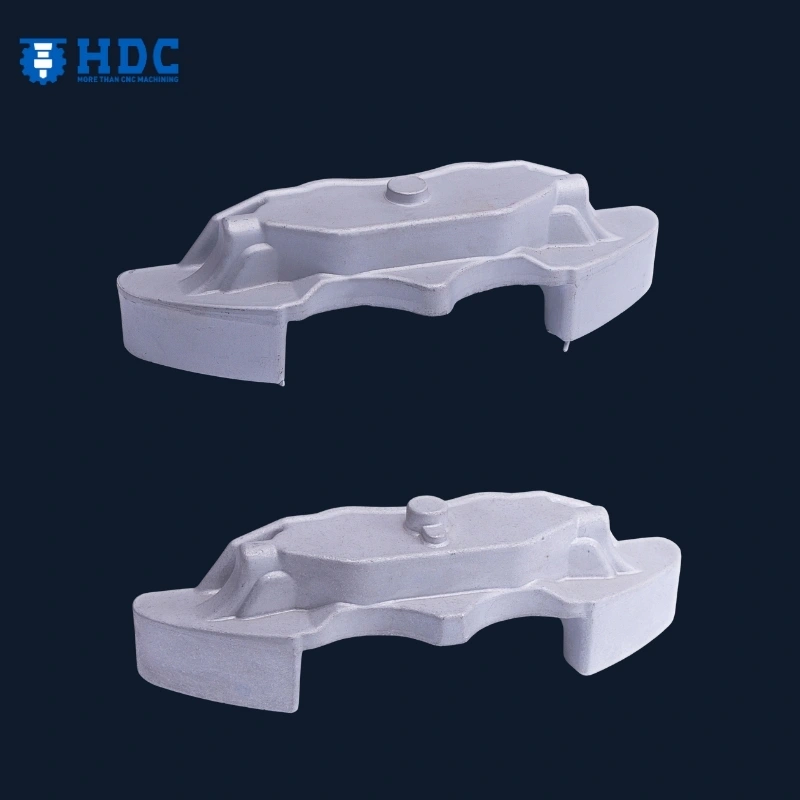

Camma cilindrica con ruota eccentrica forgiata a caldo di precisione in acciaio al carbonio per parti di macchinari

Dettagli del prodotto personalizzato

| Modello numero. | HDCWCC001 |

| Stile | Ruota eccentrica forgiata |

| Materiale | Acciaio al carbonio, lega di acciaio |

| Tipo di finitura | Grezzo, Lucidato, Anodizzato, Verniciato elettroforeticamente, Verniciato a polvere, Zincato, Cromato, Ossidato nero |

| Misura disponibile | / |

| MOQ | 100 pezzi |

| Logo personalizzato | Disponibile |

| Origine | Cina |

| Imballaggio e consegna | |

| Opzione di spedizione | Corriere, Aereo, Marittimo, Ferroviario Espresso, EXW, FOB, CIF, DDU, DDP |

| Data di consegna | 25-30 giorni |

| Pacchetto di trasporto | Personalizzato, Cartone, Pallet |

Questa ruota eccentrica e camma cilindrica forgiata a caldo di precisione garantisce un movimento meccanico preciso sotto carichi ciclici estremi. Progettato per sistemi di automazione e trasmissione ad alto carico, questo componente traduce l'input rotazionale in un output lineare o oscillante accuratamente sincronizzato, con l'integrità del flusso di grano che solo la forgiatura a stampo chiuso può fornire.

Forgiatura in acciaio al carbonio di alta qualità: Fucinato a caldo in acciaio al carbonio di alta qualità, per ottenere un orientamento continuo e ininterrotto della grana che segue il contorno eccentrico e i profili dei lobi delle camme, garantendo una resistenza alla fatica superiore rispetto alle alternative ricavate da billette o fuse.

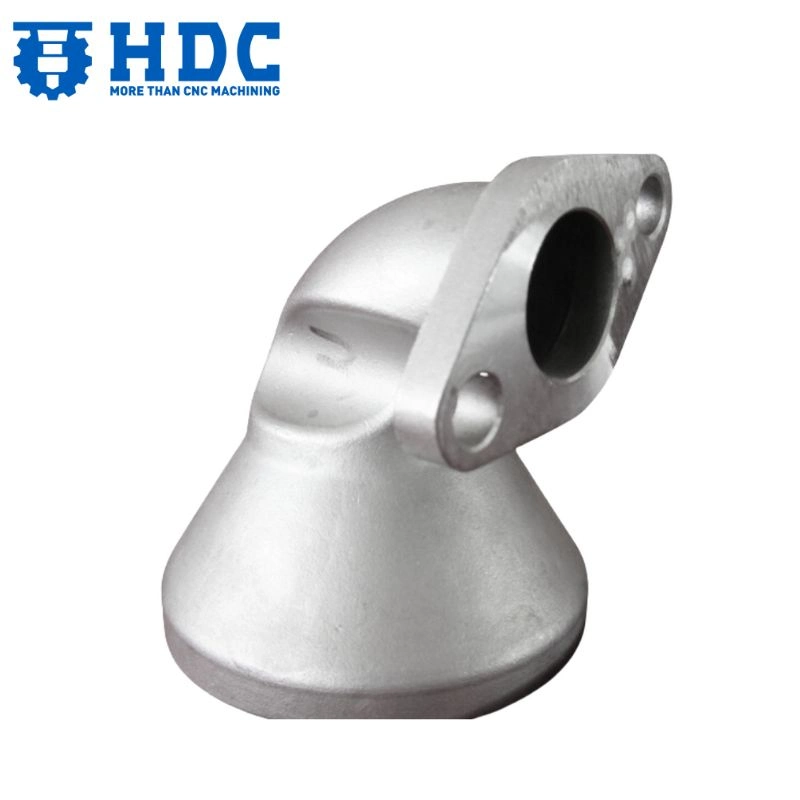

Fedeltà del profilo CNC a 5 assi: Lavorazione di finitura su macchinari CNC a 5 assi per mantenere la massima precisione del profilo, la fasatura dei lobi e le tolleranze di concentricità, fondamentali per un funzionamento ad alta velocità e senza vibrazioni.

Indurimento superficiale disponibile: Disponibile opzionalmente con trattamenti di cementazione, tempra a induzione o nitrurazione, che aumentano significativamente la durata della superficie preservando al contempo la duttilità e la tenacità del nucleo forgiato.

Geometria completamente personalizzabile: Realizzati in base a sviluppi di profili, curve di sollevamento e configurazioni di alesaggio specifici del cliente, soddisfacendo requisiti di temporizzazione non standard, dimensioni di interfaccia e integrazioni di montaggio.

Affidabilità ciclica ad alto carico: Progettato per resistere a urti ripetuti, contatti di scorrimento continui e temperature di esercizio elevate senza scheggiature premature o degrado geometrico.

Applicazioni:

Sistemi di automazione e indicizzazione: Ideale per unità pick-and-place, tavole rotanti e macchinari di assemblaggio azionati da camme che richiedono profili di movimento precisi e ripetibili in cicli di lavoro continui.

Sistemi di trasmissione industriale: Adatto per trasportatori per carichi pesanti, attrezzature per imballaggio e meccanismi di trasmissione specializzati che richiedono un'elevata trasmissione di coppia e un'uscita sincronizzata.

Attuazione meccanica personalizzata: Essenziale per la costruzione di macchinari unici, celle di automazione riadattate o sviluppo di prototipi che richiedono una geometria delle camme non standard e un'integrità dei materiali verificata.

Più di un semplice profilo meccanico, questa camma eccentrica forgiata è l'interprete programmato dell'energia rotazionale, convertendo un input costante in un output dosato con precisione a ogni rotazione. Che si tratti di progettare linee di confezionamento ad alta velocità o attuatori industriali pesanti, è il componente che garantisce che il profilo di movimento rimanga preciso a lungo, anche dopo che componenti minori si sono usurati oltre le specifiche.