Unlocking the Potential of OEM CNC Machining Services for Precision Manufacturing

Discover the essential advantages of OEM CNC Machining Services in precision manufacturing, from enhancing accuracy and reducing costs to enabling complex designs and ensuring consistent quality. Learn about the standard processes, industries benefiting from these services, the diverse machining techniques used, and key materials involved. Understand the cost considerations and how to choose the right OEM CNC machining partner for your needs.

Meaning of OEM

OEM, an acronym for Original Equipment Manufacturer, refers to companies that design and produce components or products that are then sold and used by another company. In this context, the manufacturer creating the original product is referred to as the OEM. These components or products are often integrated into the end product of the second company, which sells the final product under its own brand name. OEMs play a crucial role in the supply chain, providing specialized parts or equipment to various industries without directly marketing the final product to end consumers. The term underscores the distinction between the company that produces the original equipment and the one that incorporates it into a finished product for distribution and sale.

Advantages of OEM CNC Machining Service

- Precision Excellence: Leveraging CNC technology, OEM CNC machining ensures meticulous accuracy, meeting exact specifications for components.

- Cost-Efficiency: Outsourcing to OEM services provides cost savings, as economies of scale allow for high-precision manufacturing without a hefty price tag.

- Streamlined Production: Automation in CNC machining minimizes errors, contributing to a more efficient and streamlined production process.

- Material Versatility: CNC machining accommodates a diverse range of materials, from metals to plastics and advanced composites, offering flexibility to meet various industry needs.

- Complex Designs Made Feasible: CNC machining excels in bringing intricate designs to life, pushing the boundaries of what’s achievable in manufacturing.

- Consistency in Quality: Automated precision ensures consistent and high-quality manufacturing, crucial for industries prioritizing product performance and safety.

- قابلية التوسع: OEM CNC machining services are adaptable to both small and large production volumes, providing flexibility to meet varying demand scales.

- Reduction in Lead Times: Efficiency in CNC machining leads to faster production, reducing lead times and accelerating time-to-market for manufactured components.

Standard Process of OEM CNC Machining Service

The standard process of OEM CNC Machining Service follows a systematic and precise approach, ensuring the production of high-quality components. Let’s break down the key stages of this process:

- Design Analysis: Thoroughly analyze component design requirements.

- Computer-Aided Design (CAD): Translate the design into a digital format using CAD software.

- اختيار المواد: Choose the appropriate material based on design and application.

- التصنيع باستخدام الحاسب الآلي: Utilize CNC technology to precisely shape the material according to the digital design.

- ضبط الجودة: Implement regular checks to ensure components meet specified tolerances and quality standards.

This standardized process ensures a seamless transition from design to finished product, emphasizing precision, material suitability, and stringent quality control. The integration of CNC technology plays a pivotal role in achieving consistency and accuracy in the manufacturing of OEM components.

Industries Benefiting from OEM CNC Machining

OEM CNC Machining proves indispensable across diverse industries. In aerospace, it ensures the precision of critical components for aircraft safety. Automotive manufacturers rely on it for enhanced vehicle performance, while the medical field benefits from intricate and customized components for devices. The electronics industry utilizes OEM CNC machining to manufacture precise components for electronic devices, ensuring functionality and reliability. In essence, this advanced machining service is a linchpin for precision manufacturing across technology, transportation, healthcare, and electronics sectors.

CNC Machining Techniques Offered by OEM CNC Machining Service

OEM CNC Machining Services provide a range of advanced techniques to meet the diverse needs of precision manufacturing. Here are some key CNC machining techniques offered by these services:

- الطحن:

- This technique involves the removal of material using rotary cutters. It is ideal for creating complex shapes and features.

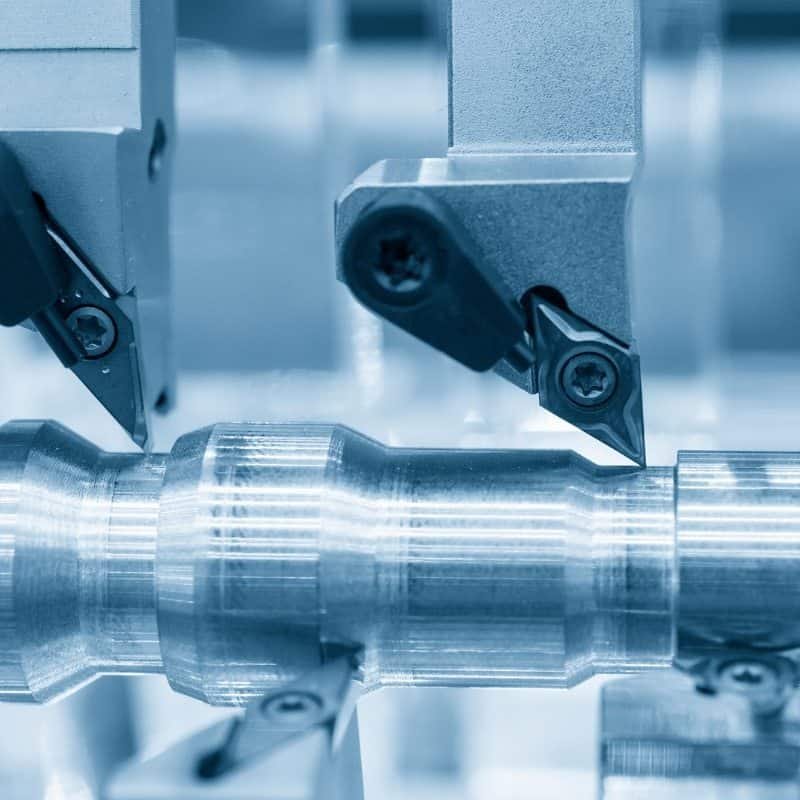

- تحول:

- Turning utilizes a lathe to rotate the workpiece, allowing for precision cutting. It is commonly used for cylindrical components.

- Drilling:

- As the name suggests, drilling involves creating holes in the workpiece. CNC drilling ensures accuracy and consistency in hole placement.

- المعالجة بالتفريغ الكهربائي (EDM):

- EDM utilizes electrical discharges for shaping the workpiece. It is effective for intricate and detailed components, especially in harder materials.

These techniques, guided by computer-controlled precision, allow OEM CNC Machining Services to cater to a wide range of manufacturing requirements, from simple to highly intricate components.

Materials Used for CNC Machining

OEM CNC Machining Services operate with versatility in mind, accommodating various materials to meet the demands of precision manufacturing. Here are key materials commonly used in CNC machining:

Cost Consideration for OEM CNC Machining Service

OEM CNC Machining Services entail key cost considerations. Material choices, spanning metals, plastics, and composites, significantly impact overall expenses. The machining time required, especially for intricate designs, influences costs, as does the complexity of the design itself. Striking a balance between material selection, machining time, and design intricacy is essential for clients seeking cost-effective yet precise manufacturing solutions.

Choose The Right OEM CNC Machining Service

Selecting the right OEM CNC Machining Service is a critical decision for optimal precision manufacturing. Consider the following factors to ensure a seamless partnership:

- Experience and Expertise:

- Assess the service provider’s experience in CNC machining and their expertise in handling projects similar to yours. A track record of successful and diverse projects speaks volumes about their capabilities.

- Technology and Infrastructure:

- Ensure the service has up-to-date CNC technology and a robust infrastructure. The integration of advanced machinery enhances the precision and efficiency of the machining process.

- ضمان الجودة:

- A strong emphasis on quality assurance is paramount. Look for services with rigorous quality control measures to guarantee the accuracy and reliability of the manufactured components.

Making an informed decision based on these considerations ensures a partnership with an OEM CNC Machining Service that aligns with your specific manufacturing needs and quality standards.

خاتمة

In the intricate dance of precision and production, OEM CNC machining emerges as the virtuoso. Its advantages, coupled with a streamlined process and diverse applications, make it an indispensable ally for industries seeking perfection in every component.