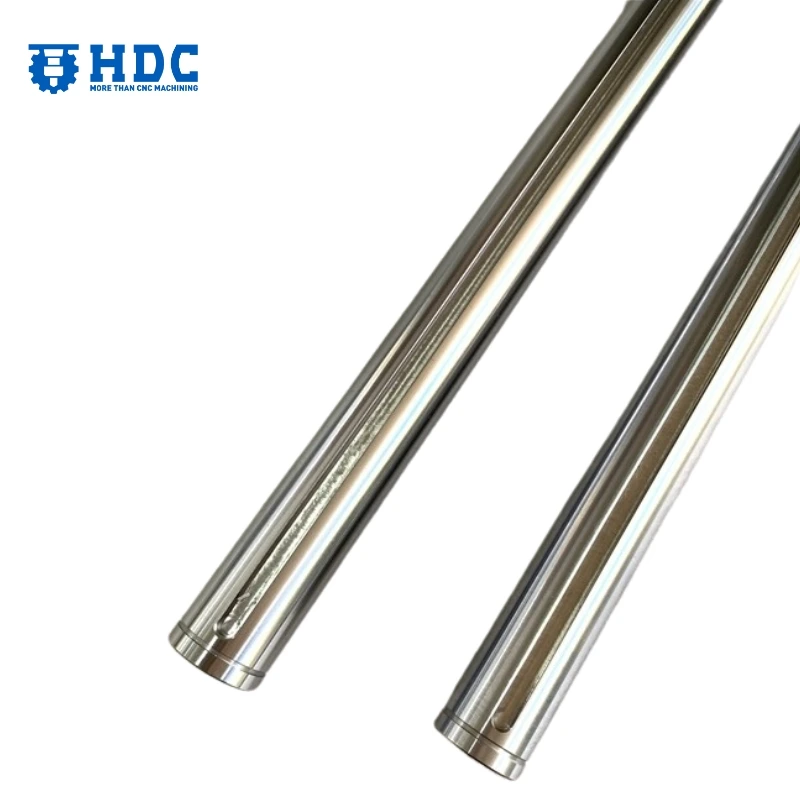

HDC Manufacturing’s Stainless Steels as the Best in China

في الوقت الحاضر، لم يعد العثور على فولاذ مقاوم للصدأ عالي الجودة أمرًا صعبًا. يمكنك زيارة أي مصنع أو تاجر محلي والحصول على فولاذ مقاوم للصدأ عالي الجودة.

However, if you’re buying in wholesale, it’s best to go with a stainless steel manufacturer and supplier you can trust. Here in China, we at HDC Manufacturing have been regarded as the best and most trustworthy مصنع الفولاذ المقاوم للصدأ منذ أوائل عام 2010.

Our business has been focused on B2B, providing stainless steel plates, rods, and even sheets to businesses that need them. So, if you find yourself in need of high-quality stainless steel, you can count on us here at HDC Manufacturing!

احصل على تقدير مجاني اتصل بنا أو راسلنا! احصل على طلباتك في أقل من 3 أشهر!