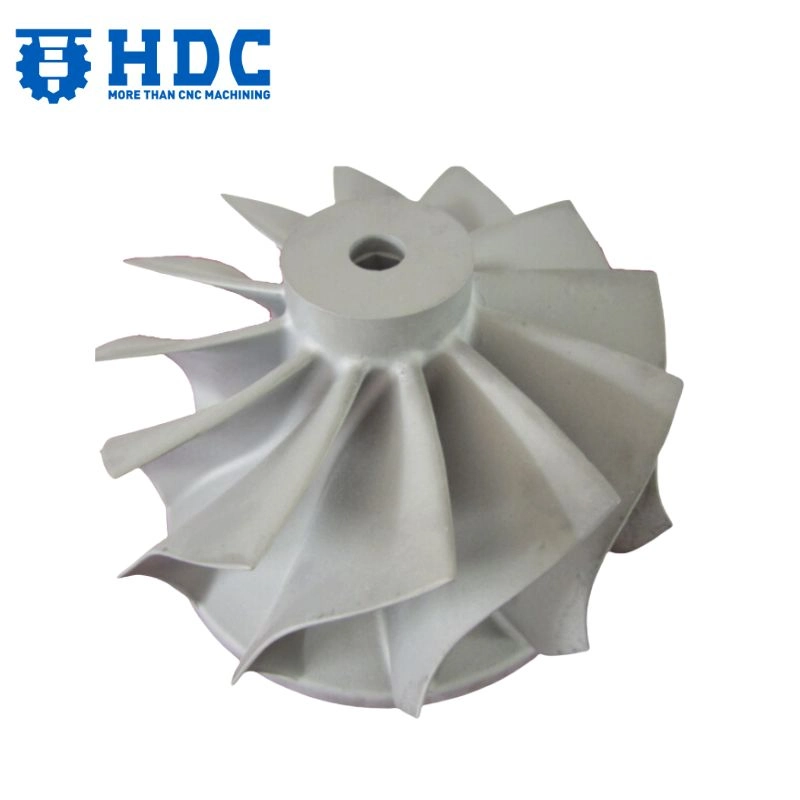

Impulsor de bomba de agua de acero, aluminio, superaleación y latón, pieza de fundición de inversión personalizada

Detalles del producto personalizado

| N º de Modelo. | HDCIPI001 |

| Estilo | Impulsor de bomba de fundición de inversión |

| Material | Aluminio, aleación de aluminio, acero inoxidable, aleación de acero, superaleación, latón |

| Tipo de acabado | Sin acabado, pulido, anodizado, recubierto electroforéticamente, recubierto con pintura en polvo, galvanizado, cromado, oxidado negro |

| Talla disponible | / |

| Cantidad mínima de pedido | 50 piezas |

| Logotipo personalizado | Disponible |

| Origen | Porcelana |

| Empaquetado y entrega | |

| Opción de envío | Mensajería, aire, mar, ferrocarril expreso, EXW, FOB, CIF, DDU, DDP |

| Fecha de entrega | 25-30 días |

| Paquete de transporte | Personalizado, Cartón, Palet |

Consiga una transferencia de fluidos excelente con este impulsor de bomba de agua de fundición a la cera perdida a medida. Diseñado con precisión para sistemas de gestión térmica, circulación y bombeo industrial, este componente ofrece un rendimiento hidráulico constante gracias a la geometría de álabes de fundición integral, con la flexibilidad del material y la continuidad de flujo optimizada que solo la fundición a la cera perdida puede ofrecer.

Versatilidad de materiales multialeación:Disponible en acero de alta resistencia, aluminio liviano, superaleación avanzada o latón resistente a la corrosión, cada uno seleccionado con precisión para adaptarse a temperaturas de fluidos específicos, clasificaciones de presión, compatibilidad química y objetivos de reducción de peso.

Geometría compleja de palas fundidas a la cera perdidaLa fundición de precisión permite la formación de álabes con contornos intrincados, perfiles de espesor variable y bordes de ataque y de salida combinados que no se pueden lograr mediante mecanizado convencional o conjuntos fabricados, lo que preserva la intención aerodinámica/hidráulica sin comprometerla.

Integridad estructural monobloque:La construcción de una sola pieza, fundida integralmente, elimina las uniones soldadas, las costuras soldadas y los sujetadores mecánicos, eliminando los posibles puntos de falla y manteniendo las propiedades continuas del material desde el ojo hasta la cubierta.

Pasajes de flujo suaves y sin restriccionesLos acabados superficiales fundidos y la geometría optimizada del canal entre álabes minimizan las pérdidas por fricción, reducen el potencial de cavitación y mantienen las características de flujo laminar en todo el rango operativo.

Excelente equilibrio dinámicoLa precisión de fundición de forma cercana a la neta combinada con el balanceo CNC de precisión garantiza una rotación concéntrica, un paso de paletas constante y una vibración mínima, lo que extiende la vida útil del sello y reduce el desgaste de los cojinetes en aplicaciones de servicio continuo.

Perfil hidráulico totalmente personalizableFabricados según los requisitos de cantidad de paletas, diámetros de salida, configuraciones de cubo y caudal específicos del cliente, se adaptan a todo, desde refrigeración automotriz de gran volumen hasta circulación de procesos industriales de servicio pesado.

Ingeniería de superficies optimizada para aplicaciones:Disponible con recubrimientos cerámicos opcionales, revestimientos resistentes a la erosión o tratamientos de pasivación química, lo que proporciona protección duradera contra partículas abrasivas, daños por cavitación y medios fluidos agresivos.

Aplicaciones:

Refrigeración de motores automotrices:Ideal para bombas de agua, circulación eléctrica auxiliar y sistemas de gestión térmica híbridos que requieren un empaque compacto y una consistencia de flujo sostenida.

Circulación de procesos industriales:Esencial para torres de enfriamiento, enfriadores HVAC, sistemas de alimentación de calderas y aplicaciones de transferencia química que exigen resistencia a la corrosión verificada y eficiencia hidráulica.

Bombeo marino y en alta mar:Adecuado para refrigeración de motores con agua cruda, transferencia de lastre y sistemas de lavado de cubierta que requieren compatibilidad galvánica y durabilidad en agua salada.

Riego y transferencia agrícola:Diseñado para sistemas de pivote central, abrevaderos de ganado y equipos de pulverización de cultivos que requieren un rendimiento resistente a la abrasión en fluidos cargados de partículas.

Sistemas de manejo de fluidos personalizados:Ideal para el desarrollo de prototipos, construcción de vehículos especiales y aplicaciones industriales únicas que requieren una geometría de impulsor no estándar con caracterización de flujo certificada.

Más que un componente rotatorio, este impulsor de fundición de precisión es la conciencia hidráulica de su sistema de fluidos, transformando la energía rotacional en un caudal medido con precisión en cada revolución, temporada tras temporada. Ya sea que esté diseñando la arquitectura térmica de vehículos eléctricos de última generación o la infraestructura de control de inundaciones de la industria pesada, es el componente que demuestra que la eficiencia de bombeo comienza con la continuidad monobloque de fundición de precisión.