- Maison

- Ressources

- Blog

- Options de couleur de titane

Connaissez-vous la couleur naturelle du titane ? Avez-vous conscience de sa teinte naturelle après son extraction ? Dans ce blog, nous nous intéresserons à l'identification de la couleur naturelle du métal du futur.

De plus, comme le titane est connu pour être traité et raffiné, nous examinerons également les couleurs disponibles du titane après traitement et raffinage.

Sans plus tarder, commençons à en savoir plus sur le titane !

Le titane en quelques mots

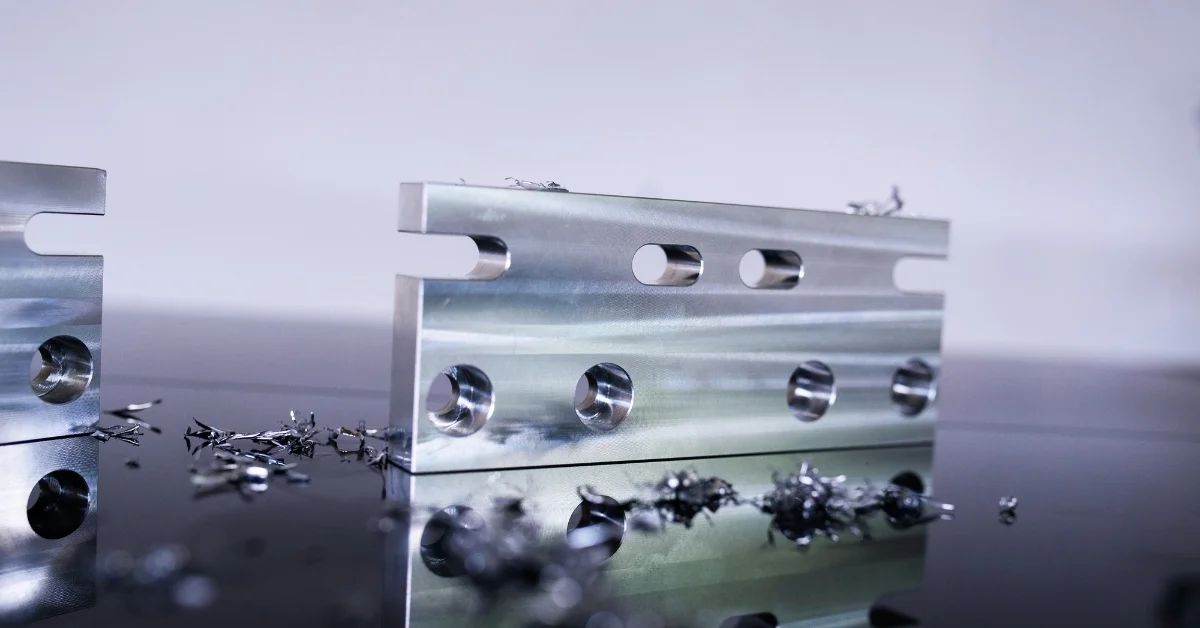

Le titane fait partie de la famille des métaux et est connu pour être léger, solide et résistant à la corrosion. Il est le propriétaire légitime du symbole chimique (Ti) et du numéro atomique 22.

Ce métal gris argenté est utilisé dans de nombreux objets du quotidien et composants de machines. Dans l'ensemble, le titane est un métal prospère que de nombreuses entreprises et sociétés doivent faire valoir

Qui a découvert le titane ?

En 1791, William Gregor, un ecclésiastique et minéralogiste britannique, a découvert le titane alors qu’il étudiait le sable dans la vallée de Manaccan. Il a identifié un oxyde de fer et un métal inconnu, qu’il a nommé « ménachanite ».

Malheureusement, sa découverte passa inaperçue à l'époque. Le matériau analysé par Gregor, aujourd'hui appelé ilménite, reste le minerai le plus important pour l'extraction du titane. En 1795, le chimiste allemand Martin Heinrich Klaproth redécouvrit le titane lors de ses recherches sur le rutile.

Il lui a donné le nom des Titans de la mythologie grecque, non pas pour sa force, mais parce que son nom semblait neutre, suivant les principes d'Antoine Lavoisier.

À quoi ressemble la couleur du titane ?

La plupart des gens ont des idées fausses sur la couleur du titane. Ils le voient comme étant noir, gris, argent, parfois même vert. Mais quelle est la vraie couleur du titane ? Quelle est sa couleur naturelle ?

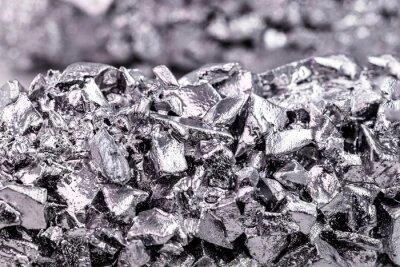

La couleur naturelle du titane lorsqu'il est extrait de la terre est argentée, blanc grisâtre avec une teinte brillante. Sa surface est souvent naturellement brillante et polie.

La beauté du titane est qu’il peut prendre presque toutes les couleurs nécessaires grâce au processus d’anodisation.

Le titane est-il une couleur grise ?

Oui et non, laissez-moi vous expliquer. Le titane est une teinte laiteuse, argentée, gris-blanc dans sa forme la plus naturelle. Cela signifie qu'il n'est pas d'une seule couleur en raison de son aspect brillant et rugueux.

Oui, c'est du gris parce que sa teinte se rapproche davantage de celle de l'argent, du gris et du blanc. Non, parce que ce n'est pas vraiment du gris comme nous le connaissons, c'est plutôt une couleur grisâtre, blanc laiteux.

C'est l'esthétique naturelle du titane lorsqu'il est extrait des minerais d'ilménite et de rutile. C'est la couleur typique que vous verrez après l'extraction des minerais.

REMARQUE: Pour la plupart des gens qui savent que le titane est gris, cela pourrait être dû au titane anodisé de type 2, où la résistance à l'usure est augmentée et améliorée, et le pigment ou la surface devient gris moyen foncé.

De quelles autres couleurs peut être le titane ?

L'une des caractéristiques les plus appréciées du titane est son esthétique, son attrait. Bien que sa couleur naturelle soit un blanc laiteux et argenté, vous pouvez également l'obtenir dans d'autres couleurs. Comment ? Par anodisation.

L'anodisation est la méthode la plus courante pour améliorer les propriétés globales du titane. En outre, la couleur de sa surface change également.

Anodisation au titane de types 1, 2 et 3

Pour mieux comprendre les couleurs, il est impératif que vous connaissiez les différents types de couleurs. titane anodisé.

REMARQUE: Le type 1 n'est pas souvent utilisé et est considéré comme le moins courant. Ils sont généralement utilisés dans les applications à haute température.

Titane anodisé de type 2

L'anodisation de type 2 est principalement connue pour améliorer la résistance à l'usure et réduire la friction entre les surfaces en titane. Ce procédé crée une couche d'oxyde protectrice sur le titane, ce qui réduit considérablement la production de poussière de titane indésirable lorsque les pièces frottent les unes contre les autres.

La surface résultant de l'anodisation de type 2 est d'une couleur grise distincte, offrant une nette différenciation par rapport au titane non traité ou à d'autres matériaux comme l'acier inoxydable. Cette finition est obtenue grâce à des étapes supplémentaires telles que le grenaillage pour éliminer tout film blanc résiduel après le processus d'anodisation.

Titane anodisé de type 3

D'autre part, ce procédé est largement utilisé dans le domaine médical, car il permet une identification visuelle rapide des pièces lors des interventions. Par exemple, les chirurgiens peuvent facilement distinguer les vis osseuses ou les plaques de fixation en fonction de leurs couleurs, ce qui simplifie les opérations.

Le spectre de couleurs disponible grâce à l'anodisation de type 3 va de l'or, du violet et du bleu au bleu sarcelle, au vert et au magenta, selon l'épaisseur de la couche d'oxyde.

REMARQUE: Il convient toutefois de noter que les tons rouges ne sont pas réalisables en raison des limitations physiques du phénomène d'interférence qui crée les couleurs.

Le titane rouille-t-il ou devient-il vert ?

La réponse rapide et facile est non, ce n'est pas le cas. Le titane ne rouille pas car il ne contient pas de fer, qui est nécessaire à la formation de la rouille.

Au contraire, lorsqu'il est exposé à l'air, le titane développe une fine couche protectrice de dioxyde de titane. Cette couche empêche la corrosion et améliore sa résistance à l'humidité et aux dommages environnementaux.

Quant au verdissement, le titane ne présente pas ce comportement dans des conditions normales. La décoloration verte est courante avec des métaux comme le cuivre, qui forment une patine au fil du temps. La couche d'oxyde stable du titane l'empêche de réagir de la même manière.

Cependant, vous pouvez le transformer manuellement en vert si vous le souhaitez, à condition que vous l'anodisez pour améliorer l'esthétique.

Comment le titane est-il anodisé ?

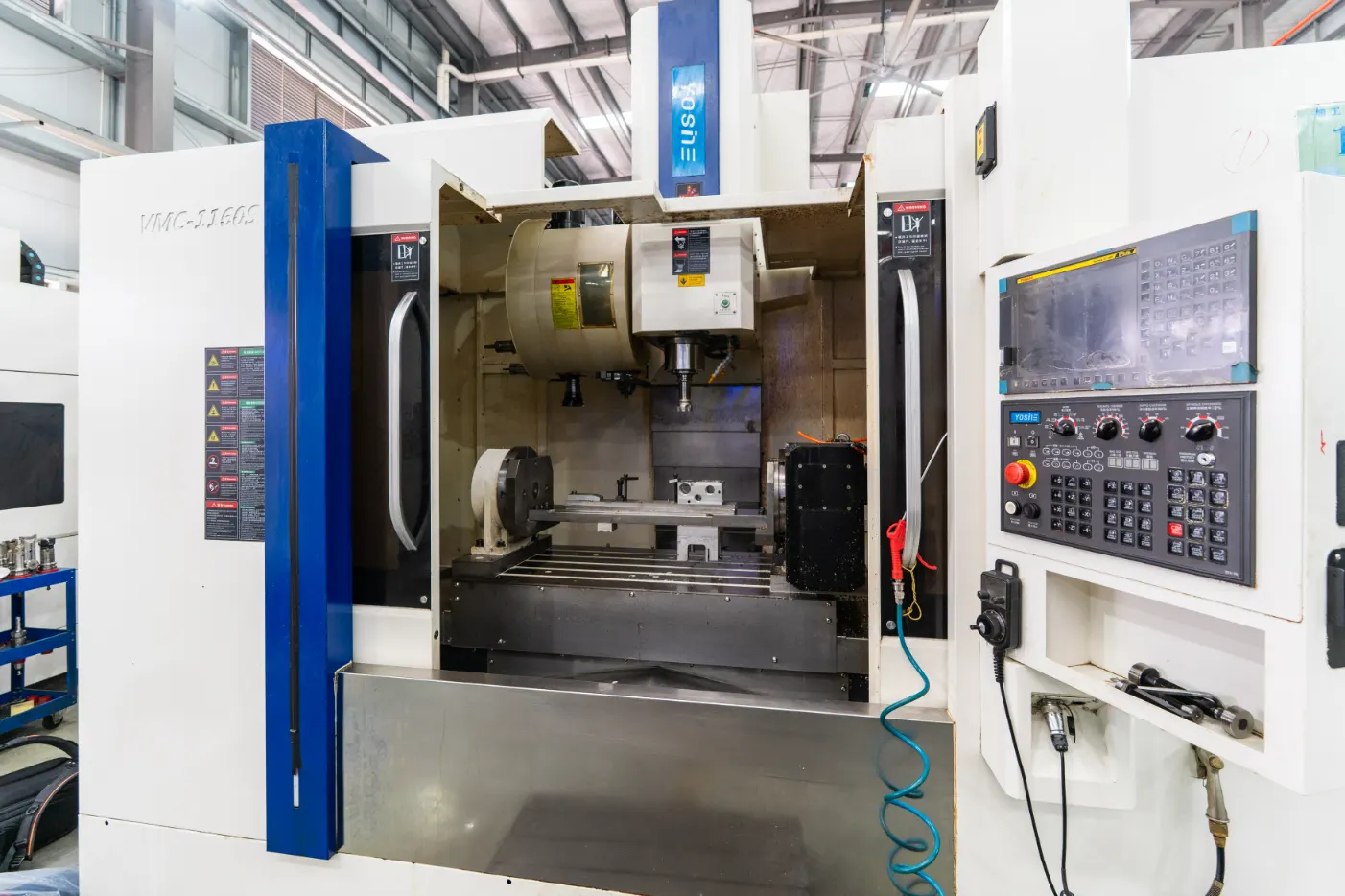

Le processus d'anodisation du titane diffère d'un fabricant à l'autre. Mais pour ce processus, nous avons décrit la procédure courante et la plus suivie par les entreprises pour l'anodisation du titane.

Regardez cette vidéo ! L'utilisateur présente le processus d'anodisation du titane, en changeant ses couleurs en fonction de la tension.

L'anodisation du titane est un procédé électrochimique qui améliore sa surface en créant une couche d'oxyde contrôlée, qui reflète des couleurs vives. Voici donc une description simplifiée de son fonctionnement :

Étape #1 : Préparation

La première étape est souvent la plus critique. Le titane est nettoyé à l'aide d'une solution alcaline pour éliminer la graisse, la saleté ou les contaminants organiques.

Cela permet de garantir que la surface est uniforme et plate pour le processus d’anodisation.

Étape #2 : Bain d'électrolyte

Ensuite, c'est à l'étape suivante que la magie opère. Le titane est immergé dans une solution électrolytique, souvent du phosphate trisodique (TSP).

Cette solution agit comme milieu pour la réaction électrochimique, provoquant les changements de surface ainsi que les propriétés du titane.

Étape #3 : Application de la tension

Après le bain, on laisse reposer le composant quelques minutes pour le laisser suinter. On applique ensuite un courant continu, le titane servant d'anode (électrode positive).

La tension détermine l'épaisseur de la couche d'oxyde et la couleur résultante.

Étape #4 : Formation de la couche d'oxygène

L'électricité provoque la séparation des molécules d'eau dans la solution, libérant ainsi de l'oxygène. Cet oxygène se lie à la surface du titane, formant une couche d'oxyde.

Étape #5 : Création de couleurs

Ensuite, l’épaisseur de la couche réfracte la lumière, produisant un effet d’interférence qui crée différentes couleurs sans colorants.

Le réglage de la tension peut produire des nuances allant du bronze au vert, mais pas du rouge pur en raison de la physique optique. Ainsi, pour ajuster la couleur, vous devez ajuster la tension pour obtenir la couleur ou la teinte spécifique que vous recherchez.

Étape #6 : Rinçage final et inspection

Une fois la couleur souhaitée obtenue, la pièce est rincée et inspectée pour en vérifier la consistance. Dans la plupart des cas, les fabricants soumettent leurs produits finis à une évaluation et à une inspection de qualité strictes pour détecter les déformations et les défauts.

Et c'est le processus habituel étape par étape de la façon dont le titane est anodisé ; c'est ainsi qu'ils obtiennent les différentes couleurs que vous les connaissez.

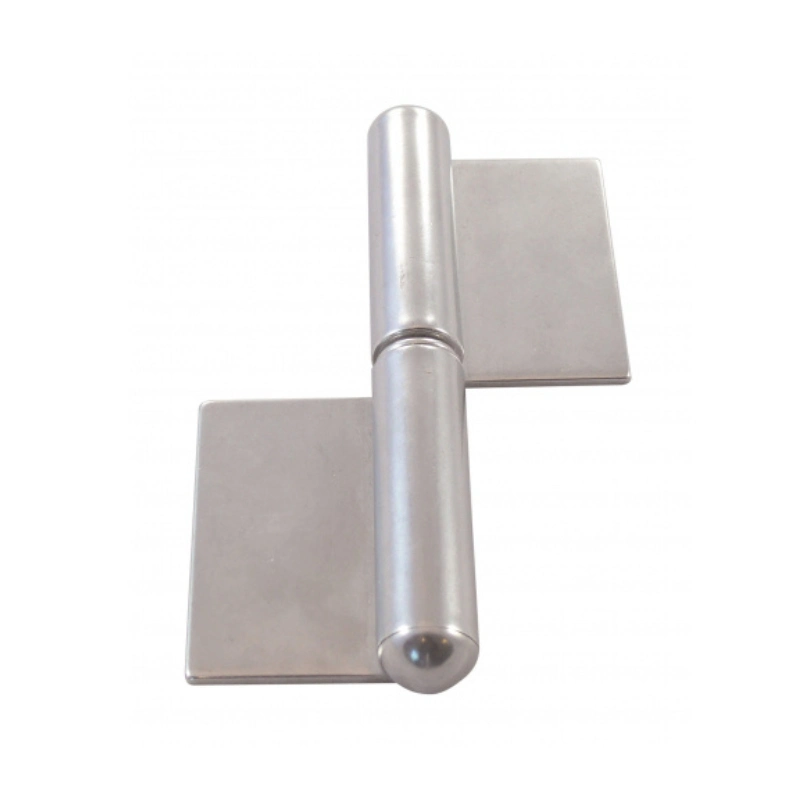

Où trouver du titane pour les composants et les pièces

Il existe en fait d’innombrables domaines dans lesquels vous pouvez vous procurer du titane, et tout dépend du type de titane que vous souhaitez. Certains fournisseurs souhaitent recevoir leurs commandes de titane brut, à partir de la source ou du minerai.

Pour ces types de minerais, il faut s'adresser directement à une société minière. Celle-ci ouvre souvent des commandes de titane en fonction du poids et du volume.

Cependant, si vous avez besoin de titane amélioré et prétraité, vous pouvez vous en procurer auprès d'entreprises qui le proposent, comme nous ici chez HDC. HDC est l'un des fournisseurs les plus fiables et les plus fiables de Chine pour différents alliages, aciers inoxydables et même pièces en plastique.

En plus de nous, vous pouvez également vous adresser à des fabricants américains, européens et autres fabricants asiatiques ! Mais si vous souhaitez une qualité de classe mondiale, n'hésitez pas à nous contacter ainsi qu'à notre équipe d'experts.

Découvrez-en davantage avec nos articles de blog.

Messages récents

Découvrez-en plus sur nos produits.

Produits connexes

Devis instantané !