Custom Forged Golf Club Heads Manufacturing

Precision forging and CNC machining for OEM golf brands, startups, and product developers.

Leveraging our core expertise in metal forging and CNC finishing, we manufacture custom forged golf club heads and blanks based on your designs or samples.

We focus on reliable manufacturing execution, helping to turn designs into consistent, tour-level products.

What We Manufacture

We support OEM and custom manufacturing of forged golf club components.

Forged Iron Heads

Precision-forged iron heads with controlled material density and CNC-machined geometry, suitable for consistent batch production and brand-level quality requirements.

Forged Wedge Heads

Forged wedge heads manufactured from custom tooling and refined through CNC machining to achieve accurate loft, lie, and groove geometry.

Forged Putter Heads

Forged or semi-forged putter heads and blanks, allowing flexible CNC shaping for complex 3D designs and weight distribution control.

Forged Club Head Blanks

Semi-finished forged blanks supplied for customers who prefer in-house or third-party CNC machining and finishing.

Perché scegliere HDC

Our manufacturing approach addresses the most common challenges faced by golf brands and developers.

Consistency & Batch Stability

Stable forging processes combined with CNC correction ensure uniform weight, geometry, and repeatability from prototype to mass production.

Design-Controlled Customization

We manufacture strictly according to customer designs, supporting private tooling, proprietary geometries, and brand-specific specifications.

Integrated Forging + CNC Capability

All critical processes—from forging to CNC machining and inspection—are managed in-house, reducing coordination risks and lead time uncertainty.

Supporto tecnico

Our engineers support DFM review, sampling, and process optimization, ensuring manufacturability without altering your original design intent.

HDC Core Capabilities

Below are our key manufacturing capabilities that are especially critical for forged golf club components.

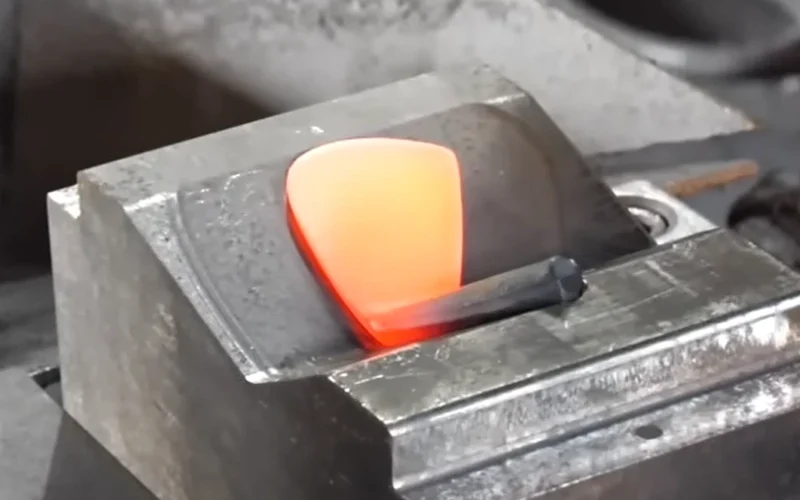

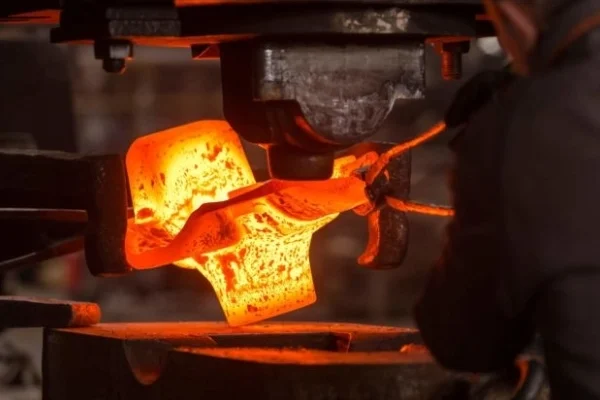

Forgiatura di precisione

Controlled forging ensures consistent material structure and density, forming a stable foundation for subsequent CNC machining.

Heat Treatment & Trimming

Proper heat treatment improves mechanical stability, while trimming prepares uniform forgings for accurate machining.

Lavorazione CNC a 5 assi

Multi-axis CNC machining enables precise control of loft, lie, and complex 3D contours required by modern club head designs.

For a full overview, please visit our Forgiatura e Lavorazione CNC Capability pages.

Available Materials for Forged Golf Clubs

We work with commonly specified golf club materials, selected to meet different design and performance requirements.

Known for its soft feel and excellent machinability, 1020 carbon steel is widely used in forged irons and wedges. Our controlled forging process ensures stable material flow and clean surface quality.

A popular choice for premium forged clubs, offering enhanced feedback and durability. We maintain tight weight tolerance through precision forging and CNC finishing.

Finishes & Surface Treatments

We offer a range of surface finishing options as part of our one-stop manufacturing service, ensuring consistency and durability across batches.

- Satin / Brushed Finish

- Mirror Polish

- Cromatura

- Black PVD / QPQ

- Finitura grezza

Finishing processes are selected based on durability requirements, surface consistency, and compatibility with mass production.

Specifiche tecniche

Below are typical manufacturing capabilities for forged golf club head projects. Final specifications are confirmed during project review.

| Weight tolerance | ±1–2 g |

| Loft / Lie tolerance | ±0,5° |

| Groove machining | CNC milled |

| Rugosità superficiale | As specified |

| Batch consistency | Same tooling & controlled process |

| MOQ | Project dependent |

Start Your Forged Golf Club Project

Share your design files, drawings, or samples with us. Our engineering team will review manufacturability and discuss the most reliable production approach for your project.

FAQ

Do you support customer-provided CAD files or samples?

Yes. We manufacture strictly based on customer drawings, CAD files, or physical samples.

What is your MOQ for forged golf club heads?

MOQ depends on design complexity, material, and tooling requirements. Please contact us for project-specific details.

Who owns the tooling?

Tooling is custom-made for each project and belongs to the customer.

Do you offer prototyping before mass production?

Yes. Prototype and pilot runs are supported before full-scale production.

Do you guarantee USGA or R&A compliance?

Compliance requirements must be defined by the customer. We manufacture according to approved designs and specifications.