Le forgeage de l'aluminium est un élément majeur de l'industrie manufacturière moderne...

Precision Engineering Investment Casting Service

One-stop investment casting service from design, manufacturing, finishing, to shipping. Deliver precision castings for customers worldwide.

• Certifié ISO

• Solution unique

• Competitive Price

Investment Casting Services

Top investment casting foundry in China, delivering casting solutions for complex and precision components.

Vacuum Investment Casting

Casting in an oxygen-free environment brings castings with high precision and quality.

- Vacuum environment prevents defects

- Clean and smooth surface finish

- Haute précision dimensionnelle

- Suitable for complex thin-wall structures

Apprendre encore plus

Super Alloy Investment Casting

Cast with super alloys, built high-strength castings for demanding applications.

- Material range: Inconel, Hastelloy, etc.

- Suitable for high temperature and corrosive environments

- Perfect for turbine and engine components

Apprendre encore plus

Traitement thermique

Precise control of temperature and cooling rate improves casting performance and eliminates defects

- Processes: Annealing, Normalizing, Quenching, and Tempering

- Eliminates casting stress, stabilizes dimensions & shape, and enhances mechanical properties

Apprendre encore plus

Matériaux et finitions de surface

Over 30+ metal materials are available in HDC to satisfy requirements in different applications

Matériaux de moulage

Superalliage

Traitement de surface

sablage/perlage

Cleans surface scale, rust, residue for a uniform matte or satin finish

Mechanical Polishing

Remove burrs and flashes for a uniform, smooth, high-gloss surface

Galvanoplastie

Enhance wear and corrosion resistance by chromium or nickel coatings

Revêtement en poudre

Balancing environmental friendliness with outstanding coating performance

Peinture

Rich color options, enhanced corrosion resistance

Needs Different Material or Finish?

Don’t see your desired options in the list above? Don’t worry! HDC’s capabilities extend beyond standard options. Please consult with us for your special material and finish needs.

Secteur d'activité que nous servons

Diverse investment casting solutions for different industries with our over 15 years of expertise

Contrôle qualité rigoureux

Our quality control goes through the whole casting process, from the material to the final product, ensuring every product meets your expectations.

Certifications :

✓ ISO 9001:2015

✓ ISO 14001:2015

✓ AS9100

Material Composion Anylize

Analyze the chemical composition with a spectrometer for the raw material

Mechanical Performance Testing

Hardness and tensile strength testing to ensure mechanical properties meet standards

Casting Process Control

Monitors key parameters throughout the investment casting process to ensure consistent quality

Fluorescent Penetrant Inspection

Detects defects in castings using a fluorescent dye and ultraviolet light for high-sensitivity flaw identification

Pourquoi choisir HDC

We deliver exceptional castings through custom solutions and precision manufacturing

Solution unique

- End-to-end solutions from design to delivery

- Integrated in-house capabilities (tooling, casting, finishing, QA)

Options de personnalisation riches

- Over 30 materials and finishes available

- Custom alloy for specific applications

- Project-specific process optimization

Service mondial

- Conforme aux normes de qualité internationales

- Multigualiul technical support

- Localized compliance expertise

Des prix compétitifs

- Continuously optimizing the casting process to lower defect rates

- Leverage mature supply chains for cost-efficient sourcing

En savoir plus sur HDC

Go through our facility and equipment list, learn more about HDC's casting capabilities

| Équipement | Caractéristiques | Quantité |

| Machines d'injection de cire | – | 5 |

| Fours de fusion sous vide | Capacité de 50 kg, 100 kg | 2 |

| Fours à induction moyenne fréquence | 250 kg (2 unités), 100 kg (1 unité) | 3 |

| Fours de cuisson à coquille | – | 2 |

| Fours de traitement thermique | – | 2 |

| Grenailleuses | – | 5 |

| Machines de sablage | – | 2 |

| Spectromètre | SPECTRO Allemagne, 5e génération, lecture directe | 1 |

| Machine d'essai de traction | – | 1 |

| Système d'alimentation électrique | Transformateurs de type boîte 630 kVA | 2 |

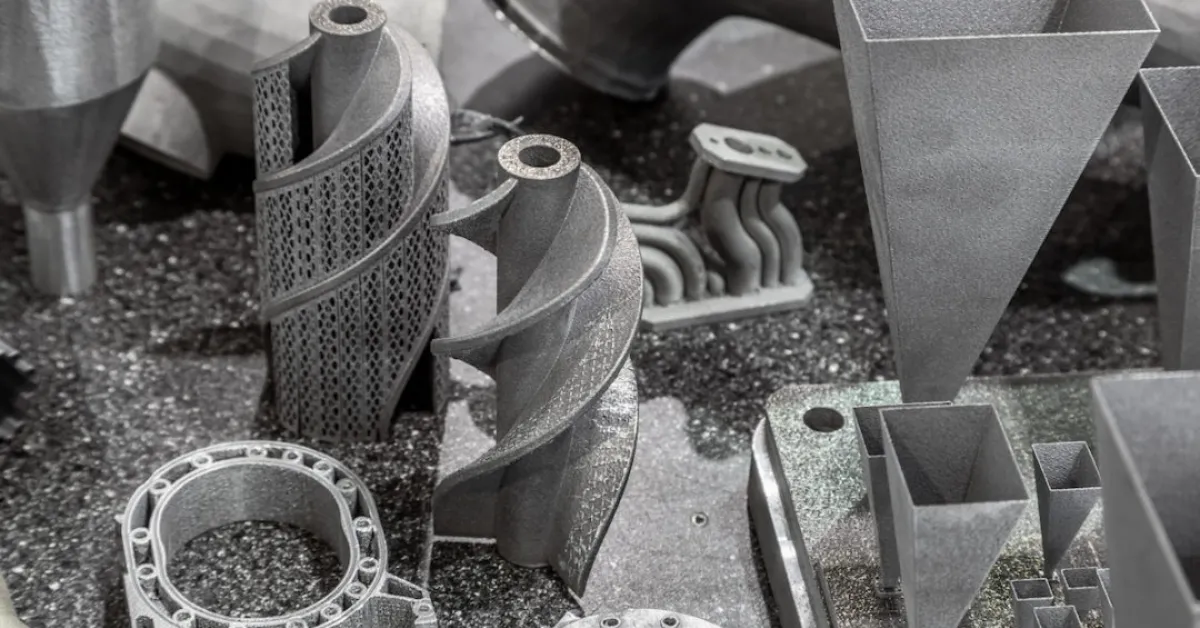

What is Investment Casting

Investment Casting is a precision casting process, also known as the “lost wax casting”. It is known for its ability to produce metal castings with extremely complex shapes, high dimensional accuracy, and good surface finish, especially for high melting point alloys or complex parts that are difficult to machine by other methods.

The Process of Investment Casting

The main process of investment casting can be divided into the following six steps:

- Wax Pattern Production: Create a metal mold based on the final part shape, then inject low-melting-point wax under pressure into the mold to obtain a precise wax pattern.

- Shell Building (Investment): The wax model is repeatedly immersed in the ceramic slurry, and after each dipping, a layer of fine sand made of refractory material is sprinkled, and this process is repeated several times until a ceramic shell with sufficient thickness (usually 5-15mm) and sufficient strength is formed on the surface of the wax mold

- Dewaxing (Wax Removal / Lost-Wax Process): After the ceramic shell is dried and hardened, it is placed in a high-temperature steam oven to allow the wax mold inside to melt and flow out, which is also the origin of the name “lost wax casting”.

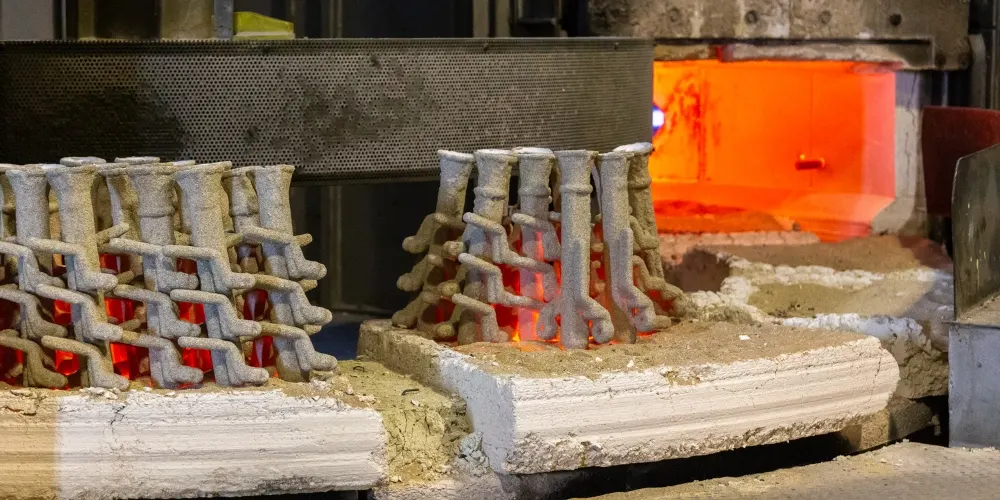

- Shell Sintering: Place the dewaxed ceramic shell into a high-temperature furnace for firing to enhance its strength.

- Fonderie: Pour the molten metal into the cavity of the shell mold.

- Shell Removal & Post-Processing: After the metal is completely solidified, the outer layer of ceramic shell is removed by mechanical vibration, sandblasting, etc. The gating hole is then cut off, and subsequent processes such as heat treatment, sandblasting, polishing, machining, and surface treatment are carried out as required.

Investment Casting Flow

Below is our comprehensive investment casting process flow

FAQ

Answers for commonly asked questions about our investment casting service

Yes, with our experienced engineers and in-house CNC machining capability, we can design and manufacture molds, providing rapid support for design changes.

Yes, we provide scalable production services, from prototypes to mass production runs of over 2,000 units per month. HDC can meet all your needs

Yes, we provide prototypes for quality verification and function adaptation tests before mass production.

We can cast parts with a weight from 0.1kg to 100kg and size within 500mm x 500mm x 500mm.

Yes, we offer after-sales service and are responsible for quality issues caused by the manufacturing process and material.

We offer air, sea and rail transportation, as well as express delivery services. If you have different requirements, please contact us for details.

Obtenez un devis gratuit

Ready to discuss your requirements? Our engineering team is standing by to provide expert consultation and competitive pricing.

Demander un devis gratuit

Ressources connexes

Fonderie de métaux à la cire perdue ou forgeage de métaux : 8 éléments à prendre en compte

Le choix entre le moulage à la cire perdue et le forgeage dépend de vos besoins spécifiques...

Comparaison entre l'impression 3D, le forgeage et le moulage par cire perdue

Découvrez les différences entre l'impression 3D métal, le forgeage et l'investissement...

Top 20 des fabricants de pièces forgées en aluminium en Chine 2024

La liste suivante répertorie les dix principales entreprises de forgeage d'alliages d'aluminium...

Forgeage en matrice fermée vs. Forgeage en matrice ouverte

Le forgeage en matrice fermée et le forgeage en matrice ouverte sont des techniques de forgeage des métaux...