In this blog, we’ll discuss titanium vs. stainless steel to help you in choosing whether you need one or the other. We will outline each of their differences, what they’re good for, and what expectations you should have from each of them.

Let’s go ahead and compare the two and see what works for you best!

What is Titanium?

Titanio is a lightweight, strong metal known for its exceptional resistance to corrosion and heat. It is naturally found in minerals like ilmenite e rutile and is typically extracted using the Kroll process, which involves chemical reactions to isolate the pure metal.

For its use, it’s used in a lot of different industries, which include:

- Aerospaziale

- Medico

- Industrial

- Settore automobilistico

- Marino

- Gioielleria

- E tanti altri

What is Stainless Steel?

In the simplest words, acciaio inossidabile is a byproduct of chromium alloy and iron. The ratio is at least 10.5% chromium, which makes stainless steel substantially resistant to rust.

This unique combination creates a thin, protective layer on its surface, known as a “passive film,” which prevents damage from moisture and oxygen. Unlike regular steel, stainless steel doesn’t rely on coatings for protection, making it ideal for long-lasting use in harsh conditions.

For their applications, stainless steel is used for a lot of different applications, namely:

- Costruzione

- Kitchenware

- Medical devices

- Trasporti

- E tanti altri

Titanium vs. Stainless Steel: Which Suits You Better?

Normally, we’ll have a table here that outlines their differences for you to see them. However, we want to do a deep dive on specific properties for you to understand it better.

So, let’s put stainless steel and titanium side-by-side and take a look at what makes them different and unique from one another.

Strength Differences

Titanium stands out for its exceptional strength-to-weight ratio. While it’s about as strong as stainless steel, it maintains this strength while being much lighter.

This characteristic makes titanium the go-to material for applications like aerospace and high-performance products.

Stainless steel, however, delivers greater tensile strength. This is what makes it a preferred choice for structural applications that demand durability over reduced weight.

NOTA: In context, the titanium alloy is 20 to 40% stronger than stainless steel.

Il peso

One of titanium’s standout features is its lightweight nature—it weighs nearly 50% less than stainless steel. This is the primary reason why titanium is the go-to industries or products where reducing weight without sacrificing strength is a priority.

Stainless steel, though heavier, adds stability and robustness to products that don’t require portability. They’re heavier and more dense than titanium, making it harder than it.

Titanium is lightweight, and it’s perfect for feather-like activities while maintaining strength. Stainless steel flows on the other end, where hardness and weight are important factors.

NOTA: The density of titanium is 4.5 grams per cubic meter, compared to stainless steel which sits at 7.5 to 8.0 grams per cubic centimeter.

Appearance

Stainless steel is valued for its polished or brushed finish, which offers a shiny, refined look. It’s commonly used in kitchenware, jewelry, and architecture for its sleek and modern style.

Titanium, with its matte or metallic gray finish, has a more understated and futuristic aesthetic, appealing to those seeking minimalistic designs.

Resistenza alla corrosione

In terms of corrosion resistance, titanium outperforms stainless steel. This is true especially in environments like saltwater or chemical exposure.

Titanium forms a reliable and stable oxide layer that protects it from deterioration, even in harsh conditions.

Stainless steel resists rust well in typical environments but can corrode over time when exposed to high chloride levels or extreme conditions.

Price

And lastly, price. We’d all be hypocrites if we say that we don’t mind the price at all. Because titanium is generally more difficult to produce, it’s more expensive.

If we were to look at it per kilogram, titanium costs $35 to $50 more than stainless steel. Stainless steel is generally $1 to $1.50 per kilogram, but can go as high as $4 to $5 for the best and highest quality. It still is a lot less than how much titanium costs.

There you have it! A thorough and deep comparison between titanium and stainless steel!

Grade 5 Titanium vs. 304 Stainless Steel

If there are variants that are considered the most common in these two categories, they’ll be grade 5 titanium and 304 stainless steel.

Because of the strong similarities they have, they’re compared and differentiated the most. So, let us take a look at how they compare with each other.

Factors and Qualities

Grade 5 titanium (Ti-6Al-4V) stands out for its unmatched strength-to-weight ratio. It’s about 40% lighter than 304 stainless steel but nearly twice as strong. This unique balance makes it an irreplaceable product in aerospace, medical implants, and advanced engineering projects.

Acciaio inossidabile 304, on the other hand, is known for its remarkable toughness and ductility. While heavier, it offers the durability required for structural applications, food-grade equipment, and industrial machinery.

Stainless steel’s ability to withstand impact without deforming highlights its practicality in day-to-day applications, whereas titanium’s use is typically reserved for situations demanding high performance with reduced weight.

Applications and Uses

Titanium’s lightweight and biocompatibility make it essential in surgical tools, implants, and lightweight components for aviation.

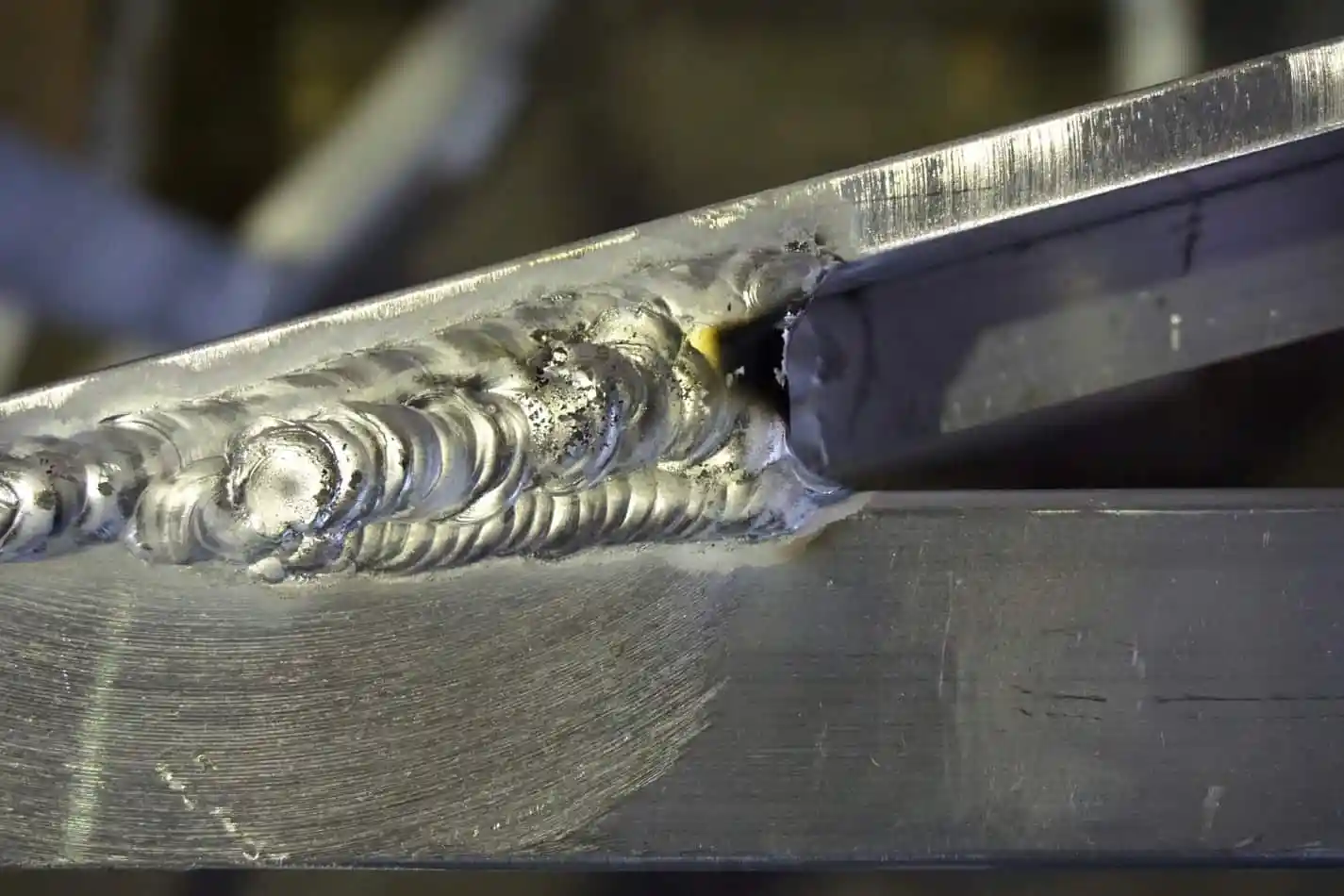

Its non-reactive nature allows it to perform exceptionally in extreme conditions, such as space exploration or deep-sea environments. Meanwhile, 304 stainless steel is favored in kitchens, architecture, and transport industries because of its excellent weldability and hygiene properties.

Stainless steel excels in settings that demand strength and versatility but don’t require the specialized benefits titanium provides.

Pricing

Cost is one of the biggest differences between them, and we’d be lying if we told you that it’s not important. Producing

Grade 5 titanium involves complex extraction and machining, leading to a much higher price tag than 304 stainless steel. Stainless steel, being more abundant and easier to manufacture, is far more economical, making it suitable for large-scale use.

Titanium’s expense limits its applications to niche industries where its properties justify the investment. Imagine the businesses and industries mentioned above, those are the businesses where they’re justified.

Tarnish Resistance

And lastly, their resistance to rust and tarnish. Grade 5 titanium offers exceptional corrosion resistance due to its protective oxide layer, which is self-repairing and highly stable even in saltwater or acidic environments. This makes it ideal for marine and chemical applications.

While 304 stainless steel is also corrosion-resistant, it can develop pitting or crevice corrosion when exposed to chlorides or harsh chemicals over time.

However, for everyday use, stainless steel performs well in humid or mildly corrosive environments, such as kitchens or outdoor furniture.

Why You Can Trust HDC For Any Metal You Need

Titanium vs. stainless steel is one of the industry’s most common questions. But, if you’re wondering where you can get either of these, then you’re just in the right page!

At HDC, we’re committed to providing you with the industry’s best and most reliable titanium steel or stainless steel components.

Whether you’re looking for raw metals or if you need specific parts, we got just what you need! You can count on us if you need metals from titanium steels e stainless steels to copper and aluminum alloys, too!

Reach out to us today and get the best quality of titanium or stainless steel!

Scopri di più con i post del nostro blog.

messaggi recenti

Scopri di più sui nostri prodotti.

prodotti correlati

Preventivo immediato!