- Maison

- Ressources

- Blog

- Procédé de recuit des métaux

Annealing is usually done after casting, which is one of our core services at HDC. It reduces hardness, improves ductility, and also relieves internal stress in the metal. This ensures the product is ready for long-term performance in various demanding applications.

What is Annealing?

Annealing is a heat treatment process that is used to make metals a lot easier to work with. It is one of the most important heat treatment processes and is essential for other manufacturing steps.

How Annealing Works: Core Mechanisms

Processes like casting or bending can often affect the structure. So, annealing is used to fix these small defects and align the structure. Three key changes happen during this process:

- Atomic Migration: Heat gives the atoms energy, allowing them to move around and rearrange into a more orderly pattern.

- Dislocation Reduction: Dislocations are tiny tangles in the crystal structure that make the metal harder and brittle. During annealing, these tangles are reduced, resulting in a softer metal.

- Microstructural Changes: The small crystals known as grains form and fix the structure of the metal, making it more stable.

Stages of Annealing

Recovery Stage

This first stage happens at lower temperature levels. The process repairs damages within the crystal structure and relieves any internal stress. However, the main properties of the metal do not change much.

Recrystallization Stage

This is when the metal reaches its recrystallization temperature. Newer grains start to appear, replacing the old, damaged ones. This results in a structure with improved flexibility and reduced hardness.

Grain Growth Stage

If the temperature is maintained after recrystallization, new grains start forming. These tiny grains merge to form larger ones, which can make the material much softer. However, this stage needs to be controlled properly, or it could harm other properties.

Situations Where Annealing Can Be Used

Annealing is used to solve common problems when making things from metals.

Reverse Work Hardening

Cold working processes, like rolling or forging, can work-harden metals. Annealing is used to reverse this effect by making the metal soft and workable again for manufacturing processes.

Reduce Weld Solidification

The welding process joins metals with intense heat, and when the metal cools rapidly, it creates a lot of stress in the joint. Annealing helps to remove this stress and prevents cracks from forming.

Enhance Electrical Conductivity

In metals like copper, work hardening can block electricity flow, making the wires less efficient. Annealing smooths out the internal structure, allowing the metal to conduct electricity better.

Remove Residual Stresses

Residual stress from casting or machining can warp the workpiece. With annealing, we make sure the parts are stable and strong for their final use.

Types of Annealing Processes

Stress Relief Annealing

This process lowers the residual stresses without major changes to the strength of the metal. It uses moderate heat for a shorter time, which prevents any distortions during machining. Most times, welded parts benefit from this process.

Isothermal Annealing

This is a specialized process. Here, after the metal is heated, it is cooled to a set temperature. The metal is held at that point to control the transformation. This can speed up production and control the uniformity of steel.

Diffusion Annealing

This is also known as homogenizing. It uses high heat for long periods to help even out chemical differences in alloys. It is usually used in castings with uneven structures. The cooling process must be slow to allow atoms to create a more uniform structure.

Incomplete Annealing

In this process, steel is heated to a temperature that’s just between the lower (Ac1) and upper (Ac3) critical points. This results in partial austenitization and creates a refined microstructure with good ductility and strength.

Complete Annealing

Here, the steel is heated above the upper (Ac3) critical temperature to create a fully austenitic structure. Afterward, it is cooled very slowly in the furnace.

Subcritical Annealing

This process heats the material just below the lower critical temperature. It is used to relieve stress and reduce the hardness of the metal without forming an austenitic structure.

Spheroidizing Annealing

Spheroidizing is used to change the carbides inside steel into small, rounded shapes. This makes high-carbon steel much easier to machine, and also improves the toughness of the parts.

Recrystallization Annealing

In this process, the metal is heated above its recrystallization point to create a new, grain-free structure, which improves ductility.

Bright and Open Air Annealing

Bright Annealing is done in a controlled atmosphere (usually hydrogen or nitrogen) to prevent surface oxidation. This keeps the material’s surface clean. It is usually used for non-ferrous metals as well.

However, Open Air annealing is usually done in the presence of air. This exposure to oxygen results in surface scaling, which has to be removed.

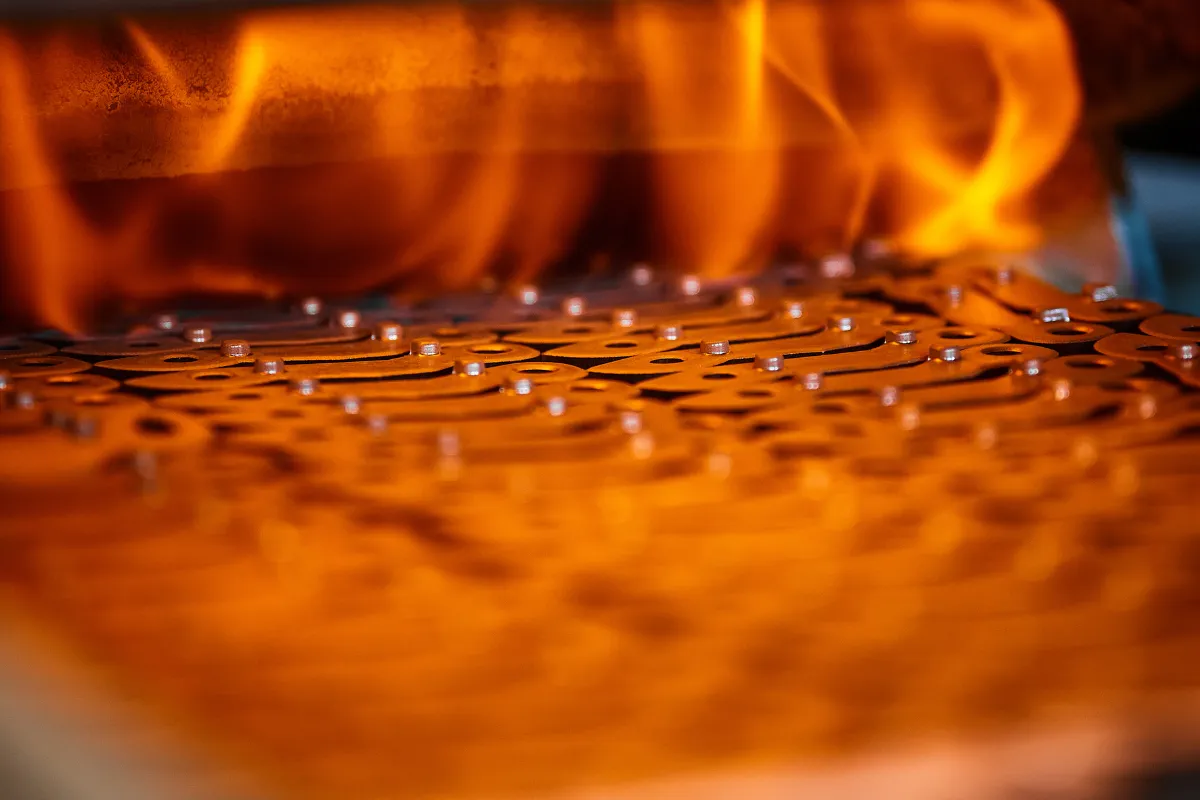

Flame Annealing

This is a localized method where a controlled flame is used to heat the surface of the metal. It usually works well for large pieces that need precise treatment.

Quench Annealing

Here, the metal is heated to a very high temperature, but instead of being cooled slowly, it is cooled down rapidly by dipping it in water or another liquid. It is mostly used for stainless steel to make it highly resistant to rust.

Beta Annealing

This is a specialized process that works for titanium alloys. The metal is heated into its beta phase field, and then cooled in a controlled manner to achieve the desired properties.

Process Steps & Equipment

Annealing usually follows three key steps:

- Chauffage: The material is heated above its recrystallization temperature, and the exact level depends on the alloy being worked with.

- Soaking: The workpiece is then held at that temperature for a set time to allow the structure to adjust fully.

- Controlled Cooling: The cooling process is usually slow, and it influences the metal’s final properties.

The equipment used varies by production scale. Batch furnaces are used for small runs, while continuous furnaces are used to handle large volumes. Also, vacuum or gas-filled chambers are used to protect surfaces from oxidation.

Benefits of Annealing

There are many clear advantages to annealing:

- It lowers the hardness of the metal and increases ductility, which enhances machinability.

- It removes harmful internal stresses in the workpiece.

- It also saves time and reduces wear on cutting tools.

Drawbacks of Annealing

You should also take note of some trade-offs that come with the annealing process:

- The main downside is that it reduces the strength of the material if the heat isn’t controlled properly.

- Full annealing cycles can last many hours, which slows down production time.

- Surface oxidation can occur in open-air furnaces, which need extra cleaning afterward.

Applications industrielles

Automotive & Toolmaking

A lot of car parts are usually annealed before being machined. They include:

- Engrenages

- Vilebrequins

- Housing Brackets

Annealing is also used to improve high-machinability in high-carbon steels for toolmaking. This allows complex shapes to be formed before hardening.

Importance in Nickel Alloys

Nickel alloys that are used in high-temperature or corrosive environments benefit a lot from annealing. The process restores strength and stress resistance, which keeps them reliable in critical parts.

Applications Across Various Metals

Copper is annealed to keep its high electrical conductivity while making it easier to bend or draw. Aluminum parts are also treated to reduce their hardness and remove internal stress before forming. Glass products also undergo annealing to relieve stress. Without it, they could crack during cooling or later use

Choosing the Right Annealing Method

The right method to use depends on the material and what it will be used for. Full annealing is better suited for cast steel parts before they are machined, while stress relief is best for welded parts. The stage of production matters. Early annealing can make forming easier.

It is also best to consult heat-treatment experts to ensure the correct settings for each job. Following alloy-specific guidelines will also help you prevent costly mistakes.

Conclusion

Whether you’re refining copper or shaping steel, annealing ensures the material will perform at its best. If you’re looking for expert annealing services, Nous contacter for your next project.

Découvrez-en davantage avec nos articles de blog.

Messages récents

Découvrez-en plus sur nos produits.

Produits récents

Devis instantané !