سبائك النيكل هي جزء من مجموعة السبائك الأكثر شيوعًا، والتي تُستخدم عادةً في المزيد من التطبيقات. ستتناول هذه المدونة فهم سبائك النيكل بشكل أكبر، من خصائصها واستخداماتها إلى كيفية إعادة تشكيل التصنيع في المستقبل، بدءًا من عام 2025.

اجلس واسترخي وتأكد من عدم تفويت أي معلومات حول سبائك النيكل!

ما هي سبائك النيكل؟

- الألومنيوم

- الكروم

- حديد

- الموليبدينوم

- النيكل (أكبر الكميات)

- عناصر أخرى بنسب صغيرة

إيجابيات وسلبيات سبائك النيكل

الآن، دعنا ننتقل إلى تحديد مزايا وعيوب هذه السبائك القائمة على النيكل. إن معرفة وفهم هذا الأمر مهم لأنه يسمح لك بمعرفة ما إذا كانت مناسبة لشركتك أم لا.

مزايا السبائك القائمة على النيكل

توفر السبائك القائمة على النيكل العديد من المزايا البارزة التي تجعلها لا غنى عنها في التطبيقات الصناعية المختلفة. وتشمل هذه المزايا:

مقاومة استثنائية للتآكل

تتميز السبائك القائمة على النيكل بقدرتها على مقاومة التآكل في البيئات القاسية. ويمكن لهذه المواد أن تتحمل التعرض للمواد الكيميائية العدوانية مثل الأحماض القوية والقلويات وحتى مياه البحر، مما يجعلها لا غنى عنها في الصناعات مثل النفط والغاز.

تضمن مرونتها عمرًا أطول للمكونات، مما يقلل من تكاليف الصيانة ووقت التوقف عن العمل.

الخصائص المغناطيسية المميزة

تتمتع بعض سبائك النيكل، وخاصة تلك التي تحتوي على نيكل 72-83%، بخصائص مغناطيسية ممتازة. وهذا يجعلها مثالية للاستخدام في المحولات والمحثات والدروع المغناطيسية.

إن قدرتها على الحفاظ على الأداء المغناطيسي على مر الزمن تضمن الأداء المتسق للمكونات الكهربائية والإلكترونية الحيوية.

اقرأ المزيد: دليل شامل لختم المعادن

طول العمر وكفاءة التكلفة

تعترض العديد من الشركات على التكاليف الأولية المرتفعة لسبائك النيكل. على الرغم من ذلك، توفر سبائك النيكل قيمة استثنائية من خلال تقليل تكرار الإصلاحات والاستبدالات.

إن متانتها ومقاومتها للتآكل توفر وفورات طويلة الأجل، مما يجعلها خيارًا ذكيًا للصناعات التي تركز على الموثوقية والفعالية من حيث التكلفة. في اللعبة طويلة الأجل، تعمل سبائك النيكل كالسحر، حيث يتحسن أداؤها بمرور الوقت.

أداء فائق في درجات الحرارة العالية

تشتهر سبائك النيكل بثباتها الحراري المذهل، حيث تحتفظ بقوتها حتى في ظل الحرارة الشديدة. وهذه الخاصية ضرورية للتطبيقات في مجال الفضاء وتوليد الطاقة، حيث يجب أن تتحمل المواد درجات الحرارة القصوى دون فقدان سلامتها البنيوية.

وتجعلها هذه المتانة خيارًا موثوقًا به للتوربينات والمحركات النفاثة وغيرها من الأنظمة عالية الأداء.

خصائص ميكانيكية ممتازة

تتمتع سبائك النيكل بالقدرة على تحمل قدر كبير من الضغط والتشوه دون أن تنكسر أو تتشقق بسبب قوتها العالية على الشد ومرونتها الجيدة.

هذه الخصائص تجعلها مثالية للتطبيقات الصعبة مثل صناعات البناء والسيارات حيث تكون القوة والموثوقية ضرورية.

هذه ليست سوى بعض المزايا الرئيسية والأساسية لسبائك النيكل. هناك المزيد بالطبع، ولكن مثل أي شيء آخر، هناك أيضًا سلبيات وعيوب. وتشمل هذه السلبيات:

عيوب السبائك القائمة على النيكل

لا تتسم سبائك النيكل بالتنوع والتعدد. ومن ناحية أخرى، هناك سلبيات وعيوب سبائك النيكل. إليك هذه السلبيات والعيوب حتى تعرف ما الذي تحتاج إلى إعادة النظر فيه.

ارتفاع التكلفة والاستثمار

من بين العيوب الكبيرة لسبائك النيكل ارتفاع تكلفتها مقارنة بالمواد الأكثر شيوعًا. وينبع هذا من ندرة النيكل والعمليات المعقدة التي تنطوي عليها عملية إنتاجه.

بالنسبة للصناعات ذات الميزانية المحدودة والشركات التي لديها نطاق وصول أصغر، يمكن أن تكون التكلفة عاملاً مقيدًا. ومع ذلك، تجدر الإشارة إلى أن هذا الاستثمار الكبير لا يتم إلا في البداية أو أثناء عملية تكوين رأس المال.

بمرور الوقت، أصبحت التكاليف المرتبطة بسبائك النيكل أفضل، وتوفر قيمة أكبر، كما أنها أكثر فعالية من حيث التكلفة واستراتيجية مقارنة بالمواد الأخرى.

اقرأ المزيد: ما هي الآلات ذات التسامح الصفري

قابلية التصنيع المحدودة

هناك عيب آخر وهو قابلية التصنيع. نظرًا لصلابة سبائك النيكل ومقاومتها للتآكل، فمن الصعب تصنيعها. فهي عادة ما تكون صلبة وقوية وأقل مرونة من نظيراتها.

تميل هذه المواد إلى التصلب أثناء التصنيع، لذا فإن التعامل معها بنجاح يتطلب استخدام أدوات وطرق معينة. وقد ترتفع مدة الإنتاج والتكاليف نتيجة لذلك.

المخاوف البيئية

يشكل استخراج خام النيكل ومعالجته مخاطر بيئية، بما في ذلك تلوث الهواء والماء. صندوق الاستثمار الأوروبي تم العثور على حالة خطيرة من تلوث الهواء والماء بالقرب من مناجم النيكل، والتي يمكن أن تلوث وتعرض الحياة حولها للخطر.

ويجب على الصناعات التي تستخدم سبائك النيكل أن تأخذ هذه التحديات البيئية في الاعتبار وتبني ممارسات مستدامة للتخفيف من تأثيرها.

صعوبات اللحام

وأخيرًا وليس آخرًا، هناك صعوبة في اللحام. فبسبب المتطلبات الفريدة لسبائك النيكل، قد يكون لحامها أمرًا صعبًا.

تتطلب اللحامات القوية وطويلة الأمد مادة حشو تتوافق تركيبتها الكيميائية مع تركيب المعدن الأساسي. إذا لم يحدث ذلك، فقد يفشل اللحام، مما يتطلب عمليات استبدال أو إصلاح باهظة الثمن.

أنواع سبائك النيكل

- سبائك النيكل والنحاس (على سبيل المثال، المونيل): تشتهر هذه السبائك بمقاومتها الممتازة للتآكل في البيئات البحرية، وتُستخدم على نطاق واسع في بناء السفن والمعدات الكيميائية والصمامات.

- سبائك النيكل والحديد (على سبيل المثال، إنفار):تتميز هذه السبائك بتمدد حراري ضئيل، مما يجعلها مثالية للأدوات الدقيقة، مثل الساعات والمعدات العلمية.

- سبائك النيكل والكروم (على سبيل المثال، Inconel):تم تصميمها للأداء في درجات الحرارة المرتفعة، وغالبًا ما تستخدم في المحركات النفاثة والتوربينات الغازية والمبادلات الحرارية.

- سبائك النيكل والموليبدينوم (على سبيل المثال، هاستيلوي):تتمتع هذه السبائك بمقاومة للمواد الكيميائية والأحماض العدوانية، وتستخدم في المعالجة الكيميائية ومحطات الطاقة.

- سبائك النيكل والتيتانيوم (على سبيل المثال، النيتينول):بفضل خصائص الذاكرة الشكلية الفريدة، تُستخدم هذه السبائك عادةً في الأجهزة الطبية مثل الدعامات وأقواس الأسنان.

- سبائك النيكل والكوبالت:تشتهر هذه المواد بقوتها العالية ومقاومتها للتآكل، وتُستخدم في مكونات الطائرات والأدوات الصناعية.

خصائص سبائك النيكل وتطبيقاتها: كل ما تحتاج إلى معرفته!

تشتهر سبائك النيكل بأدائها الاستثنائي حتى في البيئات الحرجة والصعبة. تجمع هذه المواد متعددة الاستخدامات النيكل مع عناصر أخرى، مما يعزز خصائص معينة، مما يجعلها لا غنى عنها في مختلف الصناعات.

خصائص سبائك النيكل

تحرص الشركات والمؤسسات على استخدام سبائك النيكل بسبب خصائصها وميزاتها. لذا، إليك الخصائص التي تتمتع بها سبائك النيكل والتي تجعلها تبرز في الصناعة.

صلابة عالية المستوى

الخاصية الأولى التي تتمتع بها سبائك النيكل هي مستوى صلابتها العالي. وبسبب صلابتها الاستثنائية، يمكن لسبائك النيكل أن تتحمل الكسر وتمتص الطاقة.

وبسبب هذا، يمكنك استخدامها في التطبيقات المقاومة للصدمات مثل العناصر الهيكلية وأجزاء السيارات. وفي التطبيقات الحاسمة حيث لا يكون الفشل خيارًا، تضمن متانتها الموثوقية.

مقاومة التآكل

تتمتع سبائك النيكل بمقاومة ممتازة للتآكل، حتى في البيئات القاسية. وهذا يجعلها مثالية للتطبيقات المعرضة لمياه البحر والمواد الكيميائية والرطوبة العالية.

تضمن قدرتها على تحمل الأكسدة طول العمر وتقلل من تكاليف الصيانة. كما أنها أكثر ملاءمة للميزانية بسبب مستويات مقاومتها للتآكل.

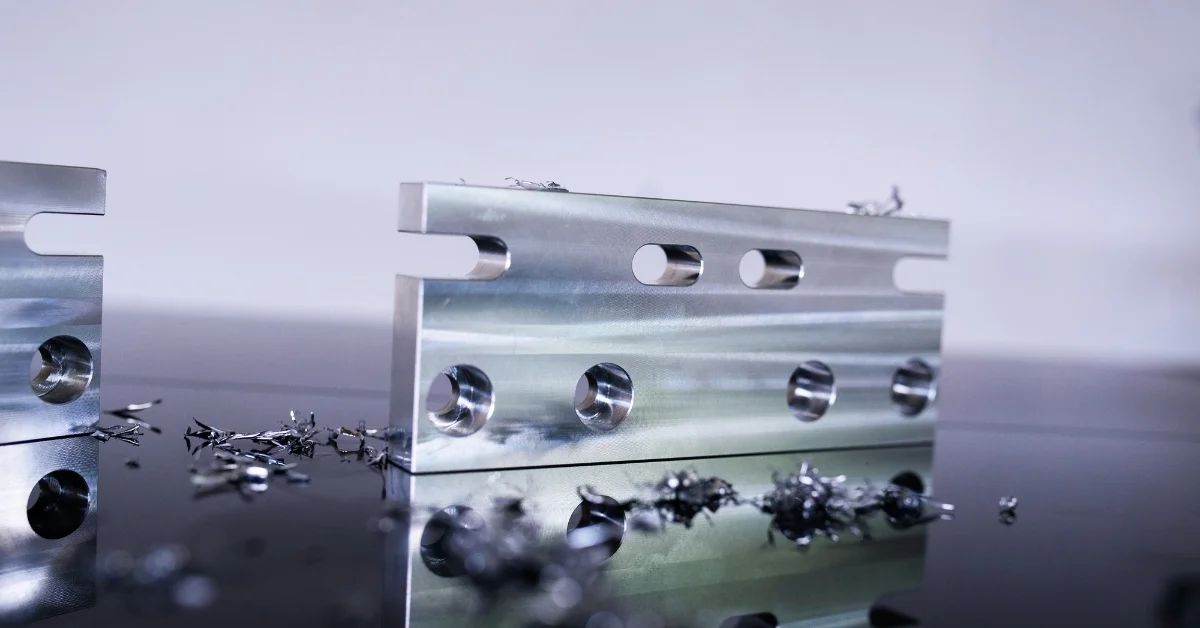

المتانة ومقاومة التآكل

في حال لم تكن تعلم، فإن هذه السبائك تمتلك أيضًا مقاومة ممتازة للتآكل، مما يجعلها مثالية للتطبيقات التي تنطوي على الاحتكاك والتآكل.

تستفيد المكونات مثل التروس والمحامل وأدوات القطع من العمر الافتراضي الممتد الذي توفره سبائك النيكل. وهذا يقلل من وقت التوقف عن العمل ويعزز الكفاءة العامة في الآلات.

مقاومة درجة الحرارة

في درجات الحرارة المرتفعة، يتم الاحتفاظ بقوة واستقرار العديد من سبائك النيكل. فهي لا تنحني أو تنكسر أو تتشقق في درجات الحرارة التي قد تتعرض لها المواد العادية.

هذه الخاصية ضرورية للأجزاء المستخدمة في الأفران الصناعية والتوربينات والمحركات. في التطبيقات ذات الحرارة العالية، تضمن قدرتها على تحمل الإجهاد الحراري الأداء الموثوق والسلامة.

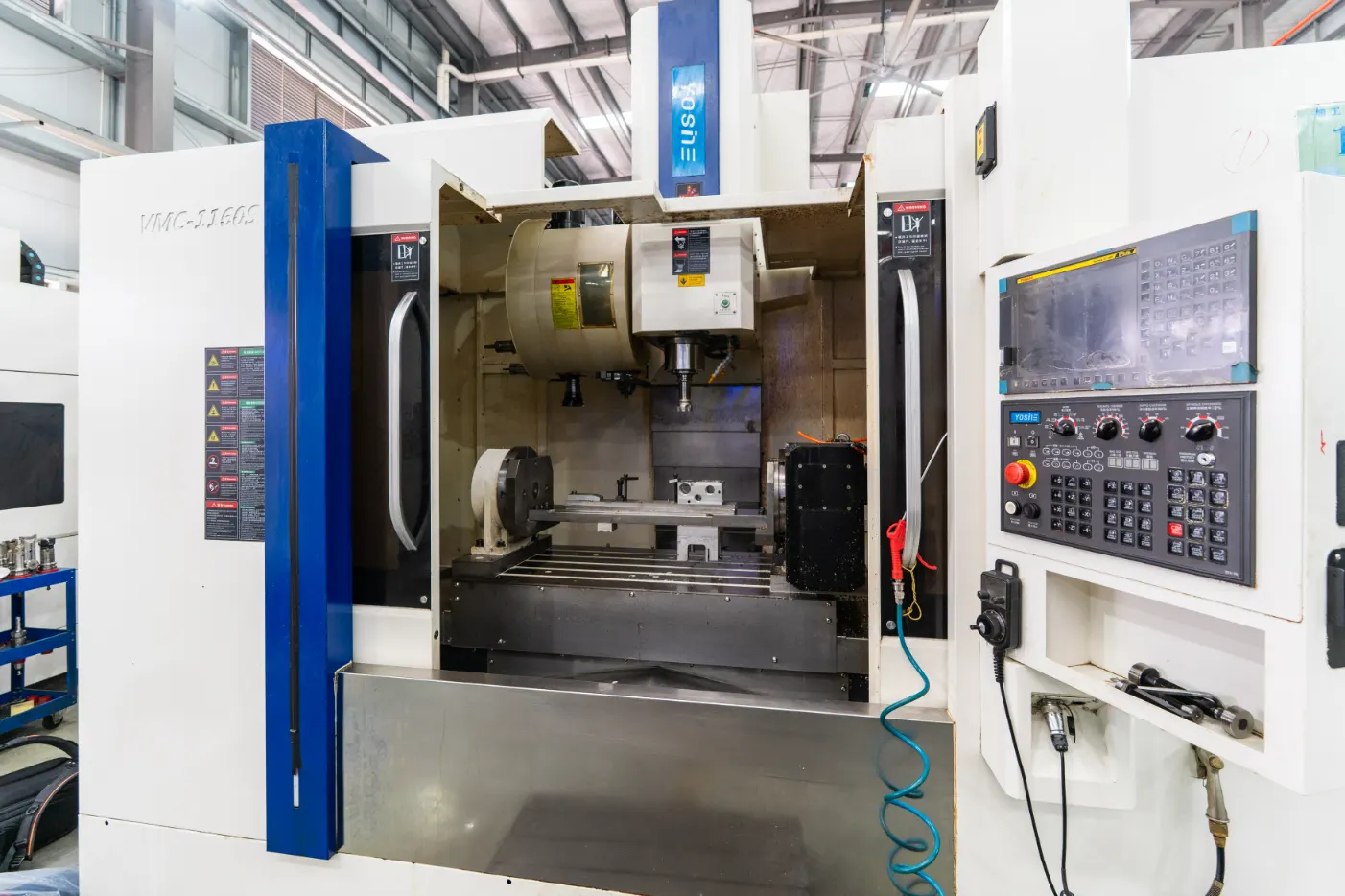

قابلية التصنيع

وأخيرًا، سهولة تصنيعها. فعلى الرغم من قوتها، يمكن تصنيع العديد من سبائك النيكل وتشكيلها بسهولة نسبية.

يتيح هذا التنوع تصنيعًا دقيقًا للأشكال المعقدة والتصميمات المعقدة. تعتمد الصناعات مثل الفضاء والإلكترونيات على هذه الخاصية لإنتاج مكونات عالية الجودة ومفصلة.

على الرغم من أنها ليست الأفضل من حيث قابلية التصنيع، إلا أنه لا يزال بإمكانك تصنيعها ومعالجتها لإنشاء مادة أو منتج جديد.

تطبيقات سبائك النيكل

- صناعة الطيران والفضاء

- تُستخدم سبائك النيكل في أجزاء المحركات والتوربينات والهياكل، مما يضمن السلامة في ظل الظروف القاسية.

- المعالجة الكيميائية

- تُستخدم سبائك النيكل في بناء المفاعلات والأنابيب، وتوفر مقاومة للتآكل في البيئات الكيميائية العدوانية.

- الأجهزة الطبية

- تعتبر سبائك النيتينول ضرورية للغرسات والأدوات والأقواس بسبب دقتها وتوافقها الحيوي.

- التطبيقات البحرية

- تتمتع سبائك النيكل بمقاومة التآكل، مما يضمن المتانة في هياكل السفن والمنصات وأنظمة تحلية المياه.

- قطاع السيارات

- تعمل سبائك النيكل على تقوية خزانات الوقود والعوادم وأنظمة التعليق، مما يعزز الأداء في ظروف الضغط العالي.

- قطاع الطاقة

- تتمتع سبائك النيكل بقدرة عالية على مقاومة الحرارة والتآكل في محطات الطاقة والمفاعلات وأنظمة الطاقة المتجددة.

سبائك النيكل مقابل الفولاذ المقاوم للصدأ: أيهما أفضل؟

عند الاختيار بين سبائك النيكل والفولاذ المقاوم للصدأ، من الضروري مراعاة خصائصهما واستخداماتهما الفريدة. تتميز كلتا المادتين بالتفوق في تطبيقات محددة، ولكن الاختلافات بينهما في القوة ومقاومة التآكل والقدرات الحرارية تحدد مدى ملاءمتهما.

ميزة | سبائك النيكل | الفولاذ المقاوم للصدأ |

مقاومة التآكل | استثنائي في البيئات القاسية والمواد الكيميائية | جيد، خاصة في الأجواء المعتدلة والرطبة |

قوة | قوة شد وقوة خضوع أعلى | قوة معتدلة ولكنها متينة للغاية |

مقاومة الحرارة | يعمل بشكل جيد في درجات الحرارة القصوى | فعّالة في مستويات الحرارة المعتدلة |

يكلف | أغلى ثمناً بسبب تركيب المادة | عموما أكثر بأسعار معقولة |

التطبيقات | الصناعات الفضائية والبحرية والكيميائية | البناء والأدوات الطبية وأواني الطبخ |

كما ترى، فإن سبائك النيكل مثالية للبيئات الصعبة التي تتطلب القوة ومقاومة التآكل. من ناحية أخرى، يوازن الفولاذ المقاوم للصدأ بين القدرة على تحمل التكاليف والتنوع، مما يجعله شائعًا للتطبيقات اليومية.

اقرأ المزيد: ألوان الألومنيوم المؤكسد

هل سبائك النيكل تصدأ؟

تتمتع سبائك النيكل بمقاومة عالية للصدأ بسبب قدرتها الطبيعية على تحمل الأكسدة والتآكل. وعلى عكس المواد مثل الفولاذ العادي، الذي يتكون عليه الصدأ عند تعرضه للرطوبة والأكسجين، تحافظ سبائك النيكل على سلامتها البنيوية حتى في البيئات القاسية.

ومع ذلك، في حين أن سبائك النيكل لا تصدأ بالمعنى التقليدي، فإنها يمكن أن تتآكل في ظل ظروف قاسية معينة، مثل التعرض لبيئات شديدة الحموضة أو غنية بالكلوريد.

ملحوظة: الصدأ والتآكل هما حالتان مختلفتان. فمجرد تعرض مادة ما للتآكل لا يعني أنها معرضة أيضًا للصدأ. عليك التأكد من معرفة الفرق بين الاثنين.

الصدأ مقابل التآكل

الصدأ والتآكل هي عمليات مرتبطة ولكنها تختلف في النطاق والمواد المتأثرة.

يشير الصدأ على وجه التحديد إلى أكسدة الحديد أو الفولاذ عند تعرضه للرطوبة والأكسجين، مما يؤدي إلى تكوين أكسيد الحديد البني المحمر. يحدث هذا فقط مع المعادن التي تحتوي على الحديد وهو واضح للغاية، وغالبًا ما يؤدي إلى ضعف البنية بمرور الوقت.

من ناحية أخرى، يعتبر التآكل مصطلحًا أوسع نطاقًا يصف التدهور التدريجي لأي مادة - معدن أو خرسانة أو بوليمر - بسبب عوامل كيميائية أو بيئية. يمكن أن تشمل هذه العملية الأكسدة، ولكن أيضًا تفاعلات أخرى مثل تلك التي تسببها الأحماض أو الأملاح.

هل سبائك النيكل آمنة للطعام؟

بشكل عام، نعم، يمكنك حفظ وتخزين الطعام في سبائك النيكل، مما يجعله آمنًا للطعام. في الواقع، يعتبره الكثيرون مكونًا أساسيًا في سلسلة توريد الطعام لأنه لا يغير تكوين وبنية الطعام.

ال معهد النيكل تعتبر سبائك النيكل آمنة للأغذية لأنها لا تلوث أو تغير لون الطعام، كما أنها مقاومة للتآكل والتلف ومقاومة للحرارة.

اقرأ المزيد: ما هو الصب بالقالب: العملية والتطبيقات والمواد

لماذا نستخدم HDC لسبائك النيكل؟

منذ أكثر من عقد من الزمان، نعمل في HDC في مجال توفير مكونات ومواد عالية الجودة. ويمتد هذا من أبسط صناعات السيارات والنقل إلى صناعة الطيران والطب والتصنيع وغير ذلك الكثير!

تعد سبائك النيكل جزءًا من منتجاتنا الأكثر طلبًا، لكن أعمالنا لا تتوقف عند هذا الحد. فنحن نعتبر أيضًا من الشركات المصنعة الرائعة لـ المواد البلاستيكية, سبائك النحاس, منتجات الفولاذ المقاوم للصدأو الكثير غيرها!

نحن مسلحون بخبراء يمتدون من بناء المواد وتوفيرها إلى الهيكلة الإبداعية. تواصل معنا اليوم وسوف نكون أكثر من سعداء لإرسال عرض أسعار مجاني إليك!

اكتشف المزيد مع منشورات مدونتنا.

المشاركات الاخيرة

اكتشف المزيد عن منتجاتنا.

المنتجات ذات الصلة

اقتباس فوري!