Carbon steel, one of the most critical element in modern engineering and industrial applications, derives its unique properties from one key element: carbon. The amount of carbon present in steel plays a pivotal role in determining its performance characteristics, such as strength, ductility, and machinability. This article explores how carbon content influences different types of carbon steel and what it means for real-world applications.

The Importance of Carbon in Carbon Steel

Carbon, as an alloying element, directly affects the microstructure of steel. The interplay between carbon atoms and iron lattices defines the strength, hardness, and other mechanical properties of the material. Whether it’s low-carbon, medium-carbon, or high-carbon steel, the proportion of carbon dictates its suitability for specific tasks.

One of the unique characteristics of carbon steel is its adaptability. By adjusting the carbon content, manufacturers can produce materials that range from highly ductile and malleable to incredibly strong and wear-resistant. This versatility makes carbon steel indispensable across industries, from construction to automotive and even culinary tools.

Categories of Carbon Steel and Their Carbon Content

Acciai al carbonio are classified based on their carbon content, which typically ranges from 0.05% to 1.00%. Each category offers distinct properties, making it suitable for different applications.

Low Carbon Steel (Mild Steel)

- Carbon Content: 0.05% to 0.25%

- Proprietà: Highly ductile and weldable, making it easy to form and machine.

- Typical Grades:

Medium Carbon Steel

- Carbon Content: 0.25% to 0.60%

- Proprietà: Balances strength and ductility, ideal for components requiring toughness.

- Typical Grades:

High Carbon Steel

- Carbon Content: 0.60% to 1.00%

- Proprietà: Incredibly strong and hard but less ductile, requiring careful handling during machining.

- Typical Grades:

Each of these categories offers unique advantages and limitations, making it essential to match the carbon steel type to the specific requirements of the application. The best carbon steel is often a trade-off between the requirements and the cost that goes with adoption of each type of carbon steel.

How Carbon Content Affects Steel Performance

The carbon content in steel is a critical determinant of its mechanical properties. Here’s how it impacts performance:

Strength and Hardness

Higher carbon levels increase the hardness and tensile strength of steel. Carbon atoms form iron carbide (cementite), a hard compound that strengthens the material. For example, high-carbon steel is used in knives and cutting tools for its enhanced hardness.

Ductility and Weldability

While increased carbon content boosts strength, it reduces ductility and weldability. Low-carbon steels, with their lower carbon content, are easier to weld and form without cracking, making them suitable for structural applications.

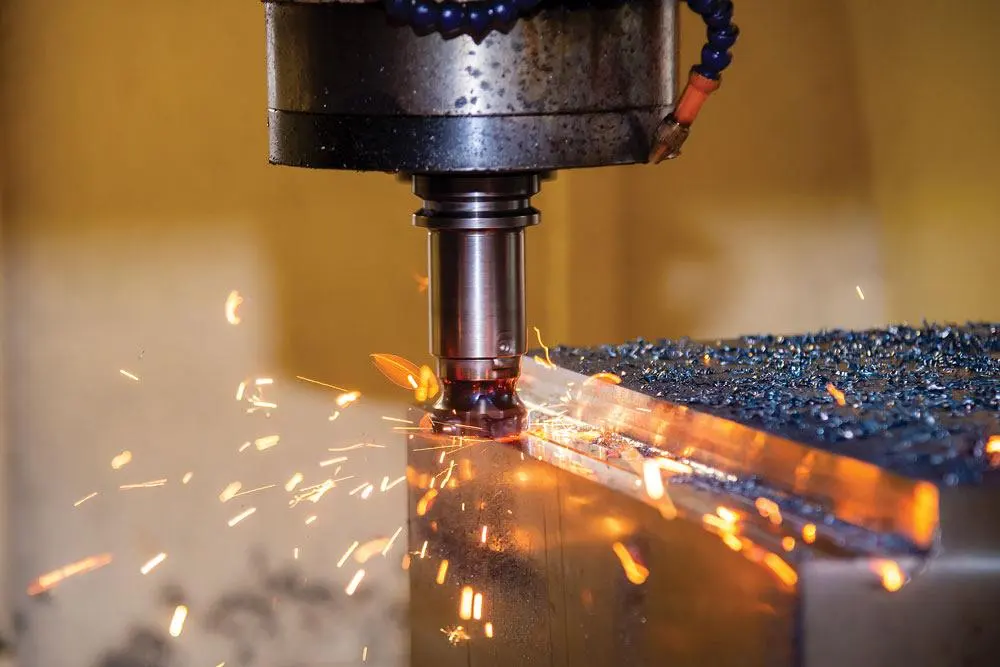

lavorabilità

Steel with higher carbon content tends to be harder to machine. Specialized tools and techniques are often required to work with high-carbon steel, especially in precision applications.

Resistenza alla corrosione

Interestingly, carbon itself doesn’t improve corrosion resistance. In fact, high-carbon steel can be more susceptible to corrosion if not properly treated or alloyed with protective elements like chromium.

Real-World Applications of Carbon Steel

The versatility of carbon steel ensures its presence in numerous industries. Here’s how it’s utilized across various sectors:

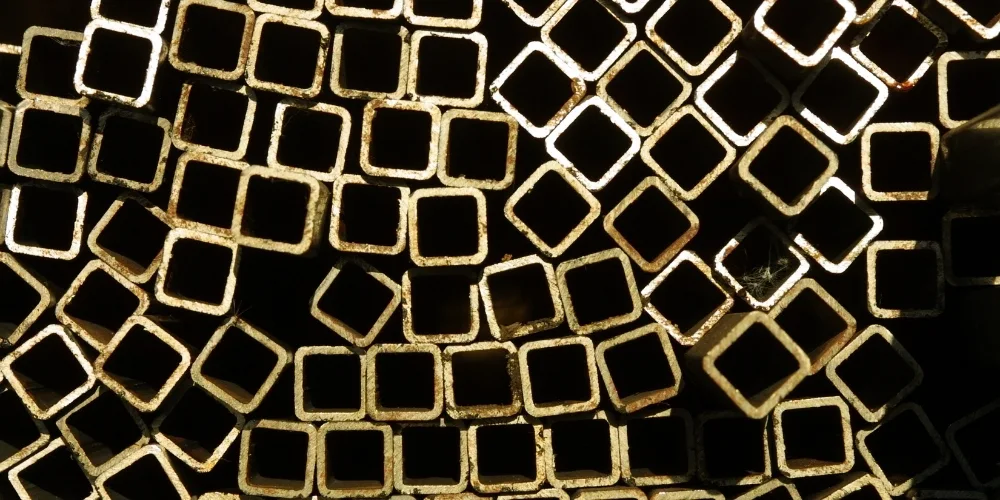

Costruzione

Low-carbon steel is widely used for structural components such as I-beams, columns, and pipelines due to its strength and formability.

Industria automobilistica

Medium-carbon steel is preferred for components like gears, axles, and engine parts, where a balance of strength and ductility is crucial.

Cutting Tools and Equipment

High-carbon steel’s hardness makes it ideal for manufacturing knives, blades, and industrial cutting tools.

Culinary Tools

Carbon steel pans and woks are prized in kitchens for their excellent heat retention and durability, despite requiring more maintenance to prevent rust.

Railway Infrastructure

Medium-carbon steel’s toughness makes it a go-to material for tracks and wheels, where both durability and wear resistance are essential.

Factors to Consider When Choosing Carbon Steel

Selecting the right type of carbon steel requires balancing its properties with the intended application. Here are key factors to keep in mind:

Carbon Content

For welding and forming applications, low-carbon steel is often the best choice due to its ductility and weldability. For applications requiring high strength and wear resistance, medium-carbon or high-carbon steel is more appropriate.

Trattamento termico

Carbon steel’s properties can be further modified through heat treatment processes like annealing, quenching, and tempering. These are especially important for high-carbon steel to optimize its hardness and toughness.

Corrosion Protection

While carbon steel isn’t inherently corrosion-resistant, treatments like galvanizing or painting can help extend its lifespan in corrosive environments.

Comparing Carbon Steel to Other Materials

When considering alternatives to carbon steel, it’s essential to weigh its advantages and limitations. For instance:

- Acciaio inossidabile offers superior corrosion resistance but comes at a higher cost.

- Alluminio is lightweight but lacks the strength and durability of carbon steel.

Among the various types of carbon steels, the choice often comes down to balancing cost, performance, and ease of manufacturing. For example, mild steel is cost-effective and easy to work with, making it suitable for large-scale construction projects. Meanwhile, high-carbon steel, though more expensive and harder to machine, is indispensable for precision tools and heavy-duty applications.

Sustainability and Recycling of Carbon Steel

One of the often-overlooked benefits of carbon steel is its recyclability. Steel is one of the most recycled materials globally, with over 80% of all steel being recycled at the end of its life cycle. This makes carbon steel an environmentally friendly choice for industries aiming to reduce their carbon footprint.

Recycling carbon steel not only conserves natural resources but also requires significantly less energy compared to producing new steel. This aligns with global efforts to promote sustainability in manufacturing and construction.

Conclusione

Carbon is the defining element in carbon steel, shaping its mechanical properties and performance across a range of applications. From the malleability of low-carbon steel to the strength of high-carbon steel, the carbon content dictates how the material behaves under different conditions.

Understanding the relationship between carbon content and steel performance is crucial for selecting the right material for specific needs. Whether it’s for constructing skyscrapers, manufacturing automotive components, or crafting precision tools, carbon steel continues to prove its versatility and reliability.

By balancing carbon content with other factors like heat treatment and corrosion protection, industries can unlock the full potential of this indispensable material. As we move toward more sustainable practices, the recyclability of carbon steel further cements its role as a material of the future.

Scopri di più con i post del nostro blog.

messaggi recenti

Scopri di più sui nostri prodotti.

prodotti correlati

Preventivo immediato!