يعتبر الفولاذ 4130 ولا يزال أحد أكثر أنواع الفولاذ شيوعًا في العديد من الصناعات. ولكن لماذا؟ ما الذي يجعل الفولاذ 4130 خيارًا أفضل من أنواع الفولاذ الأخرى؟ ما الذي يفتقر إليه الفولاذ 4130؟

في هذه المدونة، سنتناول كل ما تحتاج إلى معرفته حول 4130، وكيفية مقارنته بأنواع الفولاذ الأخرى، وأين يتم استخدامه، والمزيد!

اقرأ المزيد: دليل شامل لختم المعادن

ما هو الفولاذ 4130؟

الفولاذ 4130 هو نوع معين من الفولاذ يشار إليه غالبًا باسم كروموليوهو عبارة عن فولاذ منخفض السبائك مصنوع من الموليبدينوم والكروم مع محتوى كربون يبلغ حوالي 0.3%.

من بين السبائك المعدنية المختلفة يعتبر 4130 أحد الفولاذ الأكثر شعبية ومطلوبًا أنواع بسبب قوتها وقدرتها على التحمل.

ما هي فوائده؟

لا توجد بيانات واضحة عنه، ولكن تم اكتشافه في أواخر القرن التاسع عشر أو أوائل القرن العشرين. وقد تم تصنيعه في الأصل ليكون مكونًا في صناعة الطيران لأنه قوي وخفيف الوزن في نفس الوقت.

وبعد مرور بضع سنوات، ظهر الفولاذ كعنصر مفيد في مركبات وآلات السباق، مثل سيارة SCCA، وسيارات الفورمولا 1، وسيارات الدراجستر، وما إلى ذلك.

اليوم، تستخدم العديد من الشركات مادة 4130 في مجموعة متنوعة من التطبيقات. بدءًا من تطبيقاتها الأصلية في مجال الطيران والسيارات إلى أدوات الآلات والهيدروليكا والمعدات الرياضية، فهي واسعة النطاق ومتعددة الاستخدامات ومرنة.

اقرأ المزيد: الألومنيوم مقابل التيتانيوم

4130 خصائص الفولاذ وتطبيقاته

دعنا نتعمق في خصائص ومواصفات الفولاذ 4130 حتى تعرف ما الذي ستواجهه! إن فهم هذا الأمر يعد طريقة رائعة لمعرفة ما إذا كان هذا الفولاذ هو ما تبحث عنه حقًا.

خصائص الفولاذ 4130

القوة الميكانيكية

أولاً وقبل كل شيء، ما مدى قوتها حقًا؟ يُعد الفولاذ 4130 من الفولاذ منخفض السبائك المعروف بنسبة القوة إلى الوزن الممتازة.

فهو يتميز بقوة شد عالية، مما يجعله قادرًا على تحمل الأحمال الثقيلة مع الحفاظ على وزنه الخفيف.

بالإضافة إلى ذلك، فهو يوفر صلابة جيدة ومقاومة للتعب، مما يضمن المتانة حتى في البيئات الصعبة.

مقاومة الحرارة

إذا كان هناك شيء واحد تتميز به هذه الفولاذ والسبائك، فهو مقاومة الحرارة. يعمل الفولاذ 4130 جيدًا في درجات الحرارة المرتفعة، ويحافظ على سلامته البنيوية وخصائصه الميكانيكية.

إن مقاومتها للحرارة تجعلها خيارًا موثوقًا به للتطبيقات التي يكون فيها التعرض لدرجات الحرارة المرتفعة أمرًا لا مفر منه، مثل محركات الطائرات أو الآلات الصناعية.

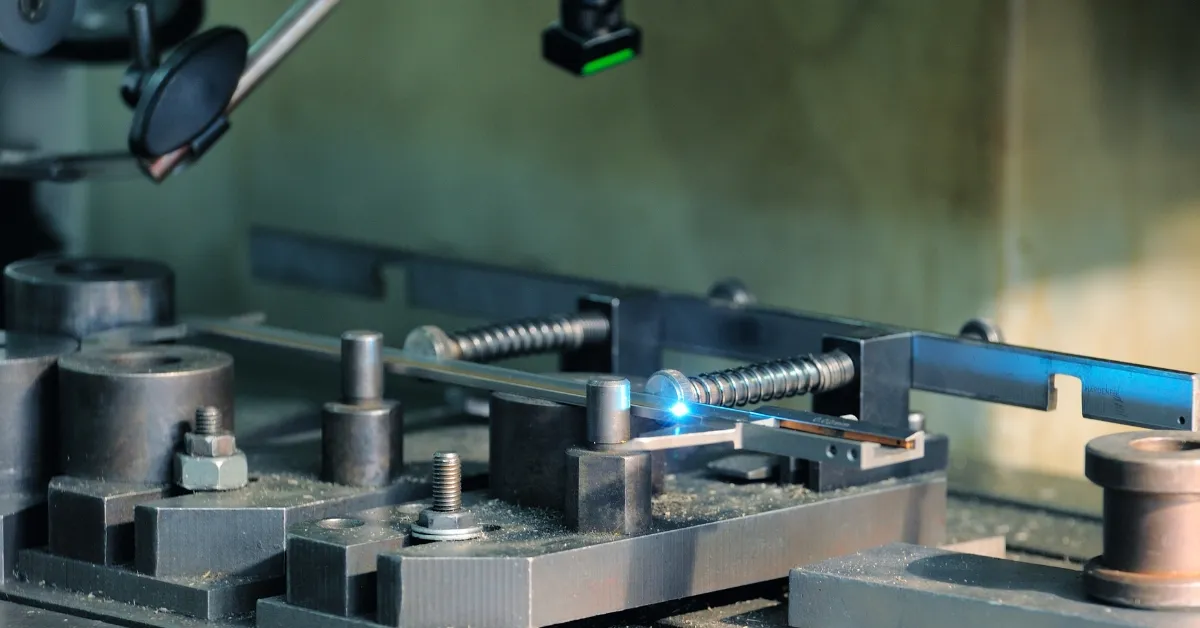

قابلية اللحام والتشغيل الآلي

من أهم مميزات الفولاذ 4130 هو قابليته الاستثنائية للتلحيم، مما يتيح التوصيل السلس دون التضحية بالقوة. يمكن لحامو المعادن الاستمتاع بأي شيء بدءًا من اللحام بالقوس، وGMAW، وGTAW، واللحام، وغير ذلك الكثير!

إن قابليتها الجيدة للتصنيع تسمح لها بإجراء عمليات قطع وتشكيل وحفر دقيقة، مما يجعلها المفضلة للتصميمات المخصصة والمعقدة.

مقاومة التآكل والتآكل

لا تخلط بين الأمرين. فالمعدن 4130 ليس ممتازًا بطبيعته في مقاومة المواد الكيميائية. نعم، فهو مقاوم للتآكل والمواد الكيميائية، ولكن إلى حد ما فقط. وهناك معالجات معروفة مثل الجلفنة أو طلاء الكروم تساعد في تعزيز خصائصه الوقائية.

ملحوظة: ويتميز بمقاومة معتدلة للتآكل، وخاصة بعد المعالجة الحرارية المناسبة، مما يجعله مناسبًا للمكونات المعرضة للاحتكاك أو التآكل.

مقاومة التأثير

وأخيرًا وليس آخرًا، فإن مقاومة الصدمات هي ما يميز الفولاذ 4130. فحتى في درجات الحرارة المنخفضة، يحتفظ الفولاذ 4130 بمقاومة مذهلة للصدمات، مما يقلل من خطر الفشل المفاجئ.

تجعل هذه الخاصية المنتج قيماً للبيئات التي تكون فيها القوى غير المتوقعة أو التأثيرات أو الصدمات شائعة ومعتادة.

تطبيقات الفولاذ 4130

الفضاء والسيارات

إن القوة ومقاومة الحرارة وخفة الوزن التي يتمتع بها الفولاذ 4130 تجعله لا غنى عنه في قطاعي الطيران والسيارات. يتم استخدامه في هياكل الطائرات والأقفاص الدوارة والهياكل، مما يضمن السلامة والأداء.

معدات النفط والغاز

في صناعة الطاقة، يتم استخدام الفولاذ 4130 في أدوات الحفر وخطوط الأنابيب ومكونات الحفارات، وذلك بفضل قدرته على تحمل الضغط والإجهاد.

الدراجات الهوائية والمعدات الرياضية

إن الجمع بين المرونة والقوة وخفة الوزن يجعله مادة مفضلة للدراجات عالية الأداء والعتاد الرياضي.

البناء والآلات الثقيلة

تستخدم صناعات البناء الفولاذ 4130 في أجزاء الآلات ومكونات الرافعات والأطر الهيكلية، مستفيدة من متانته وقدرته على التكيف.

إن الخصائص الفريدة وتعدد استخدامات الفولاذ 4130 تضمن استخدامه على نطاق واسع في جميع الصناعات التي تتطلب الأداء والموثوقية والقدرة على التكيف.

اقرأ المزيد: هل الألومنيوم موصل للكهرباء

أسعار وتوافر الفولاذ 4130

يختلف سعر الفولاذ 4130 حسب الطلب في السوق والمورد وحجم الطلب. وقد تتراوح الأسعار من $1.50 إلى $3.50 للرطل الواحد من المواد الخام، مع تكاليف إضافية للمعالجة مثل القطع أو المعالجة الحرارية أو التشكيل.

ملحوظة: إذا كنت تريد توفير المال وإذا كنت بحاجة إلى أكثر من بضع مئات من المنتجات، فاستخدم الطلبات بالجملة أو بالجملة. غالبًا ما تؤدي الطلبات بالجملة إلى أسعار أفضل، في حين أن الدرجات أو الأحجام المتخصصة قد تزيد التكاليف.

من حيث التوافر، فهو متوفر على نطاق واسع ويحظى بشعبية كبيرة. ويُستخدم في العديد من الصناعات المختلفة ويمكن الحصول عليه من العديد من المواقع المختلفة.

تعتمد التسعير الدقيق والتوافر على عوامل الوقت الفعلي، لذا فإن التواصل مع الموردين للحصول على عروض الأسعار يظل النهج الأفضل.

هل الفولاذ 4130 قابل للانحناء؟

نعم، يمكن ثني 4130، ولكن انتبه إلى أن مستويات القوة العالية التي يتمتعون بها تسمح لهم بالانحناء بسهولة. إذا تم ذلك بشكل غير صحيح، فقد يصبح 4130 هشًا وينكسر دون داعٍ، لذا، يلزم اتخاذ التدابير الاحترازية الصحيحة.

تأكد من أنك تترك للمحترفين التعامل مع ثني الفولاذ 4130 وتقويسه للتأكد من أنه لن ينكسر إلى نصفين بسهولة.

هل يمكن تقوية الفولاذ 4130؟

نعم، من الممكن تقوية وتعزيز مستوى صلابة الفولاذ 4130. ويمكن القيام بذلك من خلال عملية التلطيف، ويجب أن تكون درجة الحرارة حوالي 1600 درجة فهرنهايت أو 870 درجة مئوية.

ملحوظة: ومع ذلك، من المهم أن تأخذ بعين الاعتبار قوة الخضوع للفولاذ 4130 لتجنب إتلافه. تذكر أنه ليس قابلاً للانحناء مثل الأنواع الأخرى من السبائك والمعادن، لذا من المهم أن تكون حذرًا عند التخطيط لتصلبه أو إخماده.

لماذا يعد HDC أفضل مصدر للفولاذ 4130 عالي الجودة؟

في HDC، نحن متخصصون في تصنيع أجزاء معدنية مخصصة عالية الجودة، بما في ذلك المكونات الدقيقة المصنوعة من الفولاذ 4130 ومواد متقدمة أخرى. ورغم أننا لسنا شركة مصنعة للمواد، فإن خبرتنا تكمن في تحويل المواد عالية الجودة مثل الفولاذ 4130 إلى منتجات نهائية استثنائية مصممة خصيصًا لتلبية احتياجاتك.

منذ تأسيسنا، بنينا سمعة طيبة في التميز في العمل مع مجموعة واسعة من المعادن والسبائك - من الفولاذ المقاوم للصدأ و الفولاذ الكربوني ل سبائك النيكل و سبائك التيتانيوميتمتع فريقنا بالمعرفة والموارد لمساعدتك في اختيار المادة والتصميم المناسبين لمشروعك.

اكتشف المزيد مع منشورات مدونتنا.

المشاركات الاخيرة

اكتشف المزيد عن منتجاتنا

منتجات HDC

اقتباس فوري!