Precipitation Hardening Stainless Steel Explained: Grades, Uses and Benefits

- بواسطة: HDCMFG

PH Stainless Steel Quick-View

- What it is: A high-strength alloy that bridges the gap between 300-series (corrosion) and martensitic (strength)

- How to Hardening: Gains extreme hardness via Aging heat treatment after machining.

- Common Grades: 17-4 PH, 15-5 PH, 13-8 PH, 17-7 PH

- Key Benefit: Excellent dimensional stability; parts won’t distort during the final hardening process.

- Manufacturing Tips: Always machine in Solution Treated condition to reduce tool wear and costs.

✅ Technical Content Verified by HDC Engineers

Stainless steel is the material of choice when you are in need of a strong, long-lasting and noncorrosive metal. Stainless steels are, however, not all the same Others are designed to endure additional stress, additional loads and harsh labor. Precipitation hardening stainless steel is one such special type that is very effective in doing this.

This guide will teach you the meaning of precipitation hardening stainless steel, its mechanism of operation, its applications and the grade to use.

1. What is Precipitation Hardening Stainless Steel?

Precipitation hardening stainless steel, also known as PH stainless steel, is a specialized form of stainless steel, which obtains strength through heating. Rather than remaining at a single fixed level of strength, this level can be used to regulate the hardness and the strength of the steel by modifying the heat cooling cycles.

It begins with a pliable and softer material. Once it has been shaped or machined you heat treat it. In this process, the strength is locked on the steel without altering its shape.

How it Differs from Other Stainless Steel Types

PH stainless steel is different in three main aspects which are:

- Strength can be gained following fabrication.

- You have great strength plus good anti-corrosion.

- You are dimensionally stable ad heat treated.

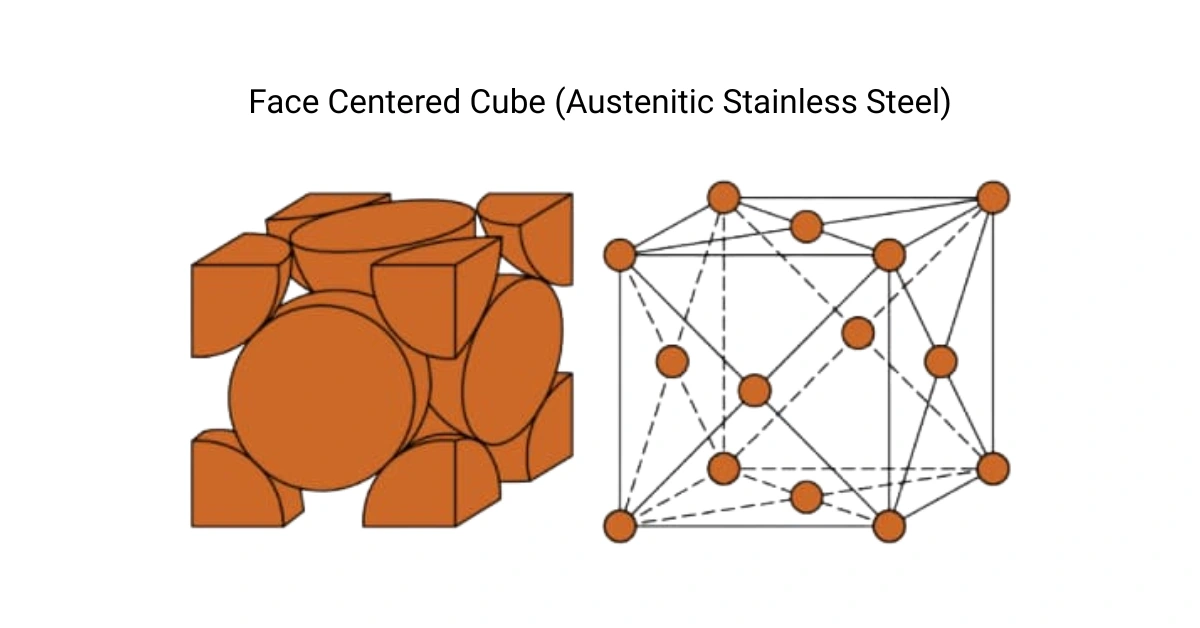

Austenitic stainless steels such as 304 have high resistance to corrosion and are not high strength. The martensitic stainless steels are strong but not as resistant to corrosion. PH stainless steel provides you with a trade-off between the two.

2. How Precipitation Hardening Stainless Steel Works

During a controlled heat treatment, PH stainless steel is becoming stronger. This generates small particles within the metal structure which do not allow movement and become harder.

Heat Treatment Process Explained

The heat treatment process consists of two major steps:

- حل

- Aging (Precipitation Hardening).

Solution treatment is done by heating the steel to a high temperature. This is done to prevent alloying elements from being evenly distributed within the metal. Once cooled the steel is soft and easy to machine.

Aging and Strengthening Mechanism

As you get older, you recycle the steel at a lower temperature. The steps make fine particles develop within the metal structure. These particles prevent internal movement and make it stronger.

Hardness is produced by control of aging temperature and time. The reduced temperatures produce greater strength. Better toughness and corrosion resistance are enhanced by increased temperature.

3. Key Properties of Precipitation Hardening Stainless Steel

PH stainless is a combination of various convenient properties that make this material appropriate to be used in demanding and high-stress applications. These properties enable you to employ the material at a time when strength, reliability and corrosion resistance are important at the same time.

High Strength and Hardness

PH stainless steel provides extremely high heat treatment tensile and yield strength. Aging enables the metal to attain strength levels comparable to those of high alloy steels without losing the stainless steel advantages. Hardness can be adjusted by modifying the aging temperature and this means that you have control of performance depending on the various loads.

مقاومة التآكل

The vast majority of PH grades are more resistant to corrosion than martensitic stainless steel and can work effectively in numerous real-life settings. They are not quick to sustain damage on surfaces due to moisture, slight chemicals and salt. This balance renders PH stainless steel a potent selection of industrial, marine and outdoor parts.

Toughness and Durability

PH stainless steel has toughness even when it is highly strong. This is a combination that makes parts resistant to cracking, impact damage and reputation stress. PH stainless steel components are more resistant to vibration and cyclic loading and this increases service life and safety.

4. Types of Precipitation Hardening Stainless Steel

Manufacturers have identified three major groups of PH stainless steel according to the microstructure. The types are used in various strength, corrosion and fabrication requirements

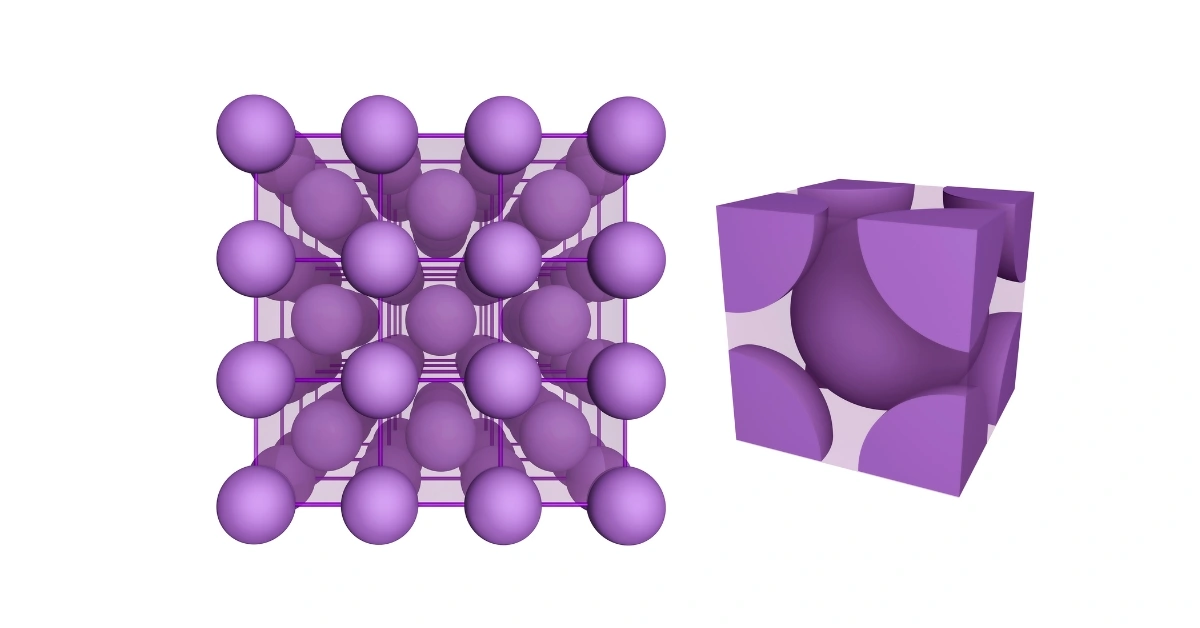

Martensitic PH Stainless Steel

This king offers the greatest strength of PH stainless steels. It is appropriate in aerospace, military and high-load mechanical components that are exposed to extreme loading. Martensitic PH stainless steel is not very strong in terms of corrosion resistance and is suited to regulated or milder surrounding conditions.

Semi-Austenitic PH Stainless Steel

This form begins as austenitic and it changes in the process of heat treatment. It is easily formable and machinable and then aged. Once heat treated it provides high strength and good toughness and is therefore suitable for complex shapes and precision components.

Austenitic PH Stainless Steel

This king has good corrosion resistance as well as strength. It has good performance in chemical work, marine and applications where corrosion resistance is more important than peak hardness.

The types are meant to accomplish different functions depending on the required strength, exposure to corrosion and forming requirements.

5. Common Grades of Precipitation-Hardening Stainless Steel

17-4 PH الفولاذ المقاوم للصدأ

The most popular Precipitation hardening stainless steel grade is 17-4 PH. It provides a very good combination of strength, corrosion resistance and heat treatment ease.

You often see this grade in:

- Aerospace components

- Valves and fittings

- Oil and gas equipment

It also machines well in solution-treated condition.

15-5 PH الفولاذ المقاوم للصدأ

The toughness and transverse strength of 15-5 PH are better than 17-4 PH. It is applicable to pressure vessels, aircraft structures, and those components that are exposed to directional loads. It is also a grade that offers enhanced uniformity in large areas.

13-8 PH Stainless Steel

13-8 PH provides extremely high strength, high toughness and fatigue resistance. It is commonly selected by engineers in aerospace fittings, shafts, and high-stress components in which failure is not possible.

17-7 PH Stainless Steel

Before heat treatment 17-7 PH is capable of good formability and is therefore easy to shape into thin or complicated parts. It is compatible with springs, fasteners, clips and lightweight structural parts, which need to have the ability to bend prior to aging.

Comparison Table of Major PH Stainless Steel Grades

| درجة | قوة | مقاومة التآكل | الاستخدامات الشائعة |

| 17-4 درجة مئوية | عالية جدًا | جيد | Aerospace, Valves |

| 15-5 PH | عالي | جيد | Aircraft Parts |

| 13-8 PH | عالية جداً | جيد جدًا | Defense, Aviation |

| 17-7 PH | واسطة | جيد | Springs, Clips |

6. Chemical Composition of PH Stainless Steel

PH stainless steel has well-thought-out components that determine the degree of strength, toughness and corrosion resistance of the steel. Any slight variation in these factors may modify the performance of the steel.

Role of Chromium, Nickel, Copper and Aluminum

- Chromium enhances resistance to corrosion and secures against rust of the surface.

- Nickel makes the structure more stable and enhances toughness and ductility.

- Copper aids the hardening of the process of precipitation and enhances strength.

- Aluminum assists in producing fine strengthening particles in the process of aging.

How Composition Affects Performance

Minor alterations in the alloy composition influence the strength, corrosion resistance and aging behavior. Increasing amounts of copper or aluminum enhance resistance post heat treatment, whereas chromium and nickel enhance environmental resistance. Every PH grade has a well-balanced mixture to achieve desired mechanical and industrial performance objectives.

7. Heat Treatment Conditions and Designations

The behavior of precipitation-hardening stainless steel is regulated by المعالجة الحرارية. In this way, you can decide on the appropriate proportion of strength and toughness.

معالجة المحلول

The treatment of solutions involves heating the steel to a high temperature during solution treatment. In this step all the strengthening elements are dissolved into the metal. The steel is soft, flexible and easy to machine after cooling.

Cutting, drilling and shaping are generally done at this step.

Aging Conditions (H900, H1025, H1150)

Aging strength is enhanced after solution treatment.

- H900: This is the condition that will provide maximum strength and hardness. It is efficient in components that are in high load.

- H1025: This is a state of moderation between strength and toughness. It is used in many industries that have safety-critical components.

- H1150: This is a condition that enhances toughness and resistance to corrosion. It is fitting for stressful and vibrant environments.

Effect of Heat Treatment on Strength

Reduced temperatures of aging result in increased hardness and strength. Increase in aging temperatures decreases strength and enhances toughness and flexibility. This is a control that assists you in matching the steel with the particular application.

8. Benefits of Precipitation Hardening Stainless Steel

Strength-to-Weight Advantage

Precipitation hardening stainless steel provides extremely high strength without any additional weight. This advantage allows you to develop light parts without the loss of functionality.

Improved Fatigue Resistance

The steel handles were less prone to frequent loading and vibration in comparison to most other metals. This resistance is beneficial in machine and vehicle life.

Dimensional Stability

PH stainless steel does not change shape when heating up. This consistency facilitates accuracy for parts to fit and to fit well within tight tolerances.

9. Industrial Applications and Uses of PH Stainless Steel

PH stainless steel is applicable in numerous industries that require strength, accuracy and dependability.

Aerospace and Aviation Components

The aircraft components require strength, low weight, and safety. PH stainless steel satisfies all three conditions. Its application to engineers is in landing gear components, fasteners, and structural components.

Oil and Gas Industry

PH stainless steel is used effectively in the valves, pumps, and components of pressure that are subjected to high pressure and hostile conditions. It is strong and corrosion and wear resistant.

Medical and Surgical Tools

Medical equipment must be strong, durable, and dependable. PH stainless steel is effective since it does not corrode and retains its shape after repeated usage.

Automotive and Industrial Machinery

PH stainless steel finds application in the automotive systems as التروس, shafts, fasteners and high-load components. It is being used in industrial machines in components where constant movement and stress are being experienced.

Marine and Chemical Environments

PH stainless steel is more resistant to salt water and other light chemicals than many others. It is commonly used in marine equipment and also in chemical processing systems.

10. Precipitation Hardening Stainless Steel vs Other Stainless Steels

PH vs Austenitic Stainless Steel

Austenitic stainless steel has a very good corrosion ability but has low strength. PH stainless steel even offers greater strength and yet remains corrosion resistant.

PH vs. Martensitic Stainless Steel

Martensitic stainless steel has a high level of strength and a low level of corrosion resistance. PH balances corrosion resistance, toughness and strength in stainless steel better.

PH vs Duplex Stainless Steel

Duplex stainless steel is resistant to corrosion but the strength is not as controllable. PH stainless steel allows you greater flexibility in heat treatment.

Comparison Table

| ميزة | Precipitation Hardening Stainless Steel | الفولاذ المقاوم للصدأ الأوستنيتي | الفولاذ المقاوم للصدأ المارتنسيتي | دوبلكس من الفولاذ المقاوم للصدأ |

| Strength Level | Very high & adjustable | منخفضة إلى متوسطة | عالي | متوسطة إلى عالية |

| Heat Treatment Control | Yes, strength changes with aging | No, not heat treatable | Yes, but limited | No, strength tuning |

| مقاومة التآكل | Good to very good | ممتاز | منخفضة إلى معتدلة | جيد جدًا |

| صلابة | عالي | عالية جدًا | معتدل | جيد |

| مقاومة التعب | ممتاز | معتدل | منخفضة إلى معتدلة | جيد |

| Magnetic Property | Usually magnetic | غير مغناطيسي | مغناطيسي | Partially magnetic |

| قابلية التصنيع | Good before aging | جيد | معتدل | صعب |

| Dimensional Stability | Excellent after heat treatment | جيد | معتدل | جيد |

| التطبيقات الشائعة | Aerospace, oil & gas, medical | Food, chemical kitchen | Knives, tools & shafts | Marine, chemical plants |

| المزايا الرئيسية | Strength + Corrosion balance | Best corrosion resistance | Simple high strength | Corrosion and stress resistance |

| Key Limitations | Higher cost | Lower Strength | Poor corrosion resistance | Limited strength control |

11. Machinability and Fabrication Considerations

Machining in Solution Annealed Condition

PH stainless steel should be machine aged. At this point, the metal remains tender and minimizes the wear of tools. This method is time-saving and money-saving.

Welding Challenges and Best Practices

PH stainless steel can be welded, but heat input should be regulated. Upon welding, the strength and performance are restored by means of good heat treatment.

Forming and Finishing Tips

Form the steel before aging. Once it has become old, the material becomes extremely hard and hard to form. Before final heat treatment, finishing processes are effective.

12. Corrosion Resistance and Environmental Performance

Precipitation hardening stainless steel works well in most of the environments where strength and the ability to resist corrosion are of the essence. The alloy composition is balanced, which means that it can be exposed to daily handling without degrading fast.

Performance in Harsh Environment

When you choose the right grade of stainless steel and heat treatment, PH stainless steel will resist the moisture, humidity, and mild chemicals. It is a reliable material in outdoor and marine as well as industrial applications where normal carbon steel would easily corrode. Normal operation can also tolerate many PH grades to light salt and chemical splash.

Resistance to Stress Corrosion Cracking

A vast number of PH grades have a higher resistance to stress corrosion cracking compared to martensitic stainless steel. This resistance aids parts in withstanding combined stress and corrosive exposure, particularly in pressure systems and rotating parts and components. The resistance to crack propagation with time is further enhanced by proper heat treatment.

13. Limitations of PH Stainless Steel

اعتبارات التكلفة

PH stainless steel is more expensive than normal stainless steel due to alloying elements and the heat treatment process.

Temperature Limitations

Strength may decrease with time due to high temperature. PH stainless steel can be used in moderate temperatures.

Corrosion Limits Compared to Austenitic Grades

The austenitic stainless steel continues to have better corrosive resistance in highly aggressive chemical conditions.

14. How to Choose the Right Precipitation Hardening Stainless Steel Grade

It should always be matched with the precipitation-hardening stainless steel grade with your application requirements. A good choice enhances safety and performance as well as service life.

Load and Strength Requirements

Select grade and aging condition depending on the desired level of loads and stress. Parts of high load take advantage of reduced aging temperatures, whereas mixed stress components may need a compromise of strength and toughness.

Corrosion Exposure

Before choosing a grade, examine the surroundings. Take into account the moisture, chemicals, temperature and exposure time. Correction of corrosion resistance to actual operating conditions helps to avoid premature failure.

Industry-Specific Selection Tips

13-8 PH and 15-5 PH are popular in aerospace due to their high toughness and strength. 17-4 PH is usually used in industrial and general-purpose applications since it offers a balance between performance, cost and availability.

15. Conclusion

Precipitation hardening stainless steel provides both its strength and durability and corrosion resistance in a simple material. It also enables you to make parts easily and harden them in the future without distortion. This capability enables PH stainless steel to be a prudent option for the harsh industry.

At HDC, we realize the value of selecting the appropriate material to make use of towards your project. We assist you in choosing, sourcing and putting in use precipitation-hardening stainless steel that gives long-term efficiency. In the event that you require professional service, a dependable provision or technical assistance, then call us today and have our team assist you to create stronger, smarter and safer solutions

الأسئلة الشائعة

1. What is the most common precipitation-hardening stainless steel grade?

The most popular grade is 17-4 PH as it is the best grade that balances strength and corrosion resistance.

2. Is PH stainless steel magnetic?

Yes, the PH stainless steel grades are mostly magnetic.

3. Can PH stainless steel be welded?

Yes, however, it does make a difference when welding is properly heated.

4. Is Ph stainless steel stronger than 304 stainless steel?

Yes, PH stainless steel is much stronger than 304 stainless steel post heat treatment.

5. Can precipitation-hardening stainless steel be welded?

Yes, it can be welded, however, it is important that it be heat treated after welding.

6. Does PH stainless steel rust?

It is also very resistant to rust and yet severe environments may lead to corrosion in the course of time.

اكتشف المزيد مع منشورات مدونتنا.

المشاركات الاخيرة

اكتشف المزيد عن منتجاتنا

المنتجات المخصصة

عرض سعر فوري مجاني!