Desktop CNC machines have revolutionized the manufacturing world, providing a compact and efficient solution for precision cutting, engraving, and machining. Whether you’re a professional engineer, a small business owner, or an advanced hobbyist, a desktop CNC machine offers the perfect balance of functionality, affordability, and ease of use.

This article will guide you on the Desktop CNC machine features and benefits along with tips for selecting the best one for your needs.

What is a Desktop CNC Machine?

CNC machines have been in use since long, however, the desktop CNC machine provides a compact, computer-driven solution to precisely cut, engrave, or shape a variety of material. Moreover, the variety of materials that you can work with include wood, metal, plastic, and composites. These desktop machines are popular in industries particularly for prototyping, product design, and custom manufacturing.

Also, for hobbyists who create intricate designs or functional components the CNC desktop machines offer a mix of a tool for fulfilling their hobby as well as creating something productive.

Why Choose a Desktop CNC Machine?

Here are a few advantages of desktop CNC machines that can help you deciding whether to go for such a machine or not:

Compact Size and Portability

One of the biggest advantages of desktop CNC machines is their compact size. These machines fit comfortably on a workbench or desk, making them ideal for home workshops, small businesses, or educational institutions with limited space. Accordingly, the portability of the CNC desktop machine is also high and can serve as a creative machine that can be carried from place to place as per convenience.

Precisione e accuratezza

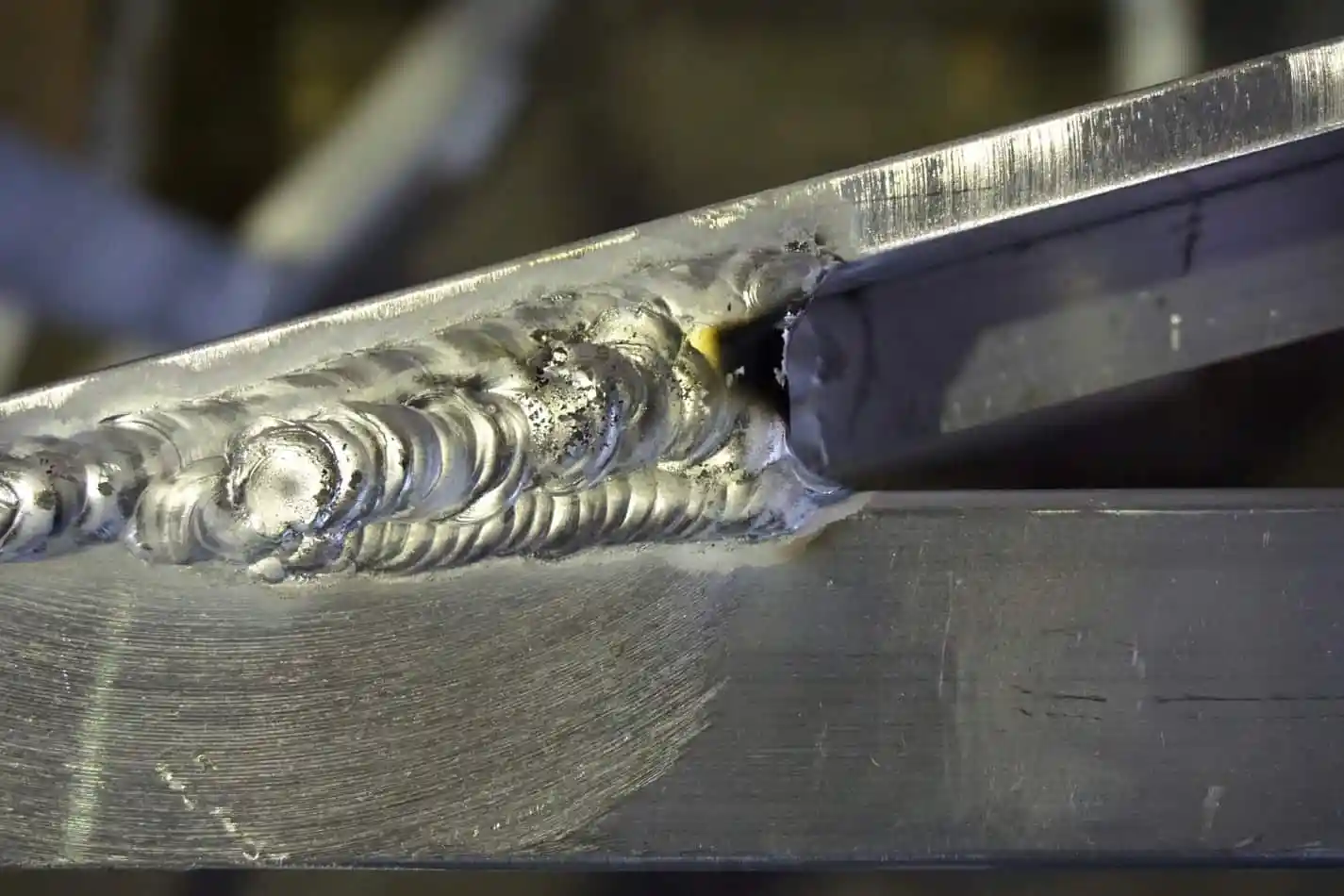

Despite their size, desktop CNC machines are capable of achieving incredible precision, often down to fractions of a millimeter. This makes them suitable for applications requiring high accuracy, such as engraving intricate designs, producing detailed prototypes, or machining small components.

Versatility in Material Processing

From soft woods and plastics to metals like aluminum, desktop CNC machines are versatile enough to handle a wide range of materials. Some advanced models even allow for multi-material machining, enabling greater flexibility in projects.

Facilità d'uso

Intent of the desktop machine is to be used in a domestic/small business environment, therefore, the modern desktop CNC machines come with user-friendly software interfaces that make them accessible to both professionals and newcomers. Many machines feature pre-programmed settings for common materials and operations, simplifying the learning curve.

Efficacia dei costi

Compared to industrial CNC machines, desktop models are much more affordable, with entry-level machines costing a fraction of their larger counterparts. This makes them an excellent investment for small businesses or individual creators looking to add precision machining capabilities to their toolkit.

Applications of Desktop CNC Machines

Desktop CNC machines are used in a variety of industries and by diverse users. Here are some of the most common applications of CNC desktop machines:

Prototyping and Product Development

Engineers and designers often create prototypes of products using desktop CNC machines. The ability to quickly and accurately machine parts allows for faster iteration and testing.

Custom Manufacturing

Small businesses can create custom products from desktop CNC machines such as jewelry, signage, and bespoke furniture.

Educational and Training Purposes

In schools and training centers, desktop CNC machines are used to teach students the principles of CNC programming and machining without the need for large, expensive equipment.

Hobbyist and DIY Projects

From crafting unique wooden sculptures to engraving intricate metalwork, hobbyists can rely on desktop CNC machines for precision and creativity.

Electronics Manufacturing

These machines are also used in the production of circuit boards and other small electronic components, ensuring accuracy in intricate layouts.

Key Features to Consider When Selecting a Desktop CNC Machine

Choosing the right desktop CNC machine requires careful consideration of your specific needs and the machine’s capabilities. Here are the top features to evaluate:

- Size and Workspace: Ensure the machine fits in your workspace without compromising functionality.The size of the work area determines the maximum material size the machine can handle.

- Compatibilità dei materiali: Check the materials the machine can work with. Some are designed for soft materials like wood and plastics, while others can handle metals like aluminum and brass.

- Spindle Power: The spindle’s power affects the machine’s cutting ability. Higher power is essential for tougher materials.

- Software and Compatibility: Look for machines with intuitive software that supports commonly used formats like G-code. Ensure it’s compatible with your operating system and CAD/CAM software.

- Precisione e accuratezza: Pay attention to the machine’s resolution and repeatability. Higher precision ensures better results, especially for intricate projects.

- Facilità d'uso: Choose a machine with an easy-to-navigate interface and pre-configured settings for common materials.

- Durability and Build Quality: Machines with robust frames and components made of steel or aluminum offer better durability and stability during operation.

- Cost and Value: Determine your budget and compare features to ensure you’re getting the best value for your investment.

Popular Desktop CNC Machine Brands

Several manufacturers produce high-quality desktop CNC machines. Here are some brands to consider:

- Carbide 3D: Known for user-friendly machines like the Shapeoko series, suitable for small businesses and professionals.

- Inventables: Their X-Carve line is ideal for hobbyists and light industrial use.

- Tormach: Offers robust, professional-grade machines that combine compact size with industrial-level performance.

- Bantam Tools: Focuses on high-precision desktop CNC for prototyping and small-scale manufacturing.

- Pocket NC: Specializes in compact 5-axis desktop CNC machines, ideal for advanced users.

Diverse Desktop Manufacturing Tools: Meeting the Creative Needs of Different Users

Desktop CNC machines come in a wide variety of types, catering to the needs of different users, from beginners to advanced professionals. For most users, a standard three-axis desktop CNC machine is sufficient to handle basic engraving, cutting, and milling tasks. However, for those seeking higher precision and more complex machining capabilities, there are also high-end five-axis desktop CNC machines available on the market.

Compared to traditional three-axis machines, five-axis desktop CNC machines offer greater flexibility and precision. While the cost of five-axis desktop CNC machines is typically higher than that of standard three-axis models, they offer unparalleled advantages for projects that require extreme precision and multi-angle machining.

In addition to CNC machines, desktop laser cutters, 3D printers, and resin-based (SLA/DLP) 3D printers provide users with even more options for their creative projects. These tools are ideal for cutting, engraving, 3D printing, and creating high-precision models, further expanding the possibilities for design and prototyping. Together with desktop CNC machines, these devices form a diverse ecosystem of tools that can handle projects of varying complexity.

Whether you’re a beginner working on basic tasks or a professional requiring high-precision, complex machining, desktop CNC machines and other desktop manufacturing tools offer a wide range of options to meet the demands of various projects.

Maintenance Tips for Desktop CNC Machines

To keep your desktop CNC machine running smoothly and extend its lifespan, follow these maintenance practices:

- Pulizia regolare: Remove dust and debris from the machine after every use.

- Lubrificazione: Keep moving parts lubricated to reduce wear and tear.

- Check Connections: Ensure all cables and components are securely connected.

- Inspect Spindles and Tools: Replace worn tools or spindles as needed to maintain accuracy.

- Software Updates: Regularly update the software to access new features and bug fixes.

Desktop CNC Machines vs. Industrial CNC Machines

While desktop CNC machines offer significant advantages, it’s important to understand their limitations compared to industrial CNC machines:

Caratteristica | Desktop CNC Machines | Industrial CNC Machines |

Dimensione | Compact, fits on a workbench | Large, requires dedicated floor space |

Costo | Affordable (often below $5,000) | Expensive (often above $50,000) |

Material Capability | Limited to lighter materials | Can handle tougher materials like steel |

Precisione | High for small-scale projects | Extreme precision for large-scale projects |

Applicazioni | Prototyping, custom manufacturing | Mass production, heavy-duty applications |

Conclusione

Desktop CNC machines are an invaluable tool for professionals, small businesses, and advanced hobbyists alike. Their compact size, versatility, and precision make them ideal for a variety of applications, from prototyping and custom manufacturing to intricate design work. When selecting a desktop CNC machine, consider factors like material compatibility, precision, ease of use, and cost to find a model that best suits your needs.

By investing in a reliable desktop CNC machine, you can streamline production, achieve superior results, and unlock new possibilities in your creative or professional projects.

Scopri di più con i post del nostro blog.

messaggi recenti

Scopri di più sui nostri prodotti.

prodotti correlati

Preventivo immediato!