Fabricante de piezas de maquinaria agrícola forjadas personalizadas y OEM

Gracias a sus capacidades de forjado y acabado CNC de precisión, HDC ofrece componentes forjados para reemplazos OEM o para construir nuevas máquinas agrícolas bajo su marca.

Componentes de enganche y remolque forjados

Estos componentes son esenciales para la conexión de seguridad y el remolque. HDC los forjó con material de alta resistencia, diseñados para aplicaciones de servicio pesado.

Horquilla forjada

Una horquilla en un sistema de remolque a menudo necesita soportar fuerzas de impacto lateral, por lo que HDC utiliza principalmente forjado en matriz cerrada para mejorar la tenacidad, lo que reduce significativamente el riesgo de agrietamiento por fatiga.

Ojo de barra de tiro

Utilizado como interfaz de conexión entre tractores e implementos, los factores clave son la estabilidad dimensional y la redondez del orificio. Forjamos la forma y luego la acabamos con CNC para garantizar un ajuste preciso con el pasador.

Gancho de remolque

Los ganchos de remolque se centran en la geometría y el grosor del diseño. Podemos modificar la pieza basándonos en muestras de camiones o maquinaria agrícola originales, ajustando la curvatura de las orejas y el ángulo de apertura para facilitar la instalación y un uso más suave.

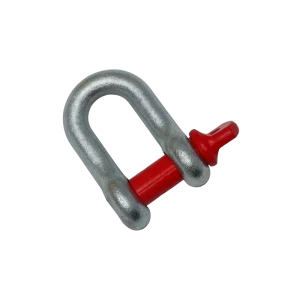

Grilletes

Los grilletes se utilizan a menudo en situaciones que requieren un montaje y desmontaje frecuentes. HDC los forja en acero aleado o acero al carbono para lograr mayores cargas de rotura y ofrece diferentes tratamientos superficiales según el entorno operativo.

Piezas forjadas para arados y labranza

HDC forja componentes de arado y labranza de alta resistencia diseñados para soportar condiciones de suelo difíciles.

Arado de cincel

La barredora está diseñada para cortar el suelo eficientemente. Debe soportar la abrasión constante del suelo y el posible impacto con rocas. Mediante el forjado, HDC la fabrica con alta resistencia y un espesor constante del filo de la cuchilla.

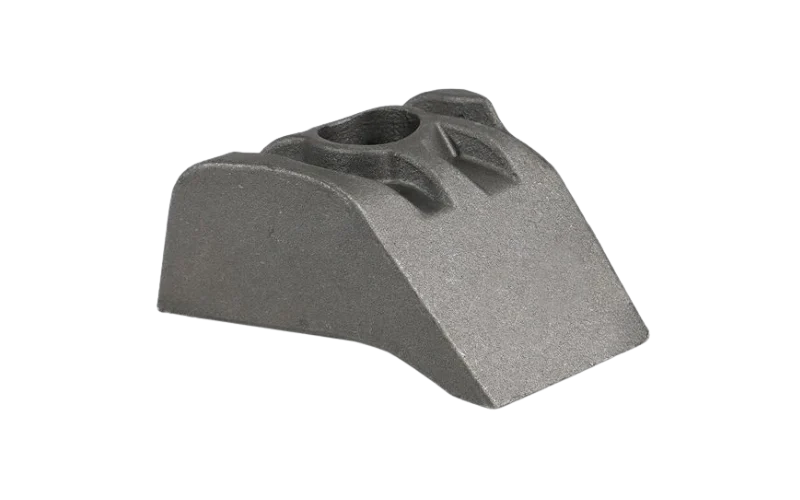

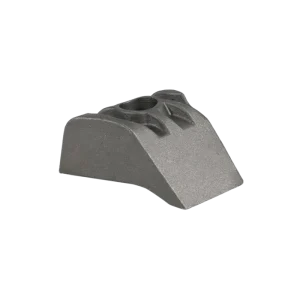

Punta de arado de cincel

La punta del arado es el componente clave del subsolador. Debe ser lo suficientemente resistente como para penetrar en terrenos duros y penetrar profundamente bajo la enorme fuerza de arrastre. HDC lo consigue forjándolo con aleaciones de alta resistencia.

Vástago de arado de cincel

El vástago del arado es un puente que conecta el armazón con la punta o barredora. Esto significa que debe ser resistente y tenaz para evitar la flexión y la fractura bajo tensión e impacto. Al forjarlo con materiales de alta calidad, podemos cumplir fácilmente con los requisitos.

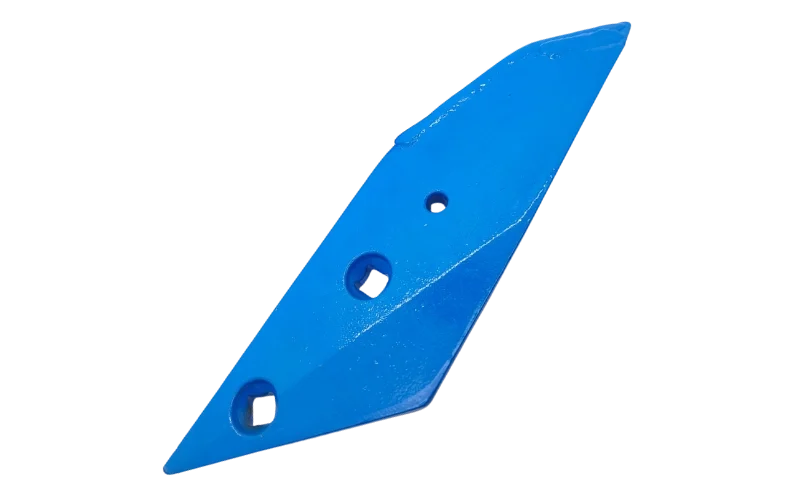

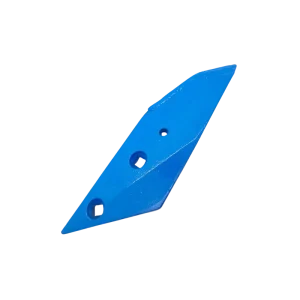

Reja del arado

La reja de arado es una placa de cuchilla con superficie curva que se utiliza para cortar la tierra, cortar residuos de cultivos y raíces, a la vez que la voltea lateralmente. HDC la fabrica con acero resistente al desgaste para evitar el desgaste, el astillado y las fracturas.

Componentes de corte para cosechadoras forjados

Estas piezas hacen el trabajo real de corte y trilla, por lo que HDC las forja para que sean resistentes y las trata para que sean resistentes al desgaste.

Protector de cuchillas para cosechadora

El protector de cuchilla es una protección triangular o de dedo que protege la cuchilla alternativa, ordenando los tallos y evitando que se enreden. HDC puede personalizarlo con cualquier tipo de cuchilla que desee, utilizando acero de alta resistencia.

Barra/dientes de raspador

La barra y el diente de la desgranadora son componentes clave del sistema de trilla de una cosechadora, utilizados para separar el grano de los tallos mediante golpes y frotamiento. En este proceso, deben soportar vibraciones e impactos de alta frecuencia. Por ello, suelen fabricarse mediante forja.

Cabezal de cuchilla cosechadora

El cabezal de corte cuenta con orificios uniformemente espaciados para fijar la cuchilla y una varilla de conexión en un extremo para conectarlo al sistema de accionamiento de la cuchilla, que funciona como pieza de conexión. HDC puede personalizarlo según su diseño para adaptarse a cualquier modelo de cosechadora.

Sección de hoz de la cosechadora

La sección de la hoz suele ser una cuchilla de doble filo atornillada a la barra de corte. Durante la cosecha, realiza un movimiento alternativo, creando una acción de corte similar a la de una tijera con la protección. Para mantener el filo, HDC suele forjarla con acero para herramientas.

Componentes de transmisión y motor forjados

Estas piezas permiten que la potencia fluya del motor a las ruedas o implementos. HDC las forja para soportar cargas pesadas y evitar fallas que podrían interrumpir su operación.

Junta universal del tractor

Las juntas universales permiten que los ejes de transmisión se conecten en ángulo al girar. La pieza transversal recibe impactos desde múltiples direcciones al girar. Las forjamos para que el metal se adapte a la forma, lo que ayuda a prevenir grietas en la unión de las tapas de los cojinetes.

Yugo de brida

La horquilla de brida se atornilla a la caja de cambios y se conecta al eje de transmisión. Todos esos orificios para tornillos y la forma de la horquilla crean puntos débiles si no se tiene cuidado. Forjarla como una sola pieza sólida significa que ninguna junta puede fallar.

Yugo de la toma de fuerza

Las horquillas de la TDF conectan la potencia de su tractor al implemento que esté utilizando. Resisten mucho cuando el equipo se activa, especialmente en el extremo estriado. Las forjamos para que soporten mejor las cargas de impacto y resistan el giro constante.

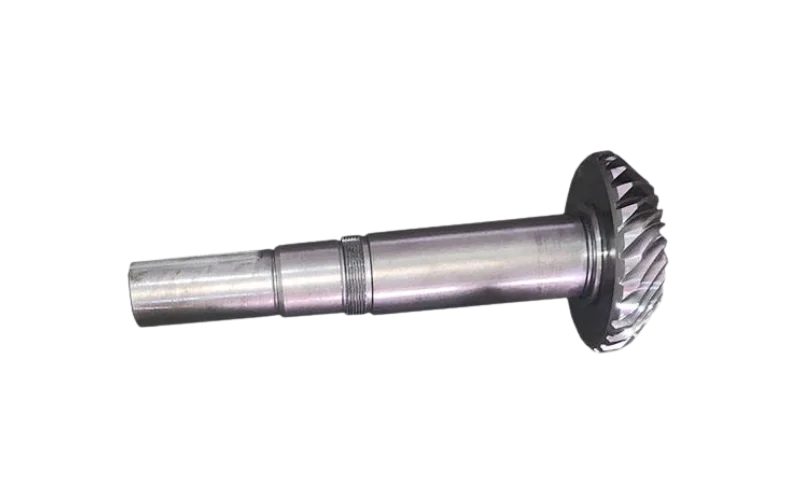

Engranaje de tractor

Los engranajes de transmisión engranan miles de veces durante su funcionamiento. La parte inferior de cada diente absorbe la mayor parte de la fuerza de flexión. El forjado moldea la estructura interna para un mejor soporte de los dientes, y posteriormente endurecemos la superficie para resistir el desgaste.

¿Por qué elegir HDC?

Por qué HDC es su socio ideal para piezas personalizadas de maquinaria agrícola. Aquí tiene la respuesta.

Forjado personalizado según sus especificaciones

Trabajamos a partir de sus muestras y planos. Nuestro equipo de ingeniería puede aplicar ingeniería inversa a piezas OEM o modificar diseños para mejorar el rendimiento.

Control total del proceso

Nos encargamos de todo internamente: forja, tratamiento térmico y mecanizado CNC. Esto se traduce en menos traspasos y mayor consistencia.

Conocemos los equipos agrícolas

HDC lleva años fabricando piezas para tractores, arados y cosechadoras. Entendemos cómo fallan estos componentes y qué necesitan para funcionar correctamente en el campo.

Precio competitivo

Compra directamente de fábrica. Reducimos los costos al realizar todo internamente y usar forja para minimizar el desperdicio de material.

Cómo fabricar piezas de maquinaria agrícola personalizadas de HDC

Desde la forja hasta el producto final, HDC fabrica las mejores piezas de maquinaria que necesita.

Forjar

Comenzamos forjando la pieza hasta alcanzar su forma final. Este proceso adapta la estructura interna del metal a las tensiones a las que se someterá la pieza durante su uso. Para piezas agrícolas que soportan impactos y cargas pesadas, los componentes forjados ofrecen una resistencia mucho mayor que las alternativas fundidas o mecanizadas a partir de barras.

Tratamiento térmico

El tratamiento térmico es donde ajustamos el rendimiento de la pieza. Dependiendo de la función del componente (cortar tierra, absorber impactos o resistir el desgaste), ajustamos el proceso de calentamiento y enfriamiento para lograr el equilibrio perfecto entre dureza y tenacidad para esa aplicación específica.

Acabado CNC

Tras el forjado y el tratamiento térmico, mecanizamos las características críticas con tolerancias estrictas. Los orificios de montaje, las superficies de contacto y cualquier dimensión que afecte al ajuste se procesan mediante CNC. Esto garantiza que sus piezas se atornillen correctamente y funcionen a la perfección con el resto de su equipo.

Echa un vistazo a nuestro control de calidad Métodos para forjar piezas.

Materiales disponibles

Comience con el material de alta calidad que proporciona HDC y obtendrá las mejores piezas como resultado.

El acero al carbono es una opción rentable para piezas agrícolas, ya que se puede moldear fácilmente mediante forja y su precio es menor. Las piezas fabricadas con este material son ideales para aplicaciones generales como vástagos, soportes y componentes estructurales que no requieren resistencia a la corrosión.

HDC ofrece grados de acero al carbono que incluyen Q355B, Q235, 20#, y 45# Para forjar piezas agrícolas.

El acero aleado contiene elementos añadidos como cromo y molibdeno para mejorar su resistencia y tenacidad. Las piezas de acero aleado duran más tiempo bajo fuertes impactos y desgaste. Lo utilizamos para componentes sometidos a un uso intensivo, como puntas de arado, barras de trilla y piezas de transmisión.

Los grados comunes de acero de aleación que forjamos incluyen 20Cr, 20CrMo, 40Cr y 42CrMo.

El acero inoxidable se utiliza para piezas expuestas a la humedad, fertilizantes o productos químicos, ya que resiste la corrosión. Los componentes de corte, como las protecciones de cuchillas y las secciones de hoz, fabricados con este material no se oxidan. Su coste es mayor que el del acero al carbono, pero evita tener que reemplazar piezas corroídas con frecuencia.

HDC forja piezas agrícolas de acero inoxidable a partir de 304, 316L, 1.4301, 1.4462 y 1.4571.

Acabados disponibles

Al ofrecer acabados de superficie integrales, HDC puede satisfacer todas sus necesidades de personalización.

El recubrimiento en polvo es un acabado duradero que se aplica comúnmente a piezas metálicas utilizadas en la agricultura. Ofrece mayor resistencia a la corrosión que la pintura y proporciona una apariencia lisa y uniforme. Con diferentes polvos, se pueden obtener piezas con diferentes colores y propiedades de resistencia a la corrosión.

Este acabado se utiliza a menudo para componentes y piezas que están expuestas a fertilizantes, productos químicos o a la intemperie constante.

El zincado se aplica comúnmente a piezas agrícolas para lograr un equilibrio entre la anticorrosión y el costo. Las piezas galvanizadas resisten mejor la oxidación al exponerse a la lluvia, la humedad y las condiciones del campo.

HDC ofrece diferentes opciones de galvanizado, incluido zinc transparente, zinc amarillo y zinc negro, según sus requisitos de resistencia a la corrosión.

El óxido negro es un tratamiento superficial universal para piezas de maquinaria agrícola. Proporciona una ligera protección contra la corrosión y reduce el deslumbramiento. Las piezas tratadas con este tratamiento se utilizan principalmente en entornos secos o en condiciones de almacenamiento en interiores.

Este acabado es rentable y se aplica comúnmente a piezas como vástagos, soportes y componentes que no están expuestos a la humedad constante.

Especificaciones técnicas

Obtenga una comprensión completa de nuestras capacidades de fabricación antes de solicitar una cotización.

| Peso máximo de una sola pieza | 0,01 kg – 30 kg |

| Capacidad de la prensa de forja | 160T – 4000T |

| Dimensiones máximas | Longitud: hasta 500 mm Ancho: hasta 500 mm Espesor: 5 mm – 200 mm |

| Tolerancia de mecanizado | ±0,05 mm – ±0,2 mm (según características) |

| Rugosidad de la superficie | Ra 1,6 – 6,3 μm (después del mecanizado) |

| Rango de diámetro del orificio | Ø6 mm – Ø200 mm |

| Especificaciones de rosca | M6 – M64 (métrico), roscas personalizadas disponibles |

| Tratamiento térmico | Temple, revenido, normalizado y carburado |

| Rango de dureza | HRC 25 – 60 (dependiendo del material y la aplicación) |

| Volumen de producción | Desde 10 piezas hasta más de 50.000 piezas |

¿Estás listo para comenzar tu pedido personalizado?

Desde la muestra hasta la producción, HDC entrega los componentes agrícolas forjados que necesita.

Preguntas más frecuentes

¿Qué son las piezas agrícolas forjadas?

Las piezas forjadas se fabrican mediante procesos de forja como la forja en matriz cerrada y la forja por estampación. Esto proporciona una estructura interna más resistente que la fundición o el mecanizado a partir de barras. La mayoría de los componentes agrícolas de alta resistencia, como puntas de arado, vástagos y horquillas de toma de fuerza, se forjan porque deben resistir impactos y tensiones sin agrietarse.

¿Puedes forjar piezas agrícolas personalizadas a partir de mi muestra?

Sí. Simplemente envíenos su muestra o dibujo y determinaremos el material y el proceso necesarios para fabricar una réplica perfecta.

¿Cuál es la cantidad mínima de pedido para piezas forjadas personalizadas?

Depende de si necesitamos nuevas herramientas. Las piezas sencillas con matrices existentes pueden empezar con 10-50 piezas. Las herramientas personalizadas suelen requerir entre 100 y 500 piezas para que sean viables. Podemos hablar sobre opciones de prototipos si necesita muestras previamente.

¿Qué material es mejor para las puntas de arado de cincel?

El acero con contenido medio a alto de carbono, como el 45#, es ideal para la mayoría de las aplicaciones. Si golpea rocas con frecuencia, el acero de aleación, como el 40Cr o el 42CrMo, dura más. La punta se endurece a aproximadamente HRC 48-52, mientras que la zona de conexión se mantiene más blanda para mayor resistencia.

¿Cómo elegir entre rejas de arado forjadas y fundidas?

Las rejas de arado forjadas son más resistentes y mantienen el filo por más tiempo. Las de fundición son más económicas, pero se desgastan más rápido y se agrietan con mayor facilidad, especialmente en suelos rocosos. Si realiza trabajos pesados o desea piezas que duren varias temporadas, opte por las forjadas.

¿Qué provoca que los protectores de cuchillas de la cosechadora se desgasten rápidamente?

La hoja se desliza constantemente sobre la guarda, desgastando la superficie de la guía. Si a esto le sumamos la suciedad, las fibras de los cultivos y, ocasionalmente, las piedras, se desgastan rápidamente. Un acero de mejor calidad y un endurecimiento adecuado prolongan su vida útil.

¿Se pueden forjar yugos de toma de fuerza para diferentes modelos de tractores?

Sí, pero necesitamos que el tamaño de las estrías y el número de dientes coincidan con los de su tractor. Envíenos una muestra del yugo o las especificaciones (como 1-3/8″ con 6 estrías) y podemos forjarlo. Las estrías personalizadas suelen requerir herramientas nuevas.

¿Qué tratamiento térmico es mejor para las piezas agrícolas?

Depende de la pieza. Los filos deben ser duros (HRC 48-55). Las piezas flexibles, como los vástagos, deben ser resistentes pero no quebradizas (HRC 35-42). Las piezas de impacto deben ser resistentes a los impactos. Recomendamos un tratamiento según el uso que se le dé a la pieza.