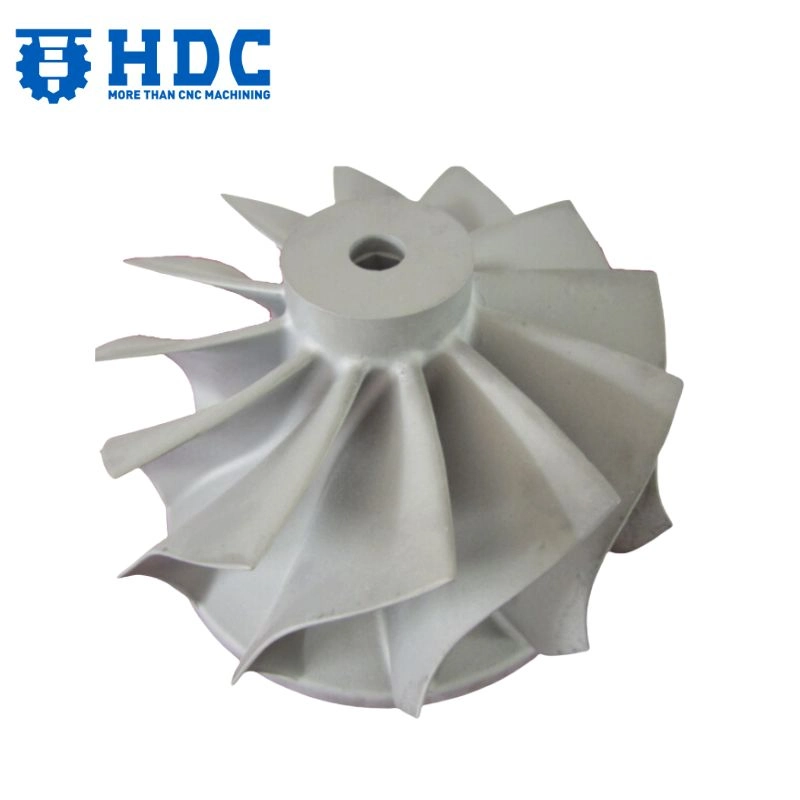

Impulsor de ventilador de acero/aluminio/superaleación/latón personalizado, fundición a la cera perdida, impulsor de bomba abierta

Detalles del producto personalizado

| N º de Modelo. | HDCIFI002 |

| Estilo | Impulsor de ventilador de fundición de inversión |

| Material | Aluminio, aleación de aluminio, acero, aleación de acero, acero inoxidable, superaleación, latón |

| Tipo de acabado | Sin acabado, pulido, anodizado, recubierto electroforéticamente, recubierto con pintura en polvo, galvanizado, cromado, oxidado negro |

| Talla disponible | / |

| Cantidad mínima de pedido | 100 piezas |

| Logotipo personalizado | Disponible |

| Origen | Porcelana |

| Empaquetado y entrega | |

| Opción de envío | Mensajería, aire, mar, ferrocarril expreso, EXW, FOB, CIF, DDU, DDP |

| Fecha de entrega | 25-30 días |

| Paquete de transporte | Personalizado, Cartón, Palet |

Conquer the toughest fluid-handling challenges with this custom lost wax cast fan and open pump impeller. Precision-engineered for applications involving solids-laden media, fibrous entanglements, or high-velocity airstreams, this component delivers optimized aerodynamic and hydrodynamic performance through integrally cast blade architecture—delivered with the clog-resistant efficiency and material flexibility only investment casting can provide.

Selección de materiales multialeación: Available in high-strength steel, lightweight aluminum, advanced superalloy, or corrosion-resistant brass—each precision-selected to match specific operating speeds, media temperatures, abrasion potential, and environmental exposure requirements.

Lost Wax Cast Complex Blade Geometry: Precision investment casting enables the formation of intricately contoured vanes, variable pitch angles, and blended leading-edge profiles in a single, monolithic structure—unattainable through conventional machining or multi-piece fabrication while preserving aerodynamic/hydraulic design intent.

Open-Design Anti-Clogging Efficiency: Strategically configured vane spacing and swept-back blade architecture efficiently process fluids containing suspended solids, fibrous materials, or entrained gases—maintaining consistent output while resisting ragging, binding, and flow degradation.

Integridad estructural monobloque: Single-piece, integrally cast construction eliminates welded joints, mechanical fasteners, and stress-prone assembly interfaces—ensuring dimensional stability and balance retention under continuous high-speed operation.

Optimized Aerodynamic/Hydrodynamic Performance: Precision-cast surface finishes and mathematically modeled inter-vane channel geometry minimize turbulence, reduce parasitic losses, and maintain efficient energy transfer across the specified duty curve.

Fully Customizable Operating Parameters: Manufactured to customer-specific vane counts, exit diameters, hub configurations, and speed/torque requirements—accommodating everything from high-flow/low-head wastewater mixing to high-static-pressure industrial ventilation.

Ingeniería de superficies adaptada a la aplicación: Available with optional hard coatings, erosion-resistant claddings, or chemical barrier treatments—providing lasting protection against abrasive slurries, cavitation damage, and corrosive fluid media.

Aplicaciones:

Wastewater & Effluent Handling: Ideal for lift stations, treatment plant recirculation, and industrial effluent transfer requiring reliable solids handling with minimized maintenance intervention.

Industrial Ventilation & Air Movement: Essential for fume extraction, process cooling, and material conveyance systems demanding efficient airfoil performance with verified flow and pressure characteristics.

Agricultural & Irrigation Pumping: Suitable for flood irrigation, slurry transfer, and livestock waste handling where fibrous materials and suspended solids are present.

Marine & Offshore Bilge Systems: Engineered for deck washdown, engine room bilge pumping, and ballast transfer requiring clog-resistant operation in debris-laden seawater.

Procesamiento de alimentos y bebidas: Ideal for whole product transfer, vegetable fluming, and effluent streams containing organic solids without shearing or degradation.

More than a rotating vane assembly, this investment-cast open impeller is the fluid-dynamic solution to impossible media—maintaining flow when solids obstruct, preserving efficiency when fibers entangle, and delivering reliable performance when conventional impellers fail. Whether you’re engineering municipal wastewater infrastructure or industrial process ventilation, it’s the component that proves pumping confidence begins with precision-cast, clog-resistant continuity.