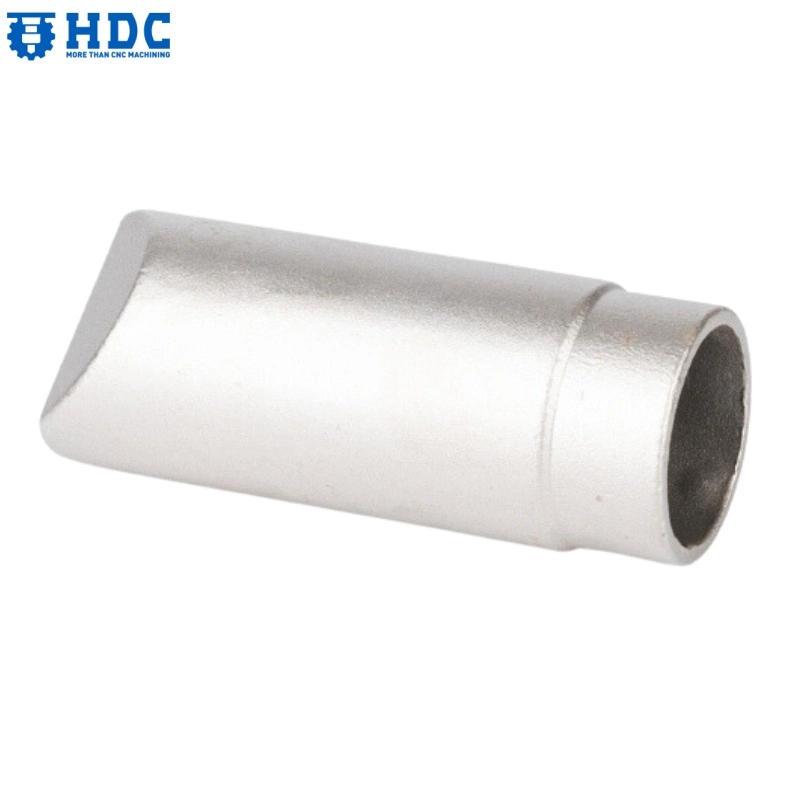

Collettore di scarico per tubo di ritorno a U per fusione a cera persa di parti di automobili personalizzate in acciaio inossidabile

Dettagli del prodotto personalizzato

| Modello numero. | HDCIEH001 |

| Stile | Collettore di scarico per fusione a cera persa |

| Materiale | Alluminio, Lega di alluminio, Acciaio, Lega di acciaio, Acciaio inossidabile, Superlega |

| Tipo di finitura | Grezzo, Lucidato, Anodizzato, Verniciato elettroforeticamente, Verniciato a polvere, Zincato, Cromato, Ossidato nero |

| Misura disponibile | / |

| MOQ | 100 pezzi |

| Logo personalizzato | Disponibile |

| Origine | Cina |

| Imballaggio e consegna | |

| Opzione di spedizione | Corriere, Aereo, Marittimo, Ferroviario Espresso, EXW, FOB, CIF, DDU, DDP |

| Data di consegna | 25-30 giorni |

| Pacchetto di trasporto | Personalizzato, Cartone, Pallet |

Unleash the full potential of your performance exhaust system with this investment-cast U-bend and exhaust header assembly. Precision-engineered for builders and tuners who demand unrestricted flow, thermal integrity, and seamless integration, this one-piece casting eliminates the limitations of fabricated tubing—delivering smooth, high-velocity exhaust evacuation in a single, stress-free component.

Multi-Alloy Customization: Available in stainless steel, high-strength steel alloy, lightweight aluminum, or advanced superalloy—each precision-selected to match your specific thermal load, weight reduction, and corrosion resistance targets.

Investment-Cast Geometric Freedom: Precision investment casting enables complex, merge-optimized flow paths, tight-radius bends, and integrated collector junctions unattainable through traditional mandrel bending or multi-piece welding—eliminating turbulence-inducing seams and failure-prone weld joints.

High-Temperature Structural Integrity: Engineered to withstand extreme thermal cycling and sustained exhaust gas velocities, with alloy-specific heat treatments ensuring long-term dimensional stability, oxidation resistance, and fatigue life.

Optimized Exhaust Scavenging: Continuously radiused internal surfaces and smooth transitional geometry maintain laminar flow characteristics, improving cylinder evacuation, reducing reversion, and delivering measurable gains in torque and horsepower.

Fully Customizable Layout: Manufactured to your exact port spacing, primary tube length, collector configuration, and chassis packaging requirements—ideal for vintage engine retrofits, turbo manifold integration, or one-off performance specials.

Weld-Ready Interface Preparation: Cast-in mounting flanges, O2 sensor bungs, and merge outlets are precision-finished for immediate system integration, reducing fabrication time and ensuring leak-free sealing under pressure.

Applicazioni:

High-Performance Naturally Aspirated Engines: Maximizes torque curves and peak horsepower through precisely tuned primary lengths and merge collector efficiency.

Turbocharged & Forced Induction Systems: Delivers compact, high-flow exhaust routing with minimal pressure drop and superior heat retention for spool characteristics.

Custom & Restomod Exhaust Fabrication: Essential for vintage chassis conversions, prototype development, and motorsport applications requiring non-standard header geometry with verified flow dynamics.

More than a bent tube, this investment-cast header is the fluid-dynamic architect of engine breathing—translating uncontrolled exhaust pulses into organized, high-velocity scavenging with every firing order. Whether you’re chasing peak volumetric efficiency or packaging power into confined spaces, it’s the component that proves optimized flow begins with precision-cast continuity.