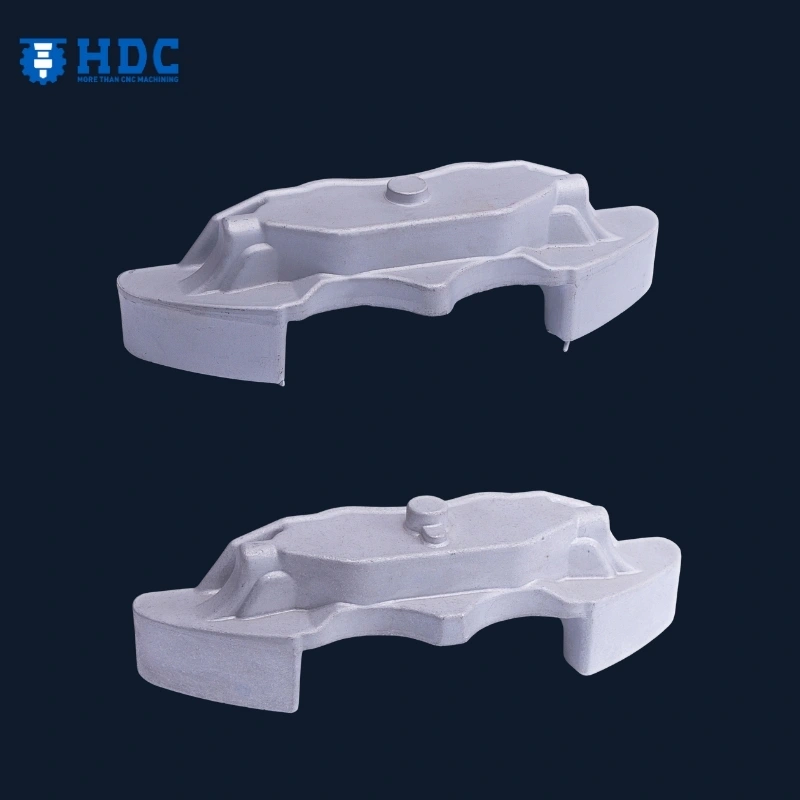

Mangueta de dirección de automóvil forjada en caliente de aleación de acero

Detalles del producto personalizado

| N º de Modelo. | HDCASK001 |

| Estilo | Muñón de dirección |

| Material | Aleación de acero, aluminio, aleación de aluminio |

| Tipo de acabado | Sin acabado, anodizado, recubierto electroforéticamente, recubierto con pintura en polvo, galvanizado, cromado, oxidado negro |

| Talla disponible | / |

| Cantidad mínima de pedido | 100 piezas |

| Logotipo personalizado | Disponible |

| Origen | Porcelana |

| Empaquetado y entrega | |

| Opción de envío | Mensajería, aire, mar, ferrocarril expreso, EXW, FOB, CIF, DDU, DDP |

| Fecha de entrega | 25-30 días |

| Paquete de transporte | Personalizado, Cartón, Palet |

Achieve superior steering precision and long-term suspension reliability with this hot-forged steering knuckle. Precision-engineered as a direct OEM replacement, this component restores factory geometry while offering material flexibility to match your performance priorities—whether structural steel robustness or lightweight aluminum agility.

Dual-Material Forged Construction: Available in high-strength steel alloy for maximum load-bearing durability, or lightweight forged aluminum for significant unsprung mass reduction—both precision hot-forged to optimize grain flow along critical stress paths.

Geometry-Perfect Forging Process: Precision die-forging ensures exact dimensional replication of OEM specifications, preserving factory Ackermann angles, scrub radius, and suspension kinematics without modification.

Enhanced Steering Response: Reduced knuckle mass (aluminum variant) lowers rotational inertia at the wheel hub, sharpening initial turn-in and improving steering feedback fidelity.

Handling Stability Under Load: Forged structural rigidity minimizes deflection during hard braking and cornering, maintaining consistent camber and toe retention for predictable chassis behavior.

Direct Bolt-In Replacement: CNC-machined mounting interfaces replicate original equipment tolerances, ensuring seamless integration with existing wheel bearings, ball joints, and tie rod ends.

Aplicaciones:

OEM Suspension Restoration: Essential for vehicles with worn, corroded, or damaged knuckles requiring factory-spec geometry and mounting accuracy.

Weight Reduction Upgrades: Aluminum forging option ideal for performance builds targeting reduced unsprung mass without compromising structural integrity.

Chassis Reinforcement: Steel forging variant suited for heavy-duty applications, towing packages, or vehicles operating in severe road conditions.

More than a steering pivot, this forged knuckle is the calibrated interface between wheel assembly and chassis—preserving geometry, transmitting feedback, and anchoring suspension kinematics with every revolution. Whether you’re restoring a daily driver or refining a corner-carving platform, it’s the unseen foundation of steering confidence.