In this blog, you will learn about the different stainless steel grades. Yes, you read that right, we will take it up a notch and give you relevant and valuable information about the different grades of stainless steel.

We’ll discuss how you can identify different stainless steel types. So, by the end of this blog, you’ll not be wondering about a specific stainless steel grade any longer!

Identifying Stainless Steel

Source: ASL Engineering

Because of its vast use and applications, you’ll find many different kinds and types of stainless steel. So, we can identify them today as families and grades.

The families and grades are two different categories for stainless steel. Long story short, each stainless steel grade is part of a stainless steel family.

To help you understand them more, let’s take a look at what these all mean.

Families of Stainless Steel

Source: Thermo Fisher

Stainless steel “families” refer to particular properties of said grades. They help give an idea as to the ratio of different metals.

There are four different families of stainless steel, they are:

Acciaio inossidabile austenitico

Austenitic stainless steels are among the most popular and widely used non-magnetic alloys worldwide.

They typically feature chromium and nickel, with some grades also containing manganese or molybdenum for added properties.

NOTA: Some of the most notable grades in this family include 303, 310, 316, and 321.

Acciaio inossidabile duplex

Duplex stainless steels blend features of both austenitic and ferritic families, and they include many of the most recent alloys innovated.

Depending on the alloy, these steels are designed to address specific needs like increased strength, reduced weight, or improved corrosion resistance.

NOTA: The most notable grades are LDX 2101, 318L, 4501, and 2507.

Acciaio inossidabile ferritico

This family contains the grades that have the lowest nickel content. They’re also affordable and extremely easy to source. So, in case you were asking, does stainless steel have nickel? – grades in the ferritic family do.

Ferritic steels are magnetic and are often imbued with titanium, niobium, chromium, and molybdenum.

NOTA: Common ferritic grades are 441, 409, 430, and 439.

Martensitic and Precipitation Hardening Stainless Steel

Lastly, martensitic and precipitation hardening. They’re the rarest and the least common used stainless steel. They are, however, heavily valued in accurate and precise applications.

Their carbon content allows for tempering and hardening, making them the top choice for knives, scissors, and medical tools.

NOTA: These martensitic grades often include 440, 416, 410, and 420.

Gradi di acciaio inossidabile

Now that you know the different families (and some of the more common grades), it’s time for you to know and understand the different grades.

Before we dive deep into that, how were these stainless steel creations graded? How were they categorized as they are?

Il Society of Automotive Engineers (SAE) grading system is what many consider as the oldest. They feature a 3-digit number (e.g., 304, 410, 416, etc.). But wait, there’s more!

You might also see other ways of grading, like in North America, most are graded using six characters and they’re done by the American Society for Testing and Materials (ASTM).

Grado | Family | Descrizione | Applicazioni | Suitability |

200 Series | austenitico | Chromium-nickel-manganese alloy | Indoor appliances, interior automotive components | Affordable option for areas where minimal corrosion resistance is needed. |

300 Series | austenitico | Chromium-nickel alloy | Food equipment, medical devices, construction, sinks | High corrosion resistance due to chromium and nickel, ideal for harsh cleaning environments. |

400 Series | Ferritic & Martensitic | Chromium alloy | Car exhausts, higher-grade cutlery, replica swords | Cost-effective choice for general use where appearance isn’t a priority. |

500 Series | martensitico | Heat-resistant chromium alloy | Furnaces, heat exchangers, boiler parts, turbine blades | Excellent heat resistance for high-temperature industrial applications. |

600 Series | martensitico | Alloy formed by precipitation hardening | Aerospace, oil and gas, medical implants, chemical processing | Superior durability and heat resistance for critical, high-stress environments. |

Type 2205 | Duplex (Austenitic + Ferritic) | Chromium and nickel alloy mix | Oil pipelines, marine uses, paper industry equipment | High-cost, high-performance material with exceptional strength, corrosion resistance, and weldability. |

Type 2304 | Duplex (Lean Grade) | Chromium-nickel alloy with minimal molybdenum | Food processing, treated water piping, construction | Economical duplex choice offering good strength and corrosion resistance, but not for extreme conditions. |

Understanding Stainless Steel Grades More

Source: Mahendra Prajapati

We made that table for you to gain quick information about each grade. But, we won’t be leaving you with that! Here are more information about each grade series!

200 Series

The stainless steels in the 200 series are austenitic alloys that contain manganese, nickel, and chromium.

They are often used in indoor settings where high corrosion resistance is not necessary, such as in appliances and automotive parts.

Price-wise, 200 series steels are less expensive because they contain less nickel, but they might not function well in extremely corrosive conditions.

300 Series

The 300 series stainless steels are austenitic alloys primarily composed of chromium and nickel.

They are widely used in food processing equipment, chemical processing equipment, medical devices, construction materials, and household appliances, including sinks.

Their high chromium and nickel content provides excellent corrosion resistance, making them suitable for harsh cleaning chemicals. They also offer excellent formability and strength.

400 Series

The 400 series stainless steels include ferritic and martensitic alloys primarily composed of chromium.

They are commonly used in car exhausts, some higher-grade cutlery steel, and replica swords and knives. They are among the most cost-effective stainless steels available.

500 Series

The 500 series stainless steels are martensitic alloys that are heat-resistant due to their high chromium content.

They’re used in high-temperature environments such as furnaces and heat exchangers, as well as in industrial applications like boiler parts and turbine blades.

What makes them special is their high heat resistance, allowing them to be suitable for automotive exhaust components and heat shields.

600 Series

And lastly, the 600 series. They’re martensitic alloys formed by precipitation hardening, a special heat treatment process.

Used in aerospace, chemical processing equipment, oil and gas, nuclear reactors, and medical devices like implants. Their high heat resistance makes them suitable for high-temperature applications.

FAQs About Stainless Steel

Here are some of the most commonly asked questions about stainless steel and their grades.

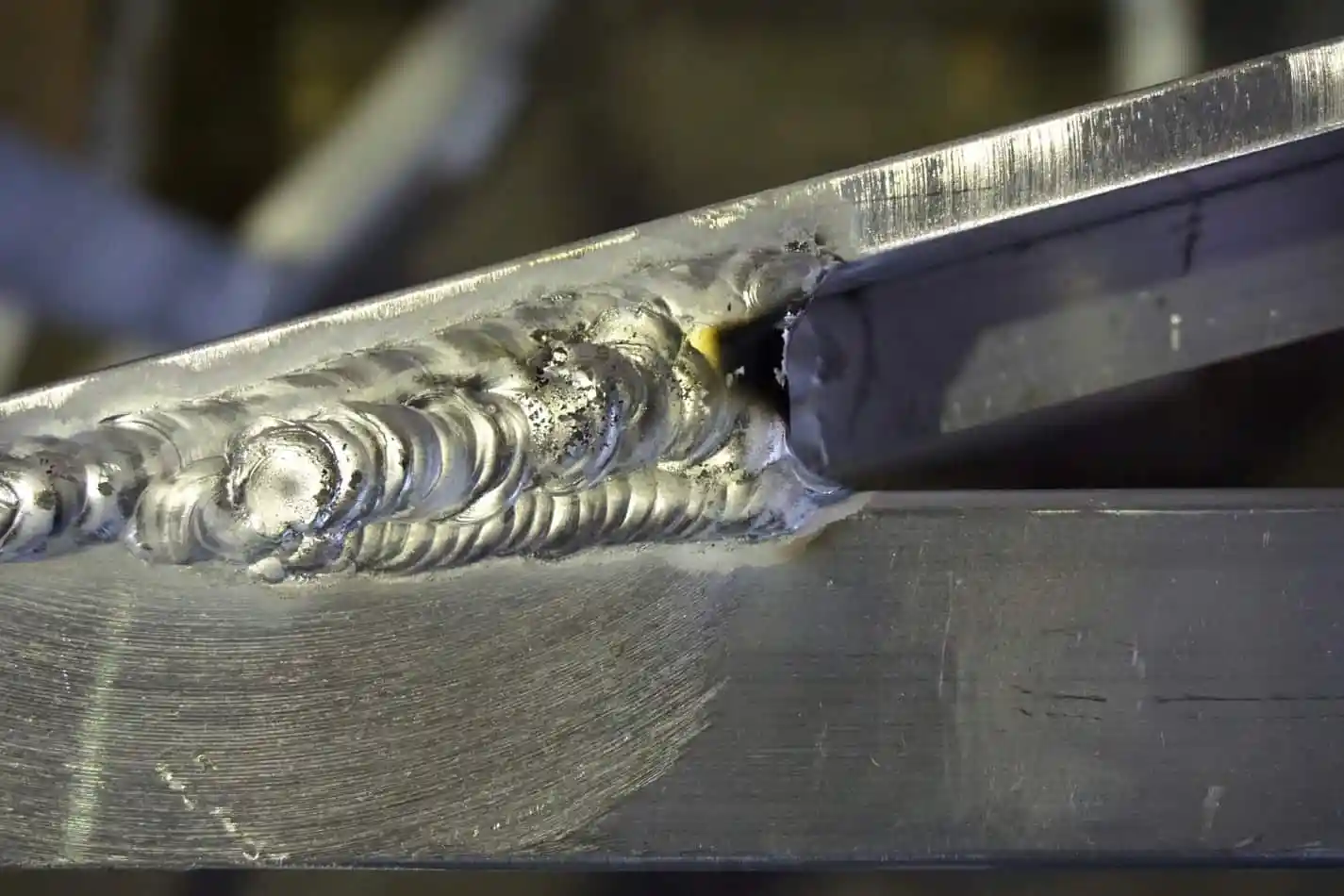

Can You Weld Stainless Steel?

Yes, you can weld stainless steel. However, it’s not a common feat. In addition, it’s also more challenging to weld stainless steel compared to carbon steel.

But can you MIG weld stainless steel? Of course! It is, in fact, one of the preferred ways of welding.

Stainless Steel Grade 304 vs. 316

Being the two-most common stainless steel grades, they’re also the most commonly compared. Their difference lies in their composition: 316 has more molybdenum, but it’s more challenging to get.

304 stainless steel is standard with 8 percent nickel and 18 percent chromium, while 316 has 2 percent molybdenum, 10 percent nickel, and 16 percent chromium.

How to Clean Rust Off Stainless Steel?

Being one of the top materials used for cookware, it’s also commonly asked how to get rust off of it. The best most natural way of removing rust off of stainless steel is by using baking soda.

Sprinkle baking soda on the rusty area, make a paste using water, let it sit for up to an hour, and then rub away with a sponge.

Why Trust HDC for Your CNC Stainless Steel Products

Whatever stainless steel grades you’re looking for, and whatever form you need of them in, HDC is the right spot.

We are the country’s best one-stop solution for metal parts since 2009. Our business specializes in the production and manufacturing of custom CNC and metal products.

Employed with the best engineers and metal fabrication experts, we’re sure to provide whatever stainless steel type you need! So, if you ever need carbon steels, plastica, leghe di nichel, O stainless steels, you can count on us!

Contattaci for more information and to get a free estimate!

Scopri di più con i post del nostro blog.

messaggi recenti

Scopri di più sui nostri prodotti.

prodotti correlati

Preventivo immediato!