The process of heat treatment changes how a metal acts. It improves traits like hardness, strength, and flexibility to help the parts last longer and be more efficient. This process proves to be very useful in various industries, such as automotive, aerospace, and toolmaking.

What Is Heat Treatment?

Heat treatment is a method of changing a metal’s internal structure through precise heating and cooling cycles. This either makes the metal stronger or softer and easier to shape.

The main aim of heat treatment is to improve the metal’s hardness and strength. Not only that, but it also improves its ductility and resistance to rust. This process has been used for many years. Early blacksmiths used heating and cooling processes to forge tools and swords. Today, factories use high-tech equipment for the same process.

How Heat Treatment Works: The Basic Process

This process follows three main steps, and each must be followed correctly for the best outcome:

- Heating: Here, the metal you’re working with is heated to a certain temperature. The temperature used depends on the metal.

- Holding: This is when the workpiece is kept at the set temperature for a while, allowing it to spread evenly throughout the part.

- تبريد: The metal is then cooled in a controlled way, which affects the internal structure.

The cooling speed also affects how hard the metal turns out. If it is done rapidly, the part becomes very hard, while if it’s done slowly, it makes the metal soft. The heating environment, whether it’s air, vacuum, salt bath, or gas, all serve different purposes.

Salt baths ensure the metal parts are heated evenly, while a vacuum space helps prevent unwanted reactions.

Types of Heat Treatment Processes

التلدين

This process is used to soften metals, making them more ductile and easier to work with. It also removes stress from the shaping or cutting processes. It is commonly used for making sheet metal and tools.

التطبيع

This is a process that’s usually used on forged or cast steel. It gives the metal a uniform grain structure, improving its toughness and making the metal more stable.

التصلب

Hardening is used to improve the surface hardness of the metal. The part is heated up and cooled down quickly, forming a hard structure inside it called martensite. This structure is usually brittle, so the process is followed by tempering.

التلطيف

Here, the brittleness of the workpiece is reduced, and the toughness is also improved. The part is reheated to a lower temperature and held for a while to balance its strength and flexibility.

إخماد

Here, the metal is cooled very quickly. Different mediums can be used to cool at different speeds, such as water, air, or oil.

تصلب العلبة (Carburizing, Nitriding)

This process hardens only the surface of the workpiece, but the inside remains soft. Carburizing adds carbon to the surface of the metal, while Nitriding uses nitrogen gas to form a hard surface. Both methods improve the part’s resistance to rust.

Heat Treatment of Different Metals

فُولاَذ

This is the most commonly used metal when it comes to heat treatment. The carbon content in it can be adjusted to change how hard or tough it becomes. Different heating and cooling methods can be used to change its structure.

سبائك الألومنيوم

When applying heat treatment to aluminum, the process can be quite tricky. Since it melts at a lower temperature than steel, the heat needs to be controlled carefully. Aluminum is mostly hardened through precipitation hardening, which improves its strength.

Copper, Titanium, and Other Alloys

Other metals and alloys can also be heat-treated. Copper is usually softened through annealing, while some other copper alloys can be hardened. When heat treating titanium alloys, it needs to be done with care because they react with oxygen when hot.

Benefits of Heat Treatment

موارد: AZom-How Does Heat Treatment Change the Properties of Steel?

There are many advantages you get when heat treating metals, such as:

- The process improves the mechanical properties of metals, making them last much longer under stress.

- It also makes it easier to work with metals by making them softer through processes such as annealing. Hard metals also hold edges for a longer period.

- Heat-treated parts have better resistance to wear and corrosion, which is important for tools exposed to acidic environments.

- The process also enhances the dimensional stability of parts, which relieves internal stress and prevents the part from warping over time.

Heat Treatment Equipment and Technology

Most factories use special equipment and tools to control the heat treatment processes.

Furnaces

There are different kinds of furnaces used in the heat treatment process. Batch furnaces are used to treat one load at a time, and it is best used for small parts. Continuous furnaces keep the moving parts through a long heating tunnel and are best used for high-volume work.

على الجانب الآخر، vacuum furnaces keep the air out to prevent rust or any surface damage. They are mostly used for clean, high-precision work.

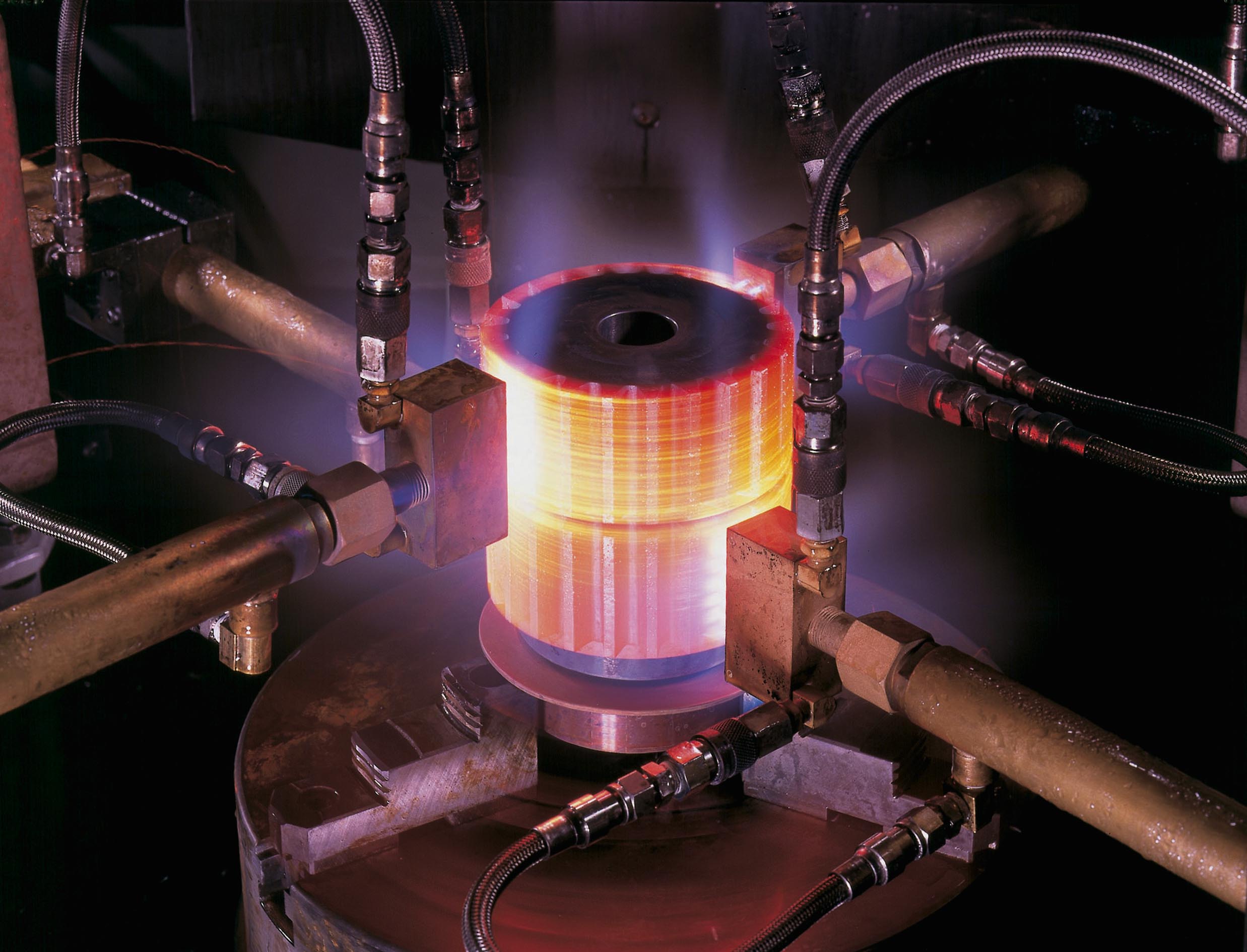

Induction & Laser Hardening

Induction hardening uses magnetic fields to heat the surface of the workpiece quickly. It works very well when making shafts or gear teeth. Laser hardening, however, does the same, but with a very hot and precise beam to heat a small spot.

Control Systems

These control systems are used to monitor the temperature and time closely. They help to ensure the metal gets the correct treatment needed for the work.

Common Applications of Heat Treatment

Automotives

A lot of heat-treated parts are used in the automotive industry for their strength. Some of these parts are:

- التروس

- أعمدة الكرنك

- Axles

These parts needed to be heat-treated because they usually carry heavy loads. If the process is not done, the parts would wear out quickly.

الفضاء الجوي

Parts used in aircraft usually experience a lot of heat and pressure. Heat treatment is used to make parts, like:

- Blades

- Landing gear

- Aircraft frames

Tooling

Heat treatment is also important when making various kinds of work tools. These include:

- Drill bits

- Dies

- Molds

These parts need to maintain hardness without being brittle. You can achieve this process through controlled heating and cooling methods.

السلع الاستهلاكية

Most of the items we use daily also need proper strength and shape control. Heat treatment is used for items such as:

- Knives

- Springs

- براغي

Choosing the Right Heat Treatment Process

Choosing the right process for your job depends on different factors.

Type of Material and Properties

The type of metal you’re working with tells you the options you have. The contents of alloys can affect the temperature and cooling rates. High-carbon steel handles the hardening process well, but you need to be more cautious when working with aluminum.

It’s also necessary to take note of the properties you want, whether it’s strength or wear resistance.

Professional Consultation

If you’re not sure about what to do, it’s best to ask a professional for help. They best understand how metals work and will save you from making mistakes and wasting money.

خاتمة

Every part you build depends on the strength of the metal. Heat treatment helps you meet the strength, hardness, or flexibility needs of your project. If you’re looking to get started today, our team is here to help you.

اكتشف المزيد مع منشورات مدونتنا.

المشاركات الاخيرة

اكتشف المزيد عن منتجاتنا.

المنتجات الحديثة

اقتباس فوري!