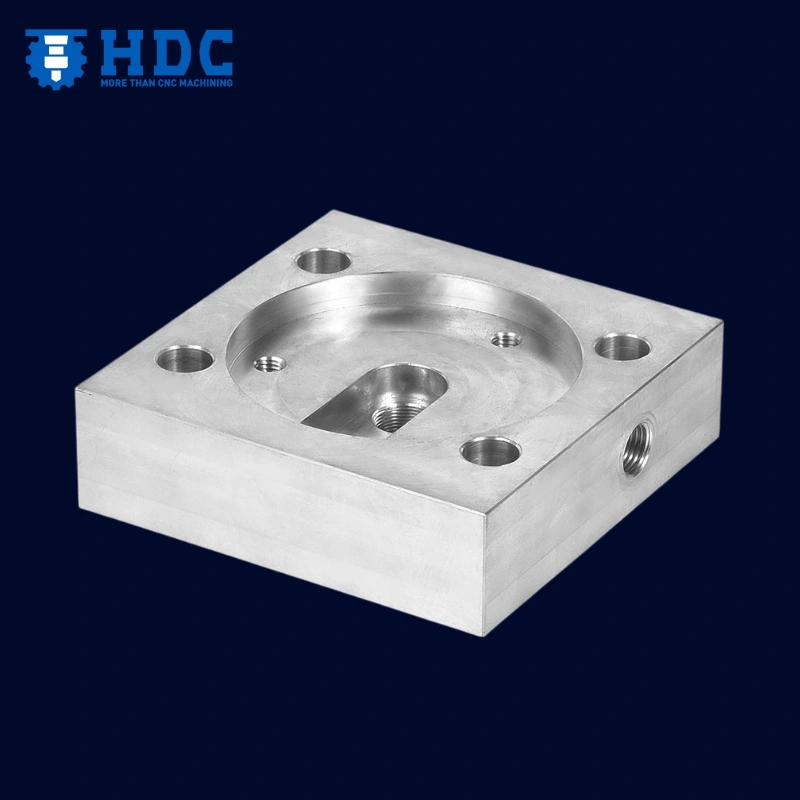

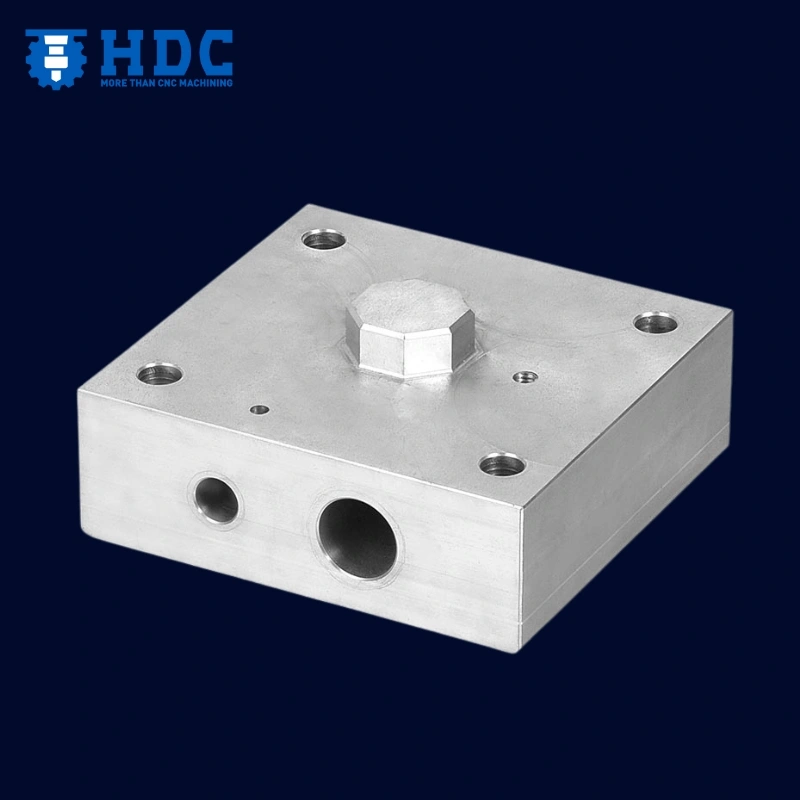

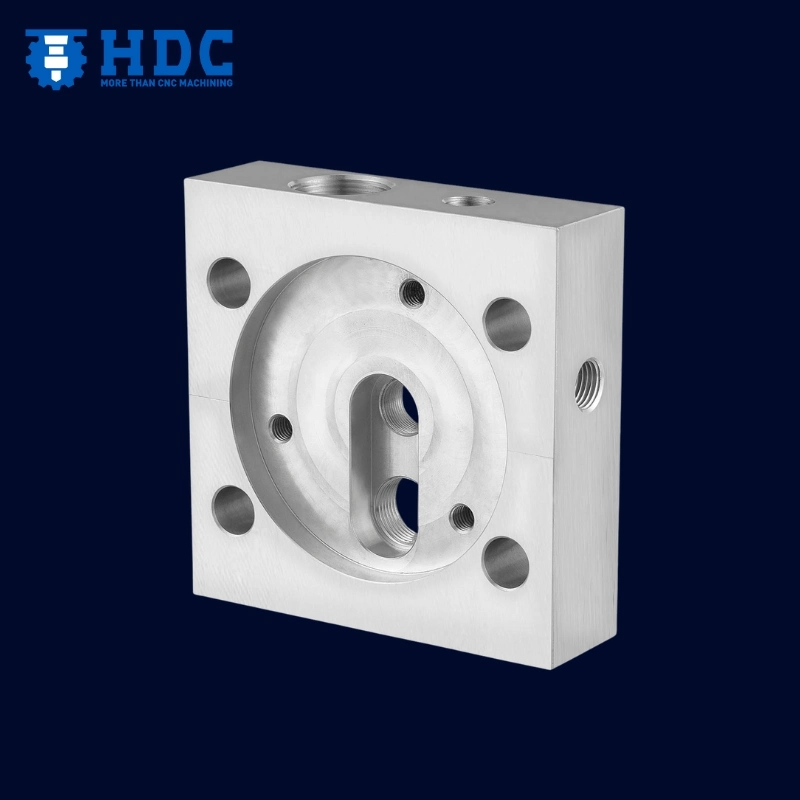

Bloque de válvulas de colector hidráulico de aluminio forjado en caliente de precisión con mecanizado CNC

Detalles del producto personalizado

| N º de Modelo. | HDCFVB002 |

| Estilo | Cuerpo de válvula forjado |

| Material | Aluminio, aleación de aluminio, acero, aleación de acero |

| Tipo de acabado | Sin terminar, pulido, anodizado, con recubrimiento electroforético, con recubrimiento en polvo, galvanizado, cromado, con óxido negro |

| Talla disponible | / |

| Cantidad mínima de pedido | 100 piezas |

| Logotipo personalizado | Disponible |

| Origen | Porcelana |

| Empaquetado y entrega | |

| Opción de envío | Mensajería, aire, mar, ferrocarril expreso, EXW, FOB, CIF, DDU, DDP |

| Fecha de entrega | 25-30 días |

| Paquete de transporte | Personalizado, Cartón, Palet |

Controle la vitalidad de su sistema hidráulico con este bloque colector de aluminio forjado en caliente con precisión. Diseñado con precisión para maquinaria industrial y equipos móviles que exigen una eficiencia de flujo, integridad de presión y consolidación espacial inquebrantables, este componente transforma las redes de fluidos caóticas en una transmisión de potencia organizada y de alta velocidad, con la integridad de flujo de grano que solo la forja de grado aeroespacial puede proporcionar.

Cimentación de aluminio de grado aeroespacial:Forjado en caliente a partir de una aleación de aluminio de primera calidad con certificación aeroespacial, logrando una orientación de grano unidireccional y continua a lo largo de las trayectorias de presión primaria para una resistencia a la fatiga excepcional y una rigidez estructural optimizada en términos de peso.

Geometría de paso totalmente mecanizada por CNC:Todos los canales de fluido, interfaces de puertos y superficies de montaje están mecanizados con CNC de 5 ejes con tolerancias micrométricas, lo que garantiza intersecciones de pasos precisas, cero fugas entre puertos y contención de presión verificada según las especificaciones nominales.

Arquitectura de flujo interno optimizada por CFDLas geometrías de canales internos diseñadas computacionalmente presentan transiciones de radio suaves, ángulos de curvatura optimizados y zonas de turbulencia minimizadas, lo que proporciona una transmisión de flujo eficiente con menor caída de presión y generación de calor.

Fortificación de superficies anticorrosión:Disponible en anodizado duro, niquelado químico o recubrimientos industriales especializados, que brindan protección duradera contra la degradación del fluido hidráulico, la exposición atmosférica y la incompatibilidad galvánica.

Configuración de puerto totalmente personalizable:Fabricados según cantidades de puertos, tipos de roscas (SAE, BSP, NPT, métricos), patrones de montaje de válvulas y clasificaciones de presión específicos del cliente, adaptándose a todo, desde sistemas hidráulicos móviles compactos hasta unidades de energía industriales de alto flujo.

Arquitectura de sistema consolidada:Integra múltiples funciones de válvula, puertos de sensores y pasajes de control de flujo en un solo cuerpo forjado sin fugas, eliminando docenas de accesorios separados, reduciendo posibles rutas de fuga y simplificando el mantenimiento del sistema.

Aplicaciones:

Unidades de potencia hidráulicas industriales:Ideal para controles de prensa, máquinas de moldeo por inyección y sistemas de manipulación de materiales que requieren integridad de presión verificada y servicio sin fugas a largo plazo.

Equipos móviles y todoterreno:Esencial para excavadoras, cargadoras, maquinaria agrícola y manipuladores telescópicos que operan en entornos con mucha vibración y con estrictas restricciones de peso y embalaje.

Sistemas de energía fluida personalizados:Adecuado para desarrollo de prototipos, construcción de vehículos especiales y celdas de automatización únicas que exigen integración de válvulas no estándar y certificación de flujo verificado.

Hidráulica marina y de alta mar:Diseñado para un rendimiento resistente a la corrosión en aplicaciones de equipos de dirección, cabrestante y cubierta expuestos al agua salada.

Más que un bloque de distribución de fluidos, este colector de aluminio forjado es la red neuronal consolidada de su arquitectura hidráulica: preserva la presión, organiza el flujo y garantiza que cada actuador reciba la energía medida con precisión, exactamente cuando se le ordena. Ya sea que esté reduciendo el tamaño de un paquete de válvulas móviles o diseñando sistemas de energía industrial a prueba de fallos, es el componente que demuestra que la inteligencia hidráulica comienza con un flujo de grano forjado e ininterrumpido y una lógica de paso mecanizada con precisión.