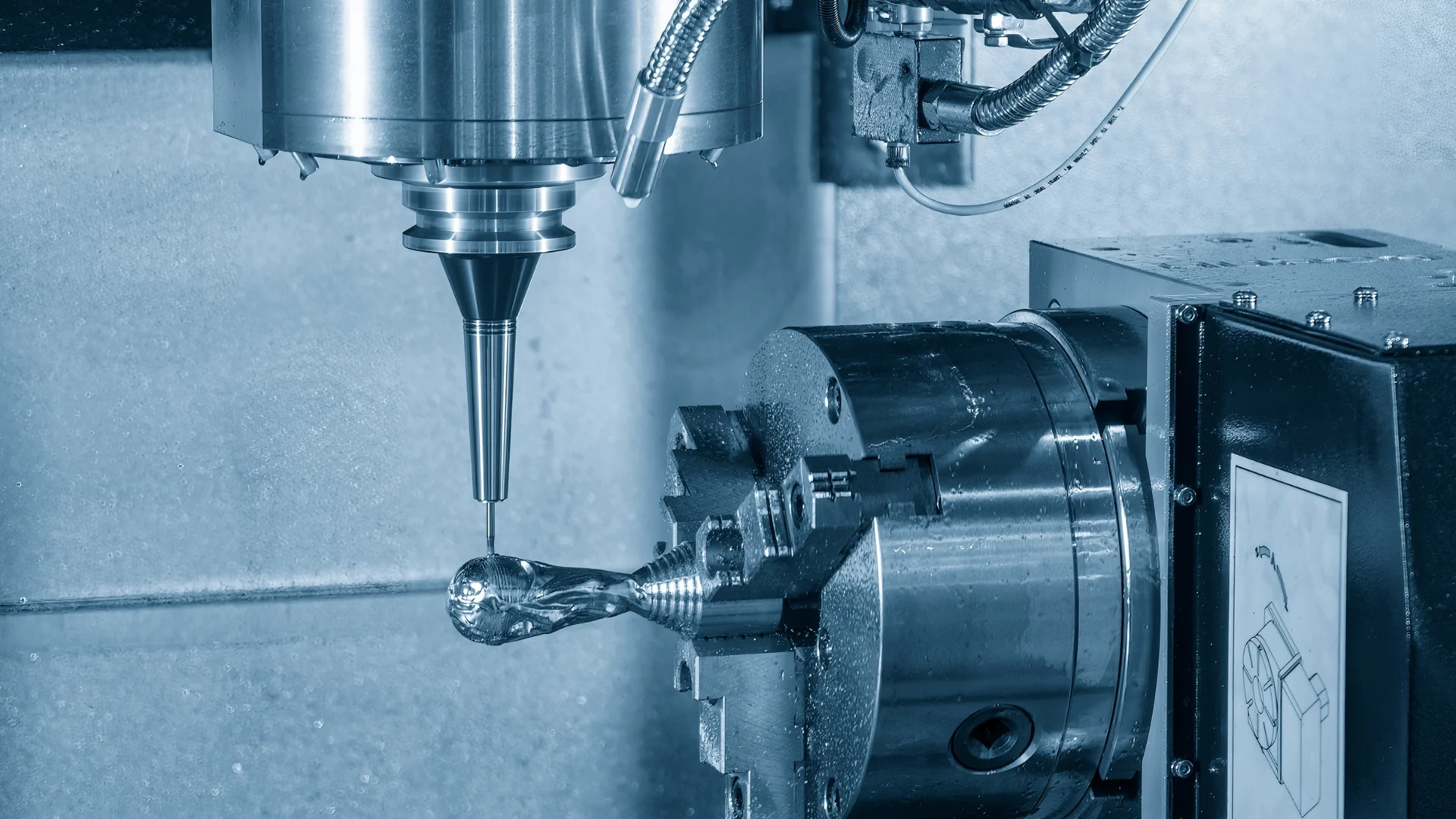

Inicio Dominar el mecanizado con tecnología CNC avanzada Servicio de fresado CNC...

Premium Aluminum CNC Machining Service

Professional aluminum CNC machining service with over decades of expertise brings high quality aluminum parts for global industries.

• Solución personalizada

• Calidad certificada ISO

• Global Service

Aluminum Alloys & Surface Finishes

HDC offers a wide range of aluminum alloys and surface finishes to satisfy different project requirements

Aluminum Alloy 2024 (AlCu4Mg1)

2024 is a high-strength alloy with the advantage of having high fatigue strength.

Its main alloying elements are copper and a small amount of magnesium. The processing performance is acceptable, but not as good as 6061. The disadvantage of 2024 is that the corrosion resistance is very poor, so the coating protection is usually required. T3 and T4 are common tempers for 2024.

2024 is primarily used in aircraft structural parts, rivets, truck wheels, and other applications that require high strength and good fatigue properties. CNC machining is commonly used to manufacture prototypes, low-volume parts, or repair parts.

Aluminum 2024 Properties

| Densidad (g/cm³) | Hardness (HB) | Resistencia a la fluencia (MPa) |

|---|---|---|

| 2.78 | 120 | 345 |

Aluminum Alloy 5052 (AlMg2.5)

The main alloying element of 5052 is magnesium, which has medium strength but excellent corrosion resistance, good formability (bending, stamping) and weldability. H32 is its usual state.

It is mainly used for parts that require excellent corrosion resistance, such as ship parts. When strength and hardness are not primary considerations, and corrosion resistance is key, 5052 is an excellent choice.

Aluminum 5052 Properties

| Densidad (g/cm³) | Hardness (HB) | Resistencia a la fluencia (MPa) |

|---|---|---|

| 2.68 | 60 | 193 |

Aluminum Alloy 6061 (AlMg1SiCu)

6061 is the most used aluminum alloy, mainly composed of magnesium and silicon. It has good strength, weldability, and corrosion resistance, excellent processing performance.

Typically, the T6 state (solution heat treatment + artificial aging) is used to obtain the best overall performance.

It is widely used in various structural parts, brackets, shells, auto parts, bicycle parts, consumer electronics parts, etc. Ideal for applications that require good overall performance and processability.

Propiedades del aluminio 6061

| Densidad (g/cm³) | Hardness (HB) | Resistencia a la fluencia (MPa) |

|---|---|---|

| 2.7 | 95 | 276 |

Aluminum Alloy 6063 (AlMg0.7Si)

6063 is part of the same 6000 series as 6061, but slightly less powerful than 6061. Its main alloying elements are the same as 6061, but the content is lower than that. T5 and T6 are its commonly used states.

6063 has excellent extrusion properties and is mainly used for extrusion profiles (door and window frames, radiators, etc.). CNC machining is often used to perform secondary processing on extruded profiles to manufacture final parts.

Aluminum 6063 Properties

| Densidad (g/cm³) | Hardness (HB) | Resistencia a la fluencia (MPa) |

|---|---|---|

| 2.7 | 73 | 214 |

Aluminum Alloy 6262

6262 is an alloy specially designed to improve cutting performance, on the basis of maintaining good strength and corrosion resistance, elements such as lead and bismuth are added, so that its cutting performance is very good. T6, T651, T9 are its commonly used tempers.

It is especially suitable for parts that require high-volume, high-efficiency, high-quality machining, such as hydraulic valve blocks, connectors, threaded parts, and parts that require complex contours and fine details.

Aluminum 6062 Properties

| Densidad (g/cm³) | Hardness (HB) | Resistencia a la fluencia (MPa) |

|---|---|---|

| 2.7 | 95 | 276 |

Aluminum Alloy 7075 (AlZn5.5MgCu)

7075 is an ultra-high-strength aluminum alloy, the main alloying elements are zinc, magnesium, and copper.

The strength of 7075 is more than 2 times that of 6000 series alloys, close to some steels, with T6 being the most commonly used high-strength temper. It has high hardness and good wear resistance, but the processing performance is not as good as 6061, and the corrosion resistance is poor.

7075 is commonly used in applications where strength is the primary consideration for aerospace structural parts (e.g., aircraft frames) and high-performance bicycle parts (frames, forks).

Propiedades del aluminio 7075

| Densidad (g/cm³) | Hardness (HB) | Resistencia a la fluencia (MPa) |

|---|---|---|

| 2.81 | 150 | 503 |

Anodizado

Color anodizing and hard anodizing are available

Laser Marking

Permanent precision engraving for traceability and branding

galvanoplastia

Nickel/chrome plating enhances wear resistance and aesthetics

Recubrimiento en polvo

Electrostatically applied polymer finish with UV and impact resilience

pasivación

Chemical removal of free ions to prevent oxidation spots

¿Necesita diferentes opciones?

Aluminum alloys and finishes shown above are just part of our options for custom CNC aluminum service. Contact us for more information.

Industria a la que servimos

Las piezas forjadas de acero son las preferidas por la industria global por su rentabilidad y su rendimiento excepcional.

Aeroespacial

- Soportes estructurales para aeronaves

- Engine mounting plates

- UAV (drone) frames

- Partes del tren de aterrizaje

Automotor

- Engine blocks and cylinder heads

- Transmission housings

- Componentes de suspensión

- Wheels and wheel spacers

Electrónica

- Conjuntos de disipadores de calor

- Server chassis

- Semiconductor tooling plates

- 5G antenna housings

Médico

- Componentes de la máquina de resonancia magnética

- Prosthetic joints

- Mangos de instrumentos quirúrgicos

- Dental equipment

Bienes de consumo

- Camera body shells

- Sports equipment frames

- Smartphone structural elements

- High-end audio components

Renewable Energy

- Solar panel mounting frames

- Wind turbine pitch controllers

- Power inverter housings

- Hydroelectric valve bodies

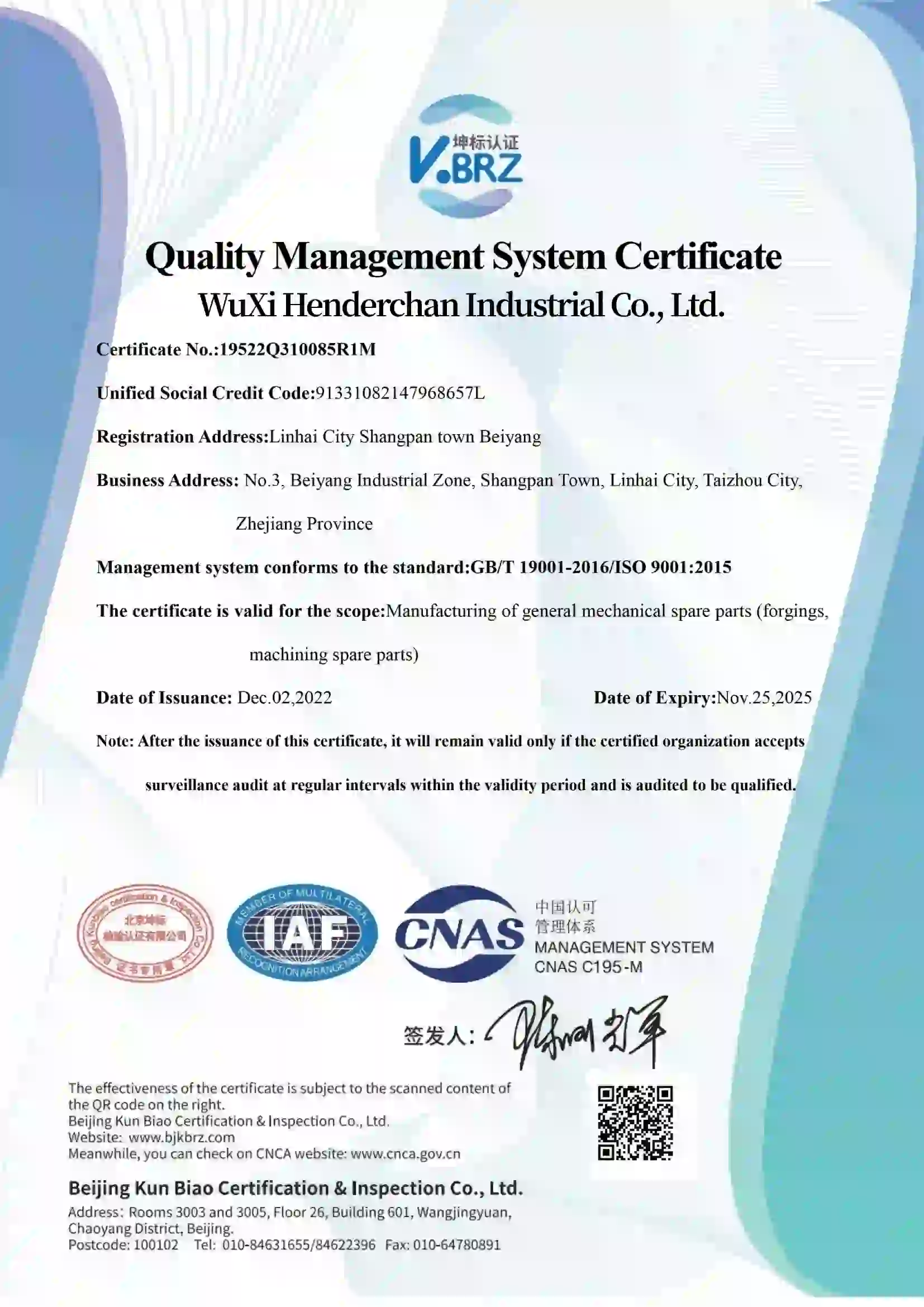

Comprehensive Quality Assurance

HDC is certified by international quality and environmental management standards, including ISO and IATF. We follow the strict quality control protocol to ensure every product we machine meets your expectations.

Material Validation

Inspect material composition and physical properties to ensure quality

En proceso de inspección

Real-time monitoring of machining accuracy and critical dimensions

GD&T Compliance

erify geometric tolerances via CMM scanning and optical measurement

After-Sale Service

Rapid response for quality issues with technical support guarantee

¿Por qué elegir HDC?

6 competitive advantages in precision manufacturing, proven by 50+ advanced machines.

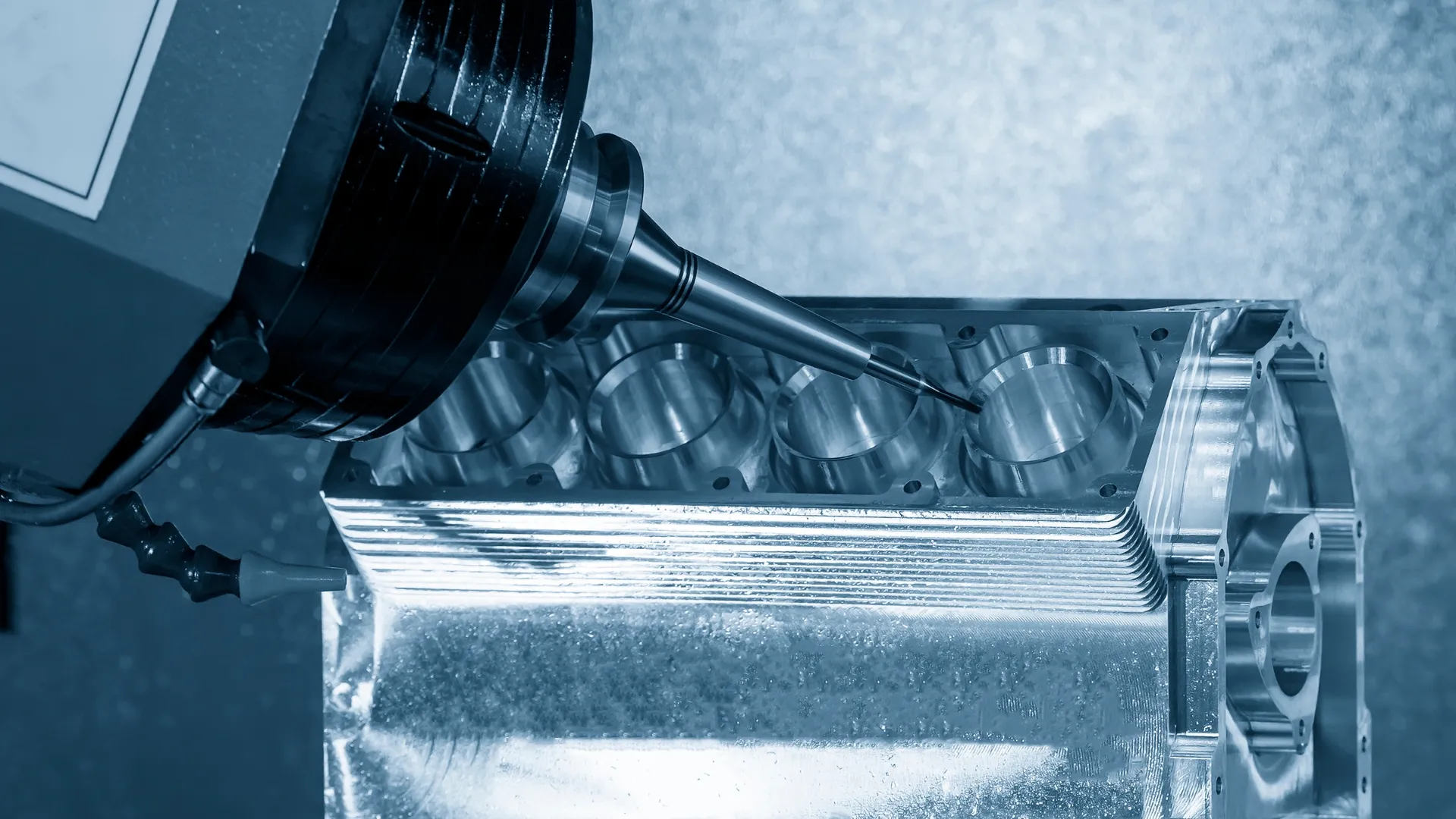

Full-Axis Capability

3/4/5-axis CNC + 50+ machines handling complex geometries with ±0.05mm precision.

All-in-One Solution

From CAD to shipment: CNC, sheet metal, casting & finishing in single workflow.

Mass-Production Ready

30k+ monthly capacity with ISO-certified QC ensuring batch consistency.

Direct Factory Pricing

Competitive rates, no middleman, door-to-door export documentation.

Experiencia en materiales

Free material selection guidance with 30+ alloy options and surface simulations.

Scalable Flexibility

Seamless transition from 5pcs prototyping to 50k batches without compromise.

Más acerca de HDC

See our production facilities and equipment portfolio supporting tight tolerance machining.

| Tipo de equipo | Cantidad | Marca | Travels (mm) |

|---|---|---|---|

| Centro de mecanizado de 5 ejes | 4 | HAAS, BAOFENG | 770×480 – 1270×508 |

| Centro de mecanizado de 4 ejes | 15 | BAOFENG | 500×400 – 700×500 |

| Centro de mecanizado de 3 ejes | 23 | BAOFENG, FRANK | 600×400 – 800×500 |

| Torno CNC | 15 | BOCHI, GAVGOL | Ø1000 × 500 |

| Corte de alambre-electrodo | 1 | – | – |

| Máquina dobladora de tubos CNC | 1 | – | – |

| Desbarbadora vibratoria | 2 | – | – |

| Máquina de soldar | 3 | – | – |

| Máquina de medición por coordenadas | 1 | Sereín | – |

| Probador de dureza Rockwell | 1 | Huayín | – |

| Probador de rugosidad superficial | 1 | Mitutoyo | – |

| Medidor de altura | 2 | Mitutoyo | – |

| Medidor de profundidad | 2 | Mitutoyo | – |

Benefits of CNC Aluminum

Aluminum alloy is widely used in CNC machining due to its lightweight nature, excellent machinability, and favorable strength-to-weight ratio.

These materials deliver high dimensional stability during cutting, resist tool wear, and enable complex geometries with tight tolerances.

Their natural corrosion resistance and compatibility with surface treatments (e.g., anodizing) further expand design possibilities across industries.

Key Aluminum Alloys Comparison

| Parámetro | 6061-T6 | 7075-T6 | 2024-T3 | 5052-H32 |

|---|---|---|---|---|

| Resistencia a la fluencia (MPa) | 275 | 505 | 325 | 195 |

| Dureza (Brinell) | 95 | 150 | 120 | 60 |

| Densidad (g/cm³) | 2.70 | 2.81 | 2.78 | 2.68 |

| Resistencia a la corrosión | Excelente | Moderado | Pobre | Pendiente |

| Machinability Rating | Very Easy | Moderately Difficult | Fácil | Very Easy |

| Costo relativo | Bajo | Muy alto | Alto | Medio |

| soldabilidad | Bien | Pobre | Pobre | Excelente |

Preguntas más frecuentes

Get answers for commonly asked questions before requesting a quote.

We machine all common grades (e.g., 6061, 7075, 2024, 5052) and can advise on the best choice for your part's function, strength, and budget.

We accept STEP, IGES, X_T, STL, or DXF files. 2D drawings (PDF/DWG) are also helpful. Don't have files? Contact us – our engineers can help.

Yes. If you have an idea or sketch but no final design, our engineering team can assist in optimizing it for manufacturability and cost.

We offer a range: as-machined, bead blasting, anodizing (Type II & III - clear/color/hardcoat), powder coating, painting, and polishing. Ask us for recommendations.

Absolutely. Our advanced 3,4 & 5-axis CNC machines and in-house capabilities (like finishing) allow efficient production from 1 piece to 10,000+ units with consistent quality.

Yes. We offer a full range of in-house services: sheet metal fabrication, welding, finishing (anodizing, painting, etc.), and assembly for complete part solutions.

Lead times vary based on complexity and quantity. Prototypes often ship in days; production runs take weeks. We provide an estimated timeline with every quote.

Yes, we ship globally daily. We have extensive experience with international logistics and can provide necessary documentation (commercial invoice, packing list) to simplify customs clearance for you.

We specialize in custom parts. Our MOQ is typically 1 piece for prototyping and low-volume needs. For production runs, MOQs depend on part complexity and setup.

Solicitar presupuesto gratuito

Upload your files for an instant quote and competitive pricing within 24 hours.

Other Resources

Servicio de doblado de metales

Home High-Quality, Custom Metal Bending Solutions Precision Sheet Metal Bending...

Servicio de creación rápida de prototipos

Inicio Acelere el desarrollo de su producto con precisión y velocidad Rápida...

Servicio de mecanizado CNC de 5 ejes

Home Advanced Precision Machining for Complex Components HDC 5 Axis...

Servicio de fundición de inversión de acero inoxidable

Inicio Calidad inigualable, adaptada a sus necesidades Acero inoxidable de alta precisión...