El acetal y el delrin son dos plásticos de ingeniería de uso común que se emplean ampliamente en aplicaciones industriales debido a sus excelentes propiedades mecánicas, resistencia química y facilidad de mecanizado. Si bien ambos materiales pertenecen a la categoría de resinas de acetal, tienen características distintivas que los hacen adecuados para diferentes aplicaciones.

Este artículo explora las claves Diferencias y similitudes entre Acetal y Delrin, analizando su composición, propiedades mecánicas, aplicaciones, ventajas y limitaciones.

¿Qué es el acetal?

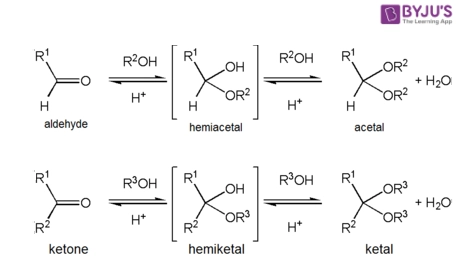

Fuentes: de BYJU

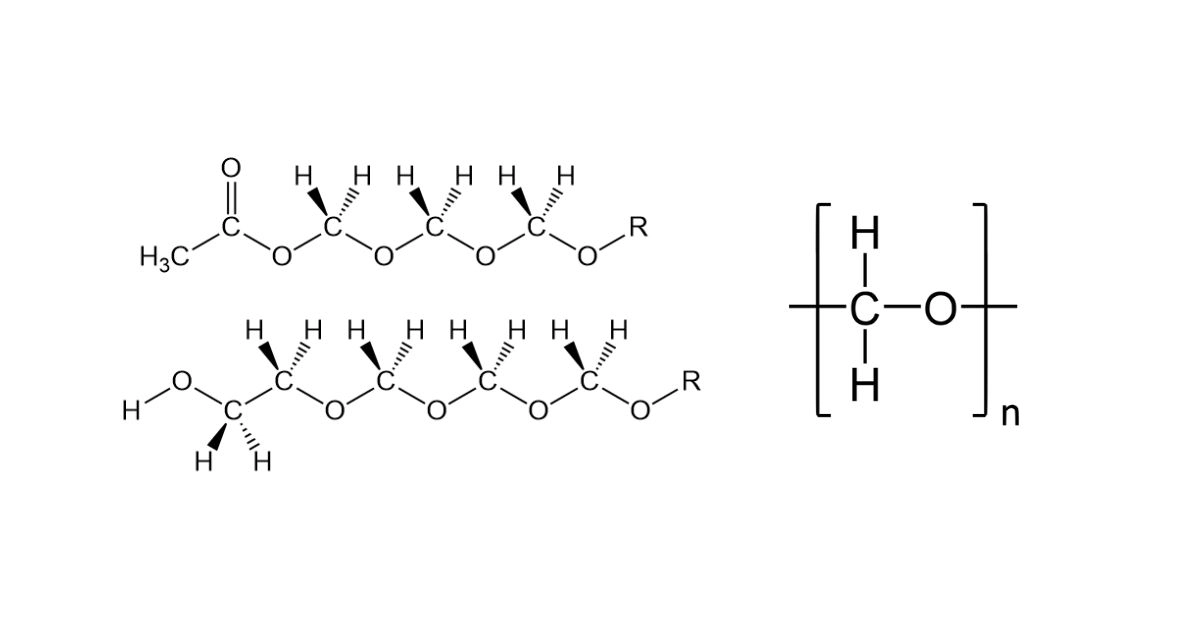

El acetal, también conocido como polioximetileno (POM), es un polímero termoplástico conocido por su alta resistencia, baja fricción y excelente estabilidad dimensional.

Se produce en dos formas principales, a saber: a) Acetal homopolímero – Comercializado bajo la marca Delrín (de DuPont), este tipo tiene una estructura molecular uniforme, ofreciendo propiedades mecánicas superiores y b) Copolímero de acetal – Se vende bajo diversos nombres comerciales (por ejemplo, Celcon, Ultraform, Kepital) y contiene una estructura molecular modificada que mejora ciertas características como la resistencia química y la estabilidad térmica.

El acetal se utiliza ampliamente en componentes mecánicos de precisión debido a su excelente resistencia al desgaste, baja absorción de humedad y capacidad de mantener su forma bajo carga.

¿Qué es Delrin?

Delrin® es un marca específica de homopolímero de acetal (POM, polioximetileno) desarrollado por DuPont. Si bien el Delrin pertenece a la familia más amplia de los acetales, se destaca por su alta cristalinidad, lo que mejora su resistencia, rigidez y resistencia al desgaste.

Características principales de Delrin:

Delrin ofrece Propiedades mecánicas superiores en comparación con los acetales de copolímero, lo que lo convierte en la opción preferida para aplicaciones de alto rendimiento. Mayor resistencia a la tracción y al impacto., lo que le permite soportar tensiones mecánicas significativas sin deformarse.

Además, Delrin tiene Mejor resistencia a la fluencia y a la fatiga., asegurando la durabilidad a largo plazo en componentes sometidos a cargas repetitivas.

Sin embargo, tiene Resistencia química ligeramente menor en comparación con los acetales de copolímero, lo que lo hace menos adecuado para entornos con ácidos fuertes o solventes. A pesar de esto, Delrin Mayor rigidez y dureza Contribuyen a su excelente estabilidad dimensional y resistencia al desgaste, haciéndolo ideal para aplicaciones mecánicas de precisión.

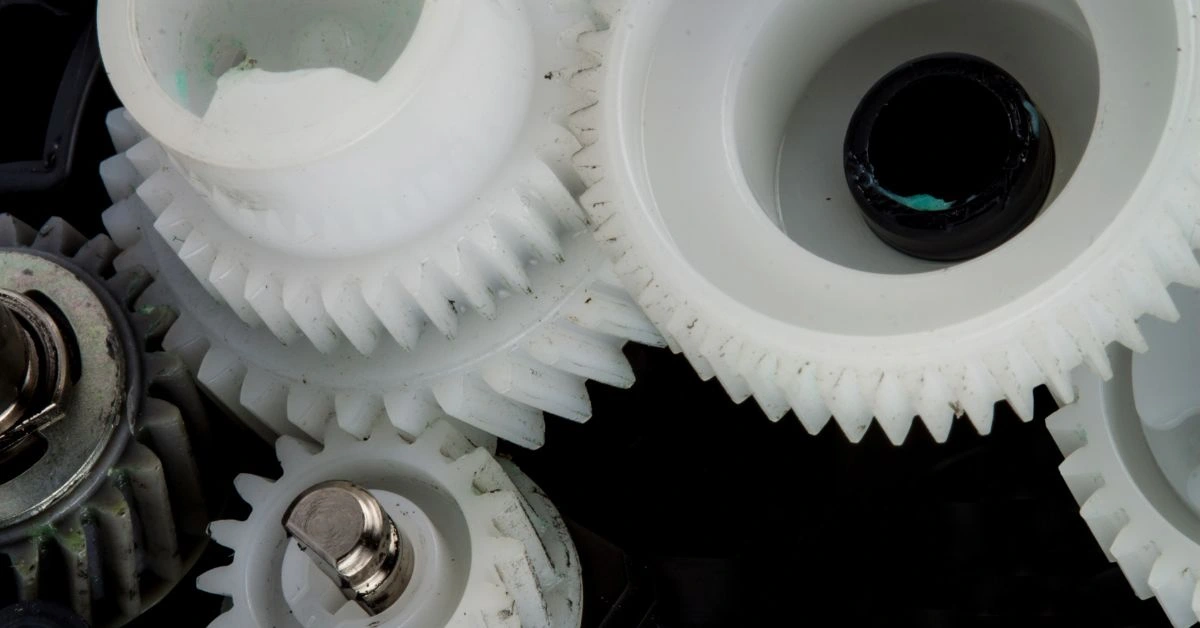

Delrin es particularmente preferido para aplicaciones que requieren alta precisión y durabilidad, como piezas de automóviles, engranajes industriales y componentes mecánicos de alto rendimiento.

Diferencias clave entre acetal y delrin

Aunque Delrin es un tipo de acetal, existen diferencias significativas entre Delrin (acetal homopolímero) y acetato de copolímerol en términos de estructura, propiedades y aplicaciones. El delrin presenta una estructura molecular más uniforme y cristalina, lo que mejora su resistencia mecánica y durabilidad, mientras que el acetal copolímero consiste en una mezcla de diferentes cadenas de polímeros, lo que reduce la cristalinidad pero mejora la resistencia química y la estabilidad térmica.

Propiedades mecánicas

En términos de propiedades mecánicas, Delrin tiene más alto resistencia a la tracción (~11.000 psi) y mayor rigidez, lo que lo hace adecuado para aplicaciones de alta carga. También presenta una resistencia al impacto superior, ideal para componentes dinámicos que experimentan estrés repetido, y ofrece una mejor resistencia a la fatiga en comparación con el acetal copolímero.

Propiedades químicas

La resistencia química del Delrin es menor, ya que es más susceptible a la degradación por ácidos fuertes y agua caliente. Por el contrario, el acetal copolímero ofrece mayor resistencia a ácidos, álcalis y solventes, lo que lo hace preferible para entornos químicos agresivos.

Propiedades termales

En cuanto a las propiedades térmicas, el acetal copolímero es más resistente a la degradación térmica, mientras que el Delrin puede degradarse en condiciones de altas temperaturas o humedad. El Delrin tiene un punto de fusión ligeramente más alto (~175 °C frente a ~165 °C), lo que proporciona un mejor rendimiento en aplicaciones expuestas al calor.

Absorción de humedad

La absorción de humedad es otro factor diferenciador: el Delrin absorbe un poco más de humedad (~0,25%) que el acetal copolímero (~0,20%), lo que puede generar inestabilidad dimensional en entornos húmedos. Por otro lado, el acetal copolímero conserva su forma de manera más eficaz en tales condiciones.

Por último, el Delrin suele ser más caro debido a sus propiedades mecánicas superiores y su marca, mientras que el acetal copolímero es más rentable y está ampliamente disponible, lo que lo convierte en la opción preferida para aplicaciones sensibles al presupuesto.

Aplicaciones de acetal frente a delrin

Tanto el acetal como el delrin se utilizan en diversas industrias debido a su resistencia, durabilidad y maquinabilidad. Sin embargo, sus diferencias en propiedades los hacen más adecuados para aplicaciones específicas.

Aplicaciones comunes de Delrin (acetal homopolímero):

Delrin se utiliza ampliamente en diversas industrias debido a sus propiedades mecánicas superiores y su durabilidad.

En el sector automovilístico sector, se encuentra comúnmente en engranajes, combustible sistema regiones, y asiento cinturón componentes, donde la resistencia y la resistencia al desgaste son cruciales.

En maquinaria industrial, Delrin se utiliza para engranajes de precisión, rodillos transportadores y componentes de bombas, lo que garantiza un funcionamiento suave y una confiabilidad a largo plazo.

El campo médico también se beneficia de las propiedades del Delrin, ya que se utiliza en inhaladores, dispositivos protésicos e instrumentos quirúrgicos, donde la precisión y la biocompatibilidad son esenciales.

Además, en bienes de consumoDelrin es un material preferido para Sujetadores de alta gama, mangos de cuchillos y componentes de armas de fuego, ofreciendo resistencia, durabilidad y resistencia al desgaste y al impacto.

Aplicaciones comunes del copolímero acetal:

El acetal copolímero se utiliza ampliamente en diversas industrias debido a su excelente resistencia química y estabilidad dimensional.

En equipos de procesamiento químico, es ideal para bombas, sellos y componentes de válvulas., ya que puede soportar ambientes corrosivos.

La industria de alimentos y bebidas también confía en el acetal de copolímero para cintas transportadoras de alimentos y piezas de procesamiento de productos lácteos que cumplen con la FDA., Garantizar la seguridad y la higiene.

En Aplicaciones eléctricas, se utiliza para aisladores, carcasas y componentes de interruptores., gracias a sus excelentes propiedades dieléctricas y durabilidad.

Además, en aplicaciones marinas, El acetal copolímero se prefiere para las piezas de las embarcaciones debido a su Resistencia superior al agua, lo que lo hace muy adecuado para la exposición prolongada a la humedad y a condiciones ambientales adversas.

Conclusión

Ambos Acetal (POM) y Delrin son plásticos de ingeniería muy valiosos con propiedades superpuestas pero distintas. Delrín (homopolímero) sobresale en Resistencia mecánica, resistencia al desgaste y precisión., acetal copolímero proporciona Mejor resistencia química y térmica. a un coste menor.

En HDC contamos con profesionales minuciosos que pueden guiarlo en la selección del mejor material para su aplicación.

Descubra más con nuestras publicaciones de blog.

Mensajes recientes

Descubra más sobre nuestros productos.

Productos relacionados

¡Cotización instantánea!