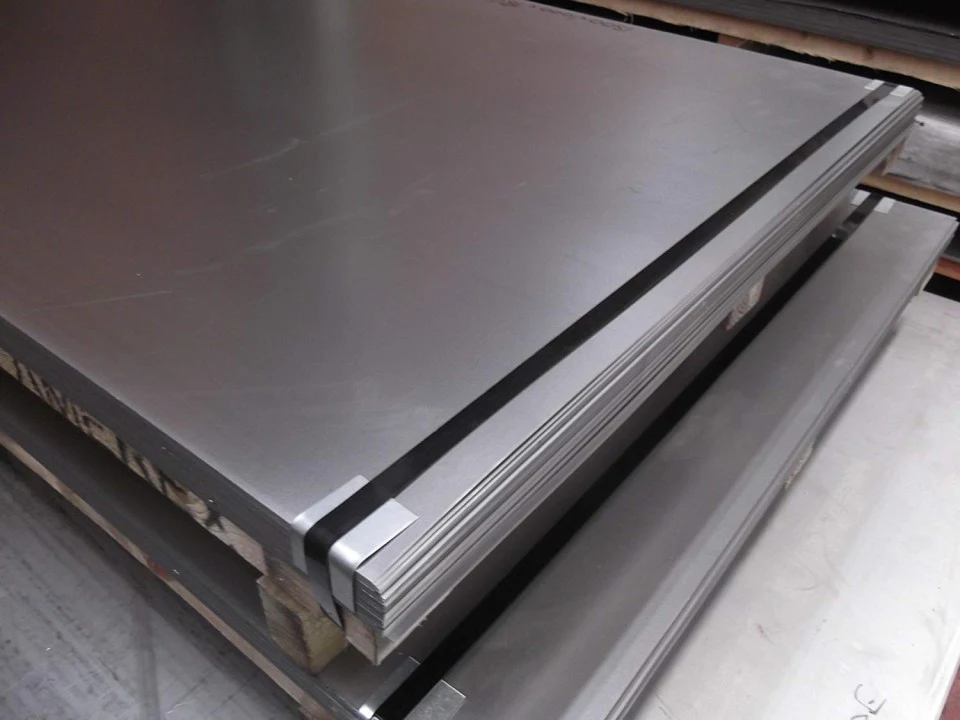

One of the most commonly used grade of stainless steel is the 440 stainless steel. It is a highly versatile material known for its strength, corrosion resistance, and exceptional hardness. It belongs to the martensitic family of stainless steels and is widely used in industries requiring high-performance materials. This article explores the properties, composition, and benefits of 440 stainless steel, along with its applications and comparison to other grades.

What is 440 Stainless Steel?

440 acciaio inossidabile is a high-carbon stainless steel that offers superior hardness and wear resistance. It is classified into three main sub-grades: 440A, 440B, and 440C, each with slightly varying carbon content. These variations allow manufacturers to choose the appropriate grade for specific applications, balancing hardness, corrosion resistance, and machinability.

What are the Main Properties of 440 Stainless Steel?

1. High Hardness

440 stainless steel is renowned for its ability to achieve exceptional hardness through heat treatment. If you are wondering how high the hardness can reach, then the 440C, which is the hardest variant, can reach a Rockwell hardness of up to 60 HRC, making it suitable for cutting tools and wear-resistant applications.

2. Corrosion Resistance

While primarily designed for hardness and strength, 440 stainless steel also provides good corrosion resistance due to its chromium content. This makes it suitable for applications exposed to moisture and mild chemicals.

3. Strength and Wear Resistance

The high carbon content in 440 stainless steel gives it outstanding strength and wear resistance, ideal for demanding environments where durability is a priority.

4. Heat Treatability

One of the distinguishing features of 440 stainless steel is its ability to undergo heat treatment. This process allows the material to achieve optimal mechanical properties for specific applications.

Composition of 440 Stainless Steel

| Elemento | Percentage |

| Cromo | 16–18% |

| Carbonio | 0.60–1.20% |

| Manganese | ≤ 1% |

| Silicio | ≤ 1% |

| Molibdeno | ≤ 0.75% (in some variants) |

| Sulfur & Phosphorus | ≤ 0.04% |

What are the main Variants of 440 Stainless Steel?

- 440A

- Lower carbon content: Provides better corrosion resistance at the cost of reduced hardness.

- Ideal for applications requiring toughness over extreme hardness.

- 440B

- Medium carbon content: Balances hardness and corrosion resistance.

- Used in tools, bearings, and industrial components.

- 440C

- Highest carbon content: Offers maximum hardness and wear resistance.

- Commonly used for high-precision cutting tools, knives, and surgical instruments.

Applications of 440 Stainless Steel

Due to its unique properties, 440 stainless steel is used across various industries:

1. Cutlery and Kitchen Tools

High-quality knives, scissors, and blades are often made from 440C stainless steel due to its exceptional edge retention and wear resistance.

2. Surgical Instruments

The high hardness and corrosion resistance of 440 stainless steel make it a preferred choice for scalpels, dental instruments, and other medical tools.

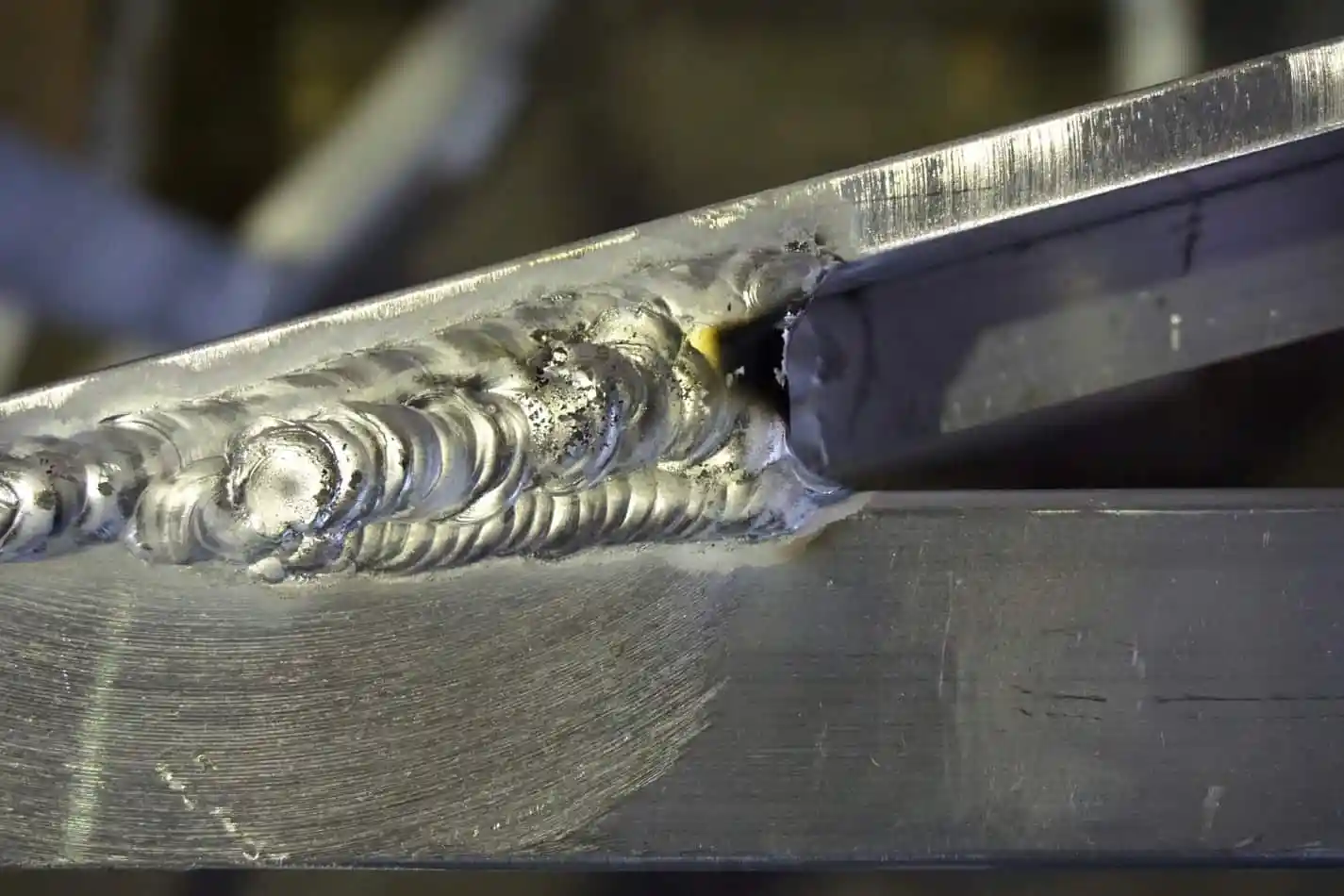

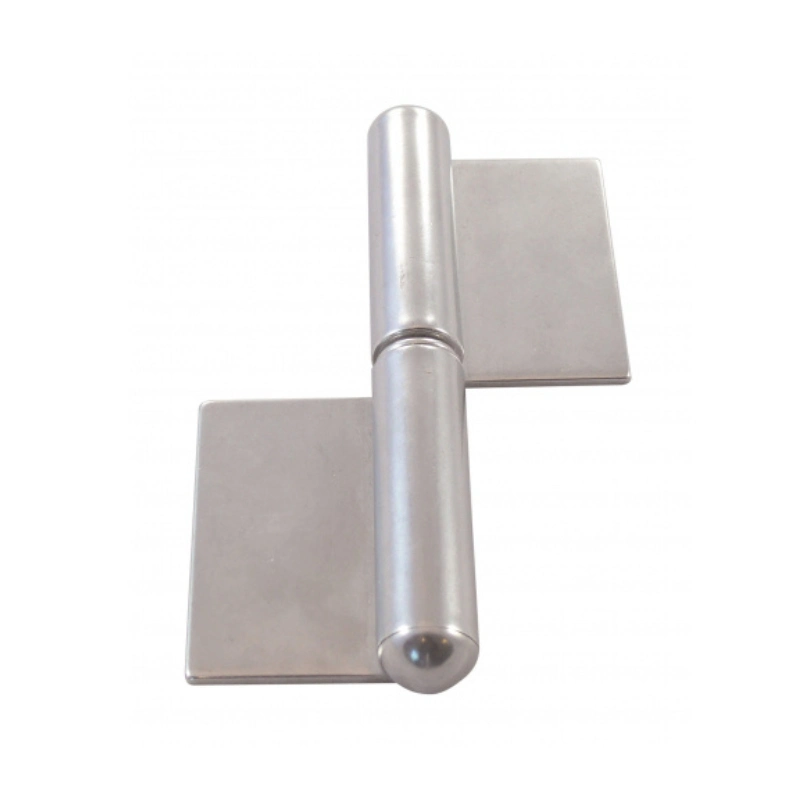

3. Industrial Components

440 stainless steel is used for bearings, valves, and gears where wear resistance and strength are critical.

4. Settore automobilistico e Aerospaziale

In these industries, 440 stainless steel is utilized for precision parts exposed to stress and friction, such as shafts and fasteners.

5. Wear-Resistant Tools

Applications like molds, dies, and measuring instruments benefit from the material’s hardness and durability.

Limitations of 440 Stainless Steel

- Brittleness: At higher hardness levels, 440 stainless steel can become brittle, limiting its use in applications requiring flexibility.

- Difficult Machinability: Its hardness and high carbon content make it challenging to machine, increasing production costs.

- Lower Corrosion Resistance than Austenitic Grades: Compared to grades like 304 o 316, 440 stainless steel offers less corrosion resistance.

Comparing 440 Stainless Steel vs. Other Stainless Steel Grades

| Proprietà | Acciaio inossidabile 440 | Acciaio inossidabile 304 | Acciaio inossidabile 316 |

| Durezza | Very High (up to 60 HRC) | Basso | Moderare |

| Resistenza alla corrosione | Moderare | Alto | Superior |

| lavorabilità | Difficult | Easy | Moderare |

| Applicazioni | Cutting tools, medical instruments | General-purpose cookware, industrial applications | Marine, chemical environments |

Heat Treatment Process for 440 Stainless Steel

The performance of 440 stainless steel can be enhanced through heat treatment, which involves:

- Indurimento: Heating the material to a high temperature (around 1010–1065°C), followed by rapid cooling to achieve maximum hardness.

- Temperamento: Heating to a lower temperature (150–370°C) to balance hardness and toughness, reducing brittleness.

Conclusione

440 stainless steel is a remarkable material that excels in hardness, wear resistance, and moderate corrosion resistance. Its versatility, combined with the availability of sub-grades like 440A, 440B, and 440C, makes it suitable for a wide range of industrial and commercial applications.

While it has limitations such as brittleness at high hardness and reduced corrosion resistance compared to austenitic grades, its advantages in strength and durability make it an indispensable choice in industries requiring high-performance materials.

Scopri di più con i post del nostro blog.

messaggi recenti

Scopri di più sui nostri prodotti.

prodotti correlati

Preventivo immediato!