Pieza de fundición a la cera perdida Soporte de esquina en forma de L Soporte de esquina en ángulo

Detalles del producto personalizado

| N º de Modelo. | HDCICB001 |

| Estilo | Soporte de esquina en L de fundición de inversión |

| Material | Aluminio, aleación de aluminio, acero, acero inoxidable, superaleación, latón |

| Tipo de acabado | Sin acabado, pulido, anodizado, recubierto electroforéticamente, recubierto con pintura en polvo, galvanizado, cromado, oxidado negro |

| Talla disponible | / |

| Cantidad mínima de pedido 5 | 50 piezas |

| Logotipo personalizado | Disponible |

| Origen | Porcelana |

| Empaquetado y entrega | |

| Opción de envío | Mensajería, aire, mar, ferrocarril expreso, EXW, FOB, CIF, DDU, DDP |

| Fecha de entrega | 25-30 días |

| Paquete de transporte | Personalizado, Cartón, Palet |

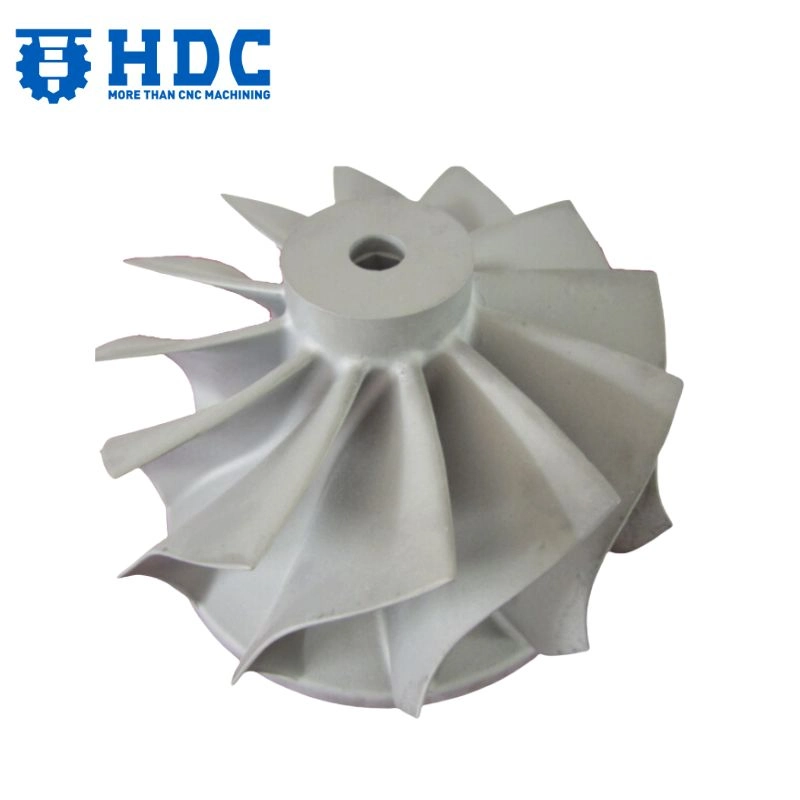

Reinforce the critical junctions of your structural framework with this lost wax cast L-corner bracket. Precision-engineered for applications demanding intricate geometry, material-specific performance, and impeccable surface fidelity, this component consolidates right-angle support into a single, seamless casting—delivered with the design freedom and dimensional accuracy only investment casting can provide.

Multi-Alloy Material Versatility: Available in lightweight aluminum, corrosion-resistant stainless steel, high-temperature superalloy, or durable brass—each precision-selected to match specific load requirements, environmental exposure, and aesthetic or functional objectives.

Lost Wax Cast Geometric Freedom: Precision investment casting enables the formation of complex ribbed profiles, variable wall thicknesses, integrated mounting bosses, and blended fillet radii unattainable through conventional bending, welding, or machining—eliminating stress-prone joints and secondary assembly.

Fine Surface Detail & Dimensional Accuracy: Near-net-shape casting delivers exceptional surface finish and sharp edge definition, reducing or eliminating secondary finishing operations while maintaining exacting hole-to-hole spacing and angular tolerances.

Application-Optimized Material Properties: Alloy-specific heat treatments and passivation processes ensure verified yield strength, corrosion resistance, or thermal stability—tailored to the demands of lightweight structural, marine, or high-temperature framing systems.

Fully Customizable Configuration: Manufactured to customer-specific leg lengths, mounting hole patterns, reinforcement geometry, and thickness profiles—accommodating everything from high-volume OEM component integration to bespoke architectural or industrial framing solutions.

Corrosion-Resistant & High-Temperature Capability: Stainless steel and brass variants deliver exceptional resistance to moisture and chemical exposure; superalloy execution maintains structural integrity in continuous high-temperature operating environments.

Aplicaciones:

Structural Framing & Support Systems: Ideal for equipment enclosures, machine bases, conveyor framing, and modular industrial structures requiring clean, rigid right-angle connections.

Lightweight Aerospace & Automotive: Suitable for interior bracketry, non-structural supports, and cosmetic trim components demanding mass reduction without sacrificing corrosion resistance.

Marine & Offshore Hardware: Essential for saltwater-exposed railing systems, hatch supports, and deck equipment requiring galvanic compatibility and long-term atmospheric durability.

High-Temperature Industrial Fixturing: Engineered for furnace components, exhaust supports, and thermal processing frames requiring verified creep resistance and oxidation stability.

Architectural & Decorative Metalwork: Ideal for custom railings, furniture framing, and ornamental brackets requiring sharp detail, uniform finish, and material authenticity.

More than a simple corner brace, this lost wax cast bracket is the metallurgical intersection of structural intent and design expression—preserving geometry, distributing load, and elevating the visual coherence of every framed assembly. Whether you’re engineering lightweight transport interiors or saltwater-resistant coastal infrastructure, it’s the component that proves support need not sacrifice sophistication.