أفضل شركات التشكيل في الصين 2025: دليل شامل

- بواسطة: HDCMFG

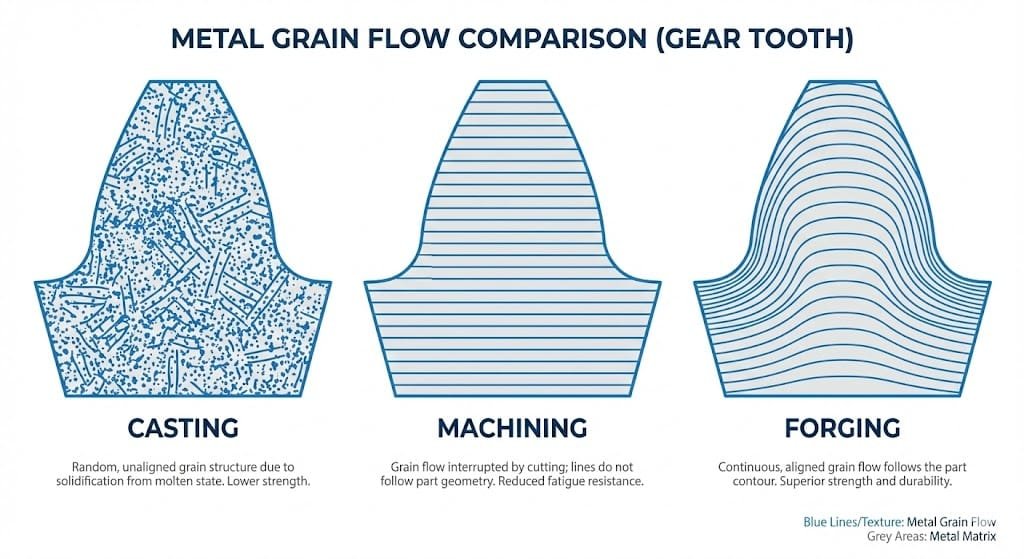

التشكيل ليس مجرد تشكيل المعدن. كلا! التشكيل علم متكامل يجمع بين القوة والدقة والموثوقية. بحلول عام ٢٠٢٥، ستنتشر في الصين العديد من شركات التشكيل، مقدمة خدماتها في جميع أنحاء العالم. سواءً كنت ترغب في مكونات صناعية ثقيلة، أو قطع ألومنيوم خفيفة الوزن، أو حواف متينة، فإن الصين تضم أفضل مصنعي التشكيل في العالم.

في هذه المدونة، سنناقش أفضل ثماني شركات تشكيل في الصين، وتخصصاتها، وأيها قد تكون الشريك الأمثل لمشروعك. لذا، ابقَ على اتصال!

1) شركة شاندونغ برايم للتجارة الدولية المحدودة

نظرة عامة على الشركة

شركة شاندونغ برايم للتجارة الدولية المحدودة هي شركة ناشئة في مقاطعة شاندونغ الصينية، تُعرف أيضًا باسم برايم للقطع المخصصة. مع تطور التقنيات الحديثة، وسّعت برايم خدماتها، حيث تُقدّم خدمات التشكيل بالطرق، والختم، والتشغيل الآلي باستخدام الحاسب الآلي (CNC)، والمعالجة الحرارية، وتشطيب الأسطح. لذا، ستحصل على جميع الخدمات في مكان واحد.

قدرات التشكيل

- يعمل برايم مع الكثير من المواد مثل الفولاذ السبائكي، والفولاذ الكربوني، والفولاذ المقاوم للصدأ، وسبائك الألومنيوم.

- هنا يمكنك الحصول على خدمات التشكيل بالقالب المفتوح، والتشكيل بالحلقات المدلفنة، والتشكيل بالقالب المغلق، والتشكيل بالضغط.

- أنها تسمح بالإنتاج بكميات قليلة ومرتفعة.

- يبدأ الحد الأدنى لكمية الطلب من 100 قطعة.

مرحلة ما بعد المعالجة

تقدم برايم أيضًا خدمات ما بعد التشكيل، مثل المعالجة الحرارية والطلاء والتشطيب. تنتج ماكيناتها عالية الجودة ذات التحكم الرقمي (CNC) قطعًا بتفاوتات دقيقة. علاوة على ذلك، تعزز عمليات مثل التبريد والتسخين قوة القطع.

الجودة والصناعات

جميع منتجات برايم معتمدة وفقًا للمعايير الدولية، وتقدم شهادات وتقارير فحص. تُورّد برايم قطع غيار الآلات، ووصلات الأنابيب، وغيرها من القطع في جميع أنحاء العالم، بما في ذلك أمريكا الشمالية والشرق الأوسط وأوروبا.

2) شانشي هونغكاي تزوير المحدودة

نظرة عامة على الشركة

تقع شركة شانشي هونغكاي للتشكيل المحدودة في مقاطعة دينغشيانغ، مقاطعة شانشي. تُعرف هذه المنطقة غالبًا بـ"موطن التشكيل". يتميز موقع الشركة بموقع استراتيجي، حيث يسهل الوصول إلى جميع مصادر الطاقة والمواد الخام، مما يضمن كفاءة إنتاج عالية.

قدرات الإنتاج

تقدم الشركة العديد من الخدمات، مثل التشغيل الآلي، والتشكيل، والمعالجة الحرارية، ومعالجة الأسطح، والشحن. وتكمن قوتها الرئيسية في الفلانشات التي تصنعها.

- إنهم يقدمون لحام الرقبة، واللحام الملولب، ولحام المقبس، ولحام الحواف المتداخلة.

- تتم عملية التشكيل الخاصة بهم وفقًا للمعايير الدولية، على سبيل المثال، ANSI، وDIN، وJIS.

- إنهم يقدمون مجموعة واسعة من أحجام المنتجات من صغيرة جدًا إلى كبيرة جدًا.

- علاوة على ذلك، فإنهم يقدمون أيضًا خدمات المعالجة والتشطيب بعد التشكيل.

الجودة والشهادات

لديهم مختبرات للاختبارات الفيزيائية والكيميائية، وكل شيء يخضع لفحص دقيق. علاوة على ذلك، ستحصلون على تغليف متناسق. بفضل جودة منتجاتهم العالية، اكتسبوا ثقة العملاء من جميع أنحاء العالم.

التصدير والوصول إلى السوق

تُصدّر هونغكاي منتجاتها إلى أوروبا والولايات المتحدة الأمريكية ومناطق أخرى. وتحظى حوافها ومنتجاتها المزورة الأخرى بتقدير عالمي.

3) شركة الصين الأولى للصناعات الثقيلة (CFHI)

نظرة عامة على الشركة

تأسست شركة CFHI عام ١٩٥٤، وهي من أقوى الشركات المملوكة للدولة في الصين. تُعرف أيضًا باسم YiZhong. تُركز شركة China First Heavy Industry بشكل كبير على التشكيل بالطرق، بالإضافة إلى تصنيع السفن والمعدات الثقيلة الأخرى.

قدرات التشكيل والتصنيع

- تشتهر شركة CFHI بخدمات التشكيل. وهي مجهزة بمكبس هيدروليكي مفتوح القالب بسعة 15,000 طن. والجدير بالذكر أنها كانت تُعتبر في السابق من أكبر المكبسات في العالم.

- يُنتجون قطعًا مُشكَّلة للطاقة النووية، مثل دوارات التوربينات، وأوعية ضغط المفاعلات، وغيرها.

- وبمساعدة عملية التشكيل بالطرق، فإنهم ينتجون أيضًا أجزاء أخرى للبنية التحتية للنقل، ومصانع الصلب، ومصانع البتروكيماويات.

الإنجازات الأخيرة

من الجدير بالذكر أن شركة CFHI قامت مؤخرًا بتشكيل أكبر دوار نووي في العالم (حوالي 700 طن). وهذا يُظهر قدرة شركة CHFI على خدمة المشاريع الضخمة.

الجودة والابتكار

كما تعلمون، تتطلب مكونات الطاقة النووية رقابة صارمة على الجودة، وتتولى CHFI هذه المهمة. جميع المنتجات مطابقة للمعايير الدولية تمامًا.

بالإضافة إلى ذلك، لديهم خبرة في إنتاج كميات كبيرة من القوالب المفتوحة، وهي نقطة إيجابية للصناعات التي ترغب في تصنيع أجزاء هيكلية كبيرة.

نطاق الأعمال والأهمية الاستراتيجية

تُركز شركة CHFI بشكل رئيسي على قطاعي الطاقة والدفاع. وتُستخدم قطعها المُشكّلة في محطات الطاقة النووية، حيث تُشكّل الطاقة النووية جزءًا كبيرًا من أعمالها.

4) مجموعة بينتيجين (تشكيل المعادن)

نظرة عامة على الشركة

تعمل شركة PinTeJin تحت العلامة التجارية Metal Forging، ومقرها هومين، مدينة دونغقوان. تأسست الشركة عام ١٩٩٥، وتُعتبر الآن من أكثر شركات التشكيل تنوعًا في الصين.

قدرات التشكيل والتصنيع

- تقدم الشركة خدمات التشكيل بالطرق الساخنة والتشكيل بالطرق الباردة والتشكيل بالحلقات والتشكيل بالقالب.

- وهي مجهزة بمكابس مثل 160T وأيضًا 4000T.

- علاوة على ذلك، لديهم ورشة أدوات للتشكيل والقوالب. لذا، لا داعي للقلق بشأن التصاميم المخصصة.

- يُذكر أن مساحة إنتاجهم تبلغ حوالي 30 ألف متر مربع، ويعمل لديهم ما يقارب 200 عامل وحوالي 35 فنيًا.

مرحلة ما بعد المعالجة والاختبار

- تقدم شركة PinTeJin خدمات ما بعد التشكيل، مثل التشذيب، والتشطيب، والتدفئة، وما إلى ذلك.

- علاوة على ذلك، لضمان الجودة، فإنهم يستخدمون مقاييس الدبوس، وأدوات التفتيش، وآلات قياس الإحداثيات.

الشهادات والمعايير

- حصلت شركة PinTeJin على شهادة ISO 9001 وIATF.

- علاوة على ذلك، فقد حصلوا على جائزة "التشكيل عالي الجودة" من قبل جمعية التشكيل الصينية.

5) شركة ووهو سانليان للتزوير المحدودة

نظرة عامة على الشركة

تقع الشركة في مدينة ووهو، مقاطعة آنهوي، الصين. تتمتع شركة ووهو سانليان المحدودة للتشكيل بسمعة طيبة في قطاع التشكيل. وهي شركة مساهمة عامة، تخدم العديد من القطاعات منذ سنوات طويلة.

قدرات التشكيل والتصنيع

- تتمتع شركة سانليان بـ 20 خط إنتاج للتزوير.

- وبشكل عام، يبلغ إنتاجهم السنوي من التشكيل حوالي 40 ألف طن.

- لديهم ما يقارب 600 موظف، ولديهم مصنع كبير للتشكيل.

المعدات والتكنولوجيا

- إذا تحدثنا عن مكابس التشكيل الخاصة بهم، فإن لديهم مكابس حرارية 630T، و1000T، و1600T، و2500T.

- كما أن لديهم قدرات صب جيدة، مثل أفران التبريد الفراغي، وأفران النترجة، ومخرطات CNC، ومخرطات عمودية.

- وبالإضافة إلى ذلك، لديهم أيضًا آلات اختبار، ومجاهر معدنية، وأجهزة قياس الإحداثيات، وأجهزة قياس الطيف.

الشهادات والمعايير

سانليان حاصلة على شهادة TS16949. وهي شهادة مهمة لموردي قطع غيار السيارات، إذ تضمن جودة ثابتة.

المنتجات والتطبيقات

- أعمدة الكرنك، أعمدة التوازن، قضبان التوصيل

- مفاصل التوجيه، أذرع التحكم، مفصلات الأبواب

- أعمدة النقل والأجزاء الهيكلية

6) شركة جييتا لقطع غيار السيارات المحدودة

نظرة عامة على الشركة

تأسست شركة غيتا لقطع غيار السيارات المحدودة عام ٢٠٠٦، وهي شركة رائدة في مجال التشكيل والتشغيل الآلي في الصين. تركز الشركة بشكل رئيسي على قطع غيار أنظمة التعليق وتوجيه السيارات. بحلول عام ٢٠٢٥، ستقدم غيتا خدماتها لمختلف القطاعات حول العالم.

قدرات التشكيل والتصنيع

- تتميز هذه القطع بتشكيل واسع النطاق يتبعه تشغيل آلي. تتميز أجزاؤها بتحمل دقيق وتشطيب ممتاز.

- يستخدمون في الغالب الفولاذ أو السبائك عالية القوة أو الفولاذ الكربوني.

نطاق الأعمال والأهمية الاستراتيجية

تصدر شركة جييتا منتجاتها إلى مختلف أنحاء العالم، بما في ذلك الولايات المتحدة الأمريكية وأوروبا والشرق الأوسط وجنوب آسيا.

الشهادات والمعايير

شركة غييتا حاصلة على شهادة ISO/TS 16949 (الآن IATF). كما تمتلك مختبرات داخلية لضمان مطابقة جميع منتجاتها للمعايير المطلوبة.

المنتجات والتطبيقات

- وصلات الكرة، أطراف قضيب الربط، وصلات التثبيت

- أذرع التحكم، الوصلات، محامل نهاية القضيب

- قطع غيار مخصصة

- مكونات العمود، وصلات الوصلات، والمسبوكات الهيكلية الأخرى

7) شركة ووشي هيندرتشان الصناعية المحدودة.

نظرة عامة على الشركة

تأسست شركة HDC MFG عام ٢٠٠٩، وهي شركة متخصصة في تشكيل المعادن، وتقع في مقاطعة جيانغسو، الصين. تقدم الشركة العديد من خدمات التصنيع، تشكيل من بين الأفضل. نقدم لكم حلولاً شاملة. نعم، من التصميم الأولي إلى صناعة القوالب، إلى التصنيع، إلى التشطيب، والفحص، نقدم لكم كل ذلك تحت سقف واحد. وهذا ما يميز HDC MFG في مجال التصنيع.

نحن نخدم العملاء من جميع أنحاء العالم، من مختلف الصناعات، مثل صناعة السيارات، والفضاء، والمنتجات الاستهلاكية، وغيرها.

قدرات التشكيل والتصنيع

- نحن نعمل مع مجموعة واسعة من المواد، مثل سبائك الألومنيوم، والصلب، وما إلى ذلك.

- نحن نقدم أنواعًا مختلفة من التشكيل، مثل التشكيل باللفائف، التشكيل بالحرارة، التشكيل بالقالب المغلق، والتشكيلات المخصصة الأخرى.

- لدينا مكابس تتراوح سعتها بين 160 طنًا إلى 4000 طن، لذلك لا داعي للقلق، حيث يمكننا التعامل مع الأجزاء ذات الحجم الكبير بشكل جيد للغاية.

- نقدم أيضًا خدمات ما بعد التشكيل، مثل المعالجة الحرارية وتشطيب الأسطح. كما نقدم خدمات التشغيل الآلي باستخدام الحاسب الآلي (الخراطة، الطحن، الحفر، إلخ).

الشهادات والمعايير

- حصلت شركة HDC على شهادة IATF 16949، وISO 9001، وISO 14001، وISO 45001.

- نحن نستخدم أيضًا معدات التفتيش، مثل أجهزة قياس الطيف، وأجهزة اختبار الشد والصلابة، وآلات قياس الإحداثيات، وآلات قياس الصلابة.

لذا، يُنصح بشدة بالاستعانة بشركة HDC MFG إذا كنت ترغب في خدمات التشكيل لمشروعك. وإذا كنت ترغب في أي خدمة تصنيع أخرى، فشركة HDC متاحة دائمًا. اتصل بنا الآن!

اكتشف المزيد مع منشورات مدونتنا.

المشاركات الاخيرة

اكتشف المزيد عن منتجاتنا

منتجات HDC

اقتباس فوري!