Titanio vs. aluminio: una de las comparaciones más comunes debido a la calidad de ambos. Sin embargo, son muy diferentes y, francamente, tienen sus mejores usos.

Entonces, en este blog, responderemos las preguntas más comunes relacionadas con estas comparaciones, como, por ejemplo, si el titanio es más fuerte que el aluminio, cuál es más liviano y muchas más.

Entendiendo el aluminio

Aluminio Es un metal ligero y versátil ampliamente utilizado en diversas industrias debido a sus propiedades únicas.

Cuenta con una excelente resistencia a la corrosión, alta conductividad térmica y baja densidad, lo que lo hace ideal para aplicaciones donde la reducción de peso es crucial, como en las industrias automotriz y aeroespacial.

El aluminio también es muy maleable, lo que permite a los fabricantes crear formas y figuras complejas.

Entendiendo el titanio

En el otro extremo de la cuerda, titanio Este metal de alto rendimiento es conocido por su excepcional relación resistencia-peso y resistencia a la corrosión.

Es significativamente más ligero que el acero, pero igual de resistente. Esto lo hace ideal para industrias como la aeroespacial, la de dispositivos médicos y la marina.

El titanio resiste naturalmente la oxidación, el deslustre y los daños químicos, incluso en entornos hostiles como el agua salada o temperaturas extremas. Además, su alto punto de fusión aumenta su durabilidad en condiciones exigentes.

Titanio vs. Aluminio: ¿Cuál se adapta mejor?

Fuente: Fabricación Aria

Comparar el aluminio y el titanio implica más que simplemente observarlos uno al lado del otro. Para comprender completamente sus diferencias, debemos analizar cada factor y analizarlo por separado.

Peso del titanio frente al aluminio

A la hora de determinar el peso, el aluminio es más ligero debido a su densidad de 2,7 g/cm³ en comparación con los 4,5 g/cm³ del titanio (aproximadamente).

Puede que no parezca mucho, pero esta diferencia es uno de los principales factores que los distinguen. Además, esto convierte al aluminio en una mejor opción para aplicaciones en las industrias automotriz y aeroespacial, donde el peso es crucial.

¿Es el titanio más ligero que el aluminio? ¡No lo es!

Comparación de fuerza

Sin embargo, en términos de resistencia, el titanio se lleva la palma. En comparación con el aluminio, el titanio tiene una relación resistencia-peso considerablemente mayor.

Esto significa que el titanio puede ofrecer mayor resistencia para una cantidad determinada de material. Esta ventaja es especialmente útil en sectores como el aeroespacial y el médico, que requieren materiales resistentes y ligeros.

El titanio es el material recomendado por su durabilidad en entornos hostiles, aunque el aluminio es más liviano y frecuentemente menos costoso.

Comparación de la resistencia a la corrosión

Cuando se comparan el titanio y el aluminio en cuanto a resistencia a la corrosión, el titanio generalmente tiene un mejor desempeño.

Debido a su excepcional resistencia a la corrosión, el titanio es perfecto para aplicaciones que están sujetas a condiciones adversas y humedad.

El aluminio, por otro lado, es más propenso al deterioro en ambientes hostiles, aunque forma naturalmente una capa de óxido protectora que proporciona cierta resistencia a la corrosión.

Conductividad del titanio frente a la del aluminio

El aluminio supera significativamente al titanio en cuanto a conductividad eléctrica. Es reconocido como uno de los metales más conductores del mundo.

De hecho, se utiliza ampliamente en aplicaciones eléctricas, como cableado, líneas eléctricas y componentes que requieren una transferencia de energía eficiente.

Su conductividad es aproximadamente 37,7 millones de siemens por metro (MS/m), lo que lo hace muy eficiente para transmitir electricidad con una resistencia mínima, en comparación con el titanio. 2,38 MS/m.

Precio del titanio frente al aluminio

¿Cuál crees que es más caro? El aluminio es significativamente más barato que el titanio, lo que lo convierte en una opción más económica.

Hoy en día, el aluminio cuesta aproximadamente entre $1 y $1,50 por libra, dependiendo de las condiciones del mercado y el grado.

Por el contrario, el titanio es mucho más caro, con un promedio de $25 a $35 por libra para material de calidad comercial, en gran medida debido a sus complejos requisitos de extracción y procesamiento.

NOTA: Debido a esto, muchos encuentran diferentes formas de encontrar lagunas en la sustitución del titanio por aluminio porque es más barato.

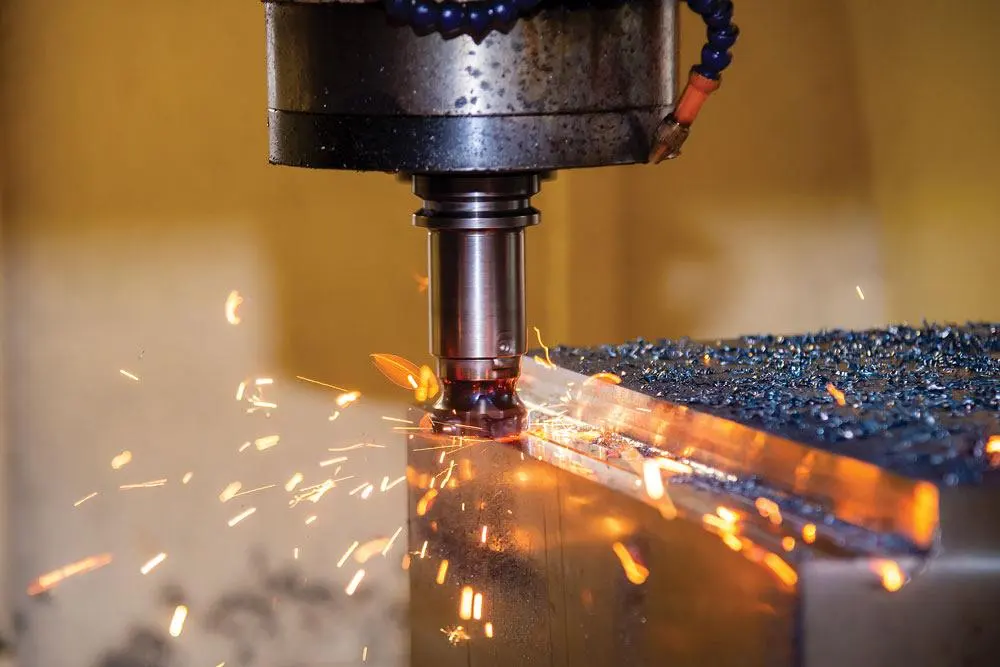

Maquinabilidad del aluminio y el titanio

Fuente: Metalurgia canadiense

El aluminio es conocido por su excelente maquinabilidad, lo que lo convierte en un material predilecto para muchas industrias. Su baja densidad y blandura permiten velocidades de corte más rápidas y un menor desgaste de las herramientas.

Por otro lado, el titanio presenta considerables dificultades de mecanizado. El desgaste de la herramienta se acelera por la rápida acumulación de calor en el punto de corte, causada por su resistencia y baja conductividad térmica.

A menudo se necesitan mayores fuerzas de corte, velocidades más lentas y herramientas de corte y lubricantes especializados para realizar el trabajo.

Aplicaciones del aluminio y el titanio

Y, por supuesto, no olvidemos las aplicaciones y usos de cada uno de estos metales. Analicemos con más detalle cada una de sus aplicaciones y las industrias con las que trabajan.

Aplicaciones del aluminio

El aluminio se utiliza ampliamente en numerosas industrias gracias a su ligereza, sus propiedades resistentes a la corrosión y su facilidad de maquinabilidad.

Industria automotriz

El aluminio ayuda a mejorar la eficiencia del combustible al reducir el peso del vehículo y mantener su resistencia. Se utiliza comúnmente en componentes de motor, paneles de carrocería y ruedas.

Industria aeroespacial

En la industria aeroespacial, por el contrario, constituyen un porcentaje significativo de las estructuras de las aeronaves, incluidas las alas y los fuselajes, debido a su naturaleza ahorradora de peso y resistente a las tensiones.

Fuente: Metales Sunrise

Industria de construccion

La industria de la ingeniería y la construcción también se beneficia del aluminio en marcos de ventanas, puertas y materiales para techos, ofreciendo tanto durabilidad como atractivo estético.

Industria electrónica

Y, por último, la industria electrónica: hablemos de carcasas para portátiles y teléfonos, disipadores de calor y aplicaciones más cruciales.

Aplicaciones del titanio

¡Ahora vamos a discutir las diferentes aplicaciones del titanio!

Aeroespacial

Las aleaciones de titanio son esenciales para componentes como motores de turbinas, bastidores y trenes de aterrizaje debido a su alta resistencia y capacidad para soportar altas temperaturas sin comprometer el peso.

Energía

Para esta industria, las aplicaciones, particularmente en los sectores de petróleo y gas, aprovechan el titanio para tuberías y equipos de perforación debido a su durabilidad en condiciones difíciles.

Marina

Debido a que el titanio resiste la corrosión mejor que la mayoría de los otros metales, también se utiliza en la industria marina para piezas que están expuestas al agua salada.

Médico

No olvidemos el sector médico. Dependen en gran medida del titanio para implantes, como los reemplazos articulares, debido a su biocompatibilidad y resistencia a la corrosión en el cuerpo humano.

¡Y ahí lo tienen! Las diferentes aplicaciones del titanio y el aluminio, aclarando la diferencia entre ellos.

Con base en estas comparaciones, ¿qué cree que funcionaría mejor para su proyecto? ¿Qué le daría los mejores resultados, garantizando al mismo tiempo la rentabilidad y la eficiencia?

Tabla comparativa de titanio y aluminio

Puede ser mucha información, lo cual es lógico considerando lo diferentes que son. Pero estamos aquí para ayudarte. Por eso, hemos preparado una tabla sencilla para que veas rápidamente las diferencias entre el aluminio y el titanio.

¡Esta tabla captura las diferencias principales entre ambos y las explica con más detalle!

| Aspecto | Titanio | Aluminio |

| Peso | Más pesado que el aluminio, pero ofrece una resistencia excepcional para su peso. | Ligero y preferido en aplicaciones donde minimizar el peso es fundamental. |

| Fuerza | Ofrece una relación resistencia-peso superior, lo que lo hace ideal para usos aeroespaciales y militares. | Resistencia adecuada para la mayoría de aplicaciones, pero inferior en comparación con el titanio. |

| Resistencia a la corrosión | Altamente resistente al óxido y a la corrosión, incluso en ambientes marinos y agresivos. | Resiste bien la corrosión pero es más propenso a la oxidación en condiciones adversas. |

| maquinabilidad | Es un reto para la máquina, ya que requiere velocidades más lentas y equipos especializados. | Fácil de mecanizar y dar forma con herramientas estándar, lo que hace que su procesamiento sea rentable. |

| Conductividad eléctrica | Mal conductor eléctrico, lo que limita su uso en cableado o componentes conductores. | Excelente conductor eléctrico, ampliamente utilizado en líneas eléctricas y dispositivos electrónicos. |

| Conductividad térmica | Baja conductividad térmica, reteniendo el calor en aplicaciones de alta temperatura. | Alta conductividad térmica, adecuado para disipadores de calor y utensilios de cocina. |

| Punto de fusion | Punto de fusión más alto (1.668 °C), lo que lo hace adecuado para aplicaciones de calor extremo. | Punto de fusión más bajo (660°C), lo que limita su uso en entornos de alta temperatura. |

| Aplicaciones | Se encuentra en la industria aeroespacial, en implantes médicos y en equipos marinos debido a su durabilidad y biocompatibilidad. | Común en piezas de automóviles, construcción, embalajes y productos para el hogar debido a su versatilidad. |

| Costo | Más caro debido a la disponibilidad limitada y a los métodos de procesamiento complejos. | Más asequible y ampliamente disponible, ideal para proyectos sensibles a los costos. |

| Esperanza de vida | Extremadamente duradero, dura décadas en condiciones exigentes. | Durable para aplicaciones diarias pero puede degradarse más rápido en condiciones severas. |

NOTA: ¡Úselo como una hoja de trucos, una tabla simple para un vistazo rápido o como referencia para una presentación o informe!

¡Nuestro objetivo es hacerte la vida más fácil y que puedas encontrar información más rápido!

¿El titanio se raya más fácilmente que el aluminio?

Fuente: Un blog para seguir

La idea general es que el titanio es más blando que el aluminio, pero no, eso es incorrecto. El titanio es más duro y tiene mucha más resistencia a la tracción que el aluminio, por lo que es prácticamente imposible que se raye con más facilidad que el aluminio.

Sin embargo, es importante tener en cuenta que algunas aleaciones de titanio (no puro) pueden ser menos resistentes a los arañazos y daños que el aluminio.

En resumen, el titanio puro es más resistente a los arañazos que el aluminio. Sin embargo, las aleaciones y otros compuestos tienden a rayarse y dañarse más rápidamente que el aluminio.

Get Whatever Metal You Need From HDC Manufacturing

Con la marca #1 como fabricante de piezas y componentes metálicos, ¡puede confiar plenamente en nosotros! Desde 2009, nos hemos centrado en ofrecer piezas y componentes metálicos de la más alta calidad a nuestros clientes.

Ya sea que lo necesitaran aleaciones de titanio, aleaciones de níquel, aluminio, acero inoxidable, o incluso plástica¡Estamos aquí! Si necesita aleación de titanio y aluminio, también puede contar con nosotros.

Nuestra empresa cuenta con algunos de los mejores y más confiables ingenieros y expertos en metales de la industria. Así que, si tiene preguntas sobre el titanio o el aluminio, o si tiene alguna duda sobre lo que recibió, ¡no dude en llamarnos!

Así que, si busca un fabricante en el que pueda confiar indefinidamente, ¡no dude en trabajar con nosotros! ¡Solicite un presupuesto gratuito hoy mismo! Llámenos o envíenos un correo electrónico; estaremos aquí para responderle.