تصنيع قطع معدنية مخصصة متكاملة في الصين

قم بتبسيط سلسلة التوريد الخاصة بك من خلال عمليات التصنيع المتكاملة، بما في ذلك التصنيع باستخدام الحاسب الآلي، والصب، والتشكيل، والمزيد.

🛡️ يتم الحفاظ على جميع المحتويات التي يتم تحميلها آمنة وسرية.

القدرات الأساسية

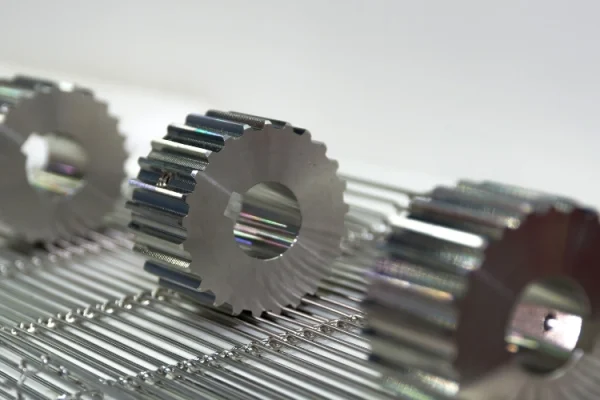

التصنيع باستخدام الحاسب الآلي

- مجهز بـ 3 محاور, 4 محاور، و 5 محاور مراكز التصنيع باستخدام الحاسوب (CNC).

- تفاوت دقيق يصل إلى ±0.005 مم.

- تشطيب الأبعاد الحرجة للمسبوكات والمطروقات باستخدام آلات CNC.

- التحكم في الأبعاد الحرجة.

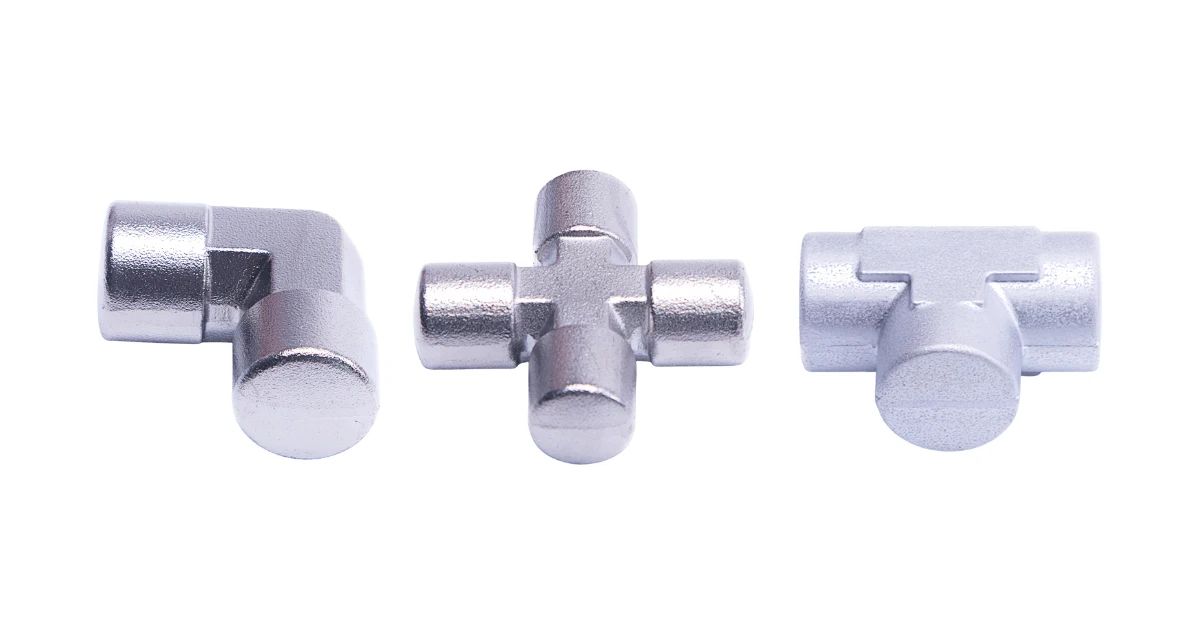

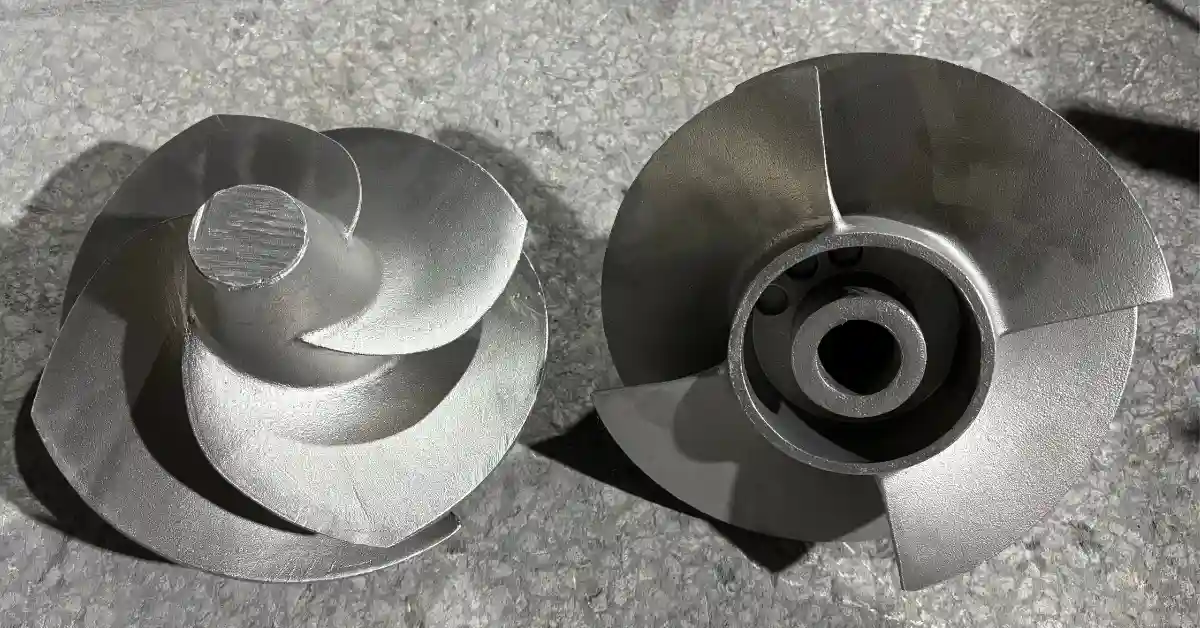

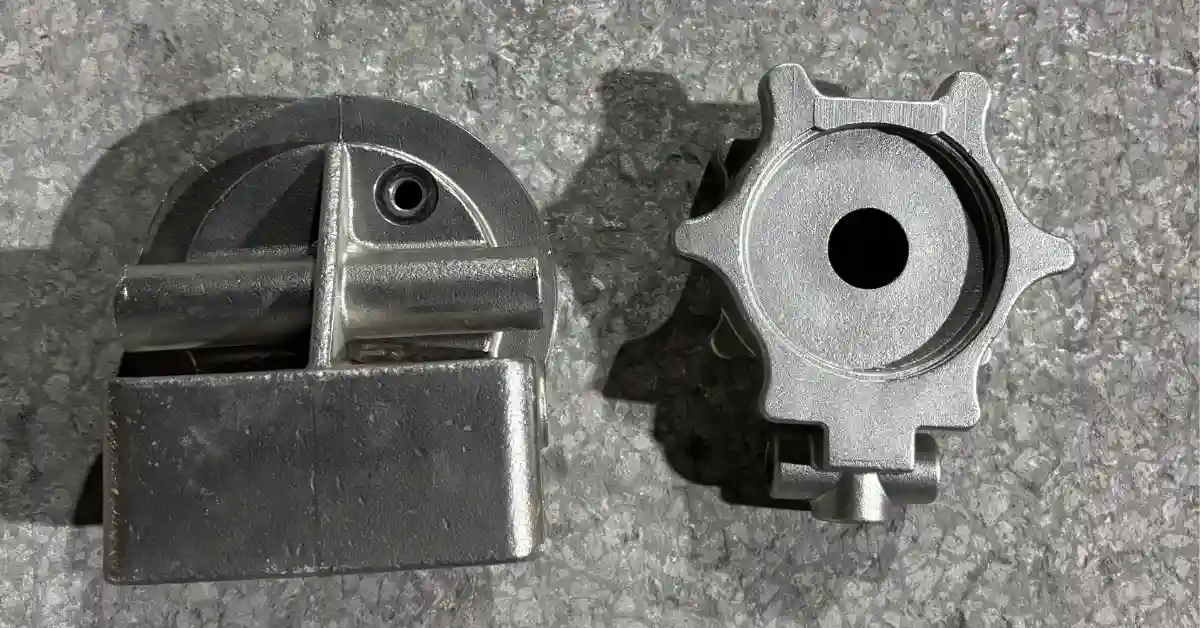

صب

- صب دقيق مع الفولاذ المقاوم للصدأ, سبيكة النيكل, وغير ذلك.

- 50 كجم أقصى عدد ممكن من عمليات الصب الفردية.

- دقة عالية في التشطيب باستخدام تقنية CNC.

- حلول مخصصة في عمليات الصب, تكوين المواد، و المعالجة الحرارية.

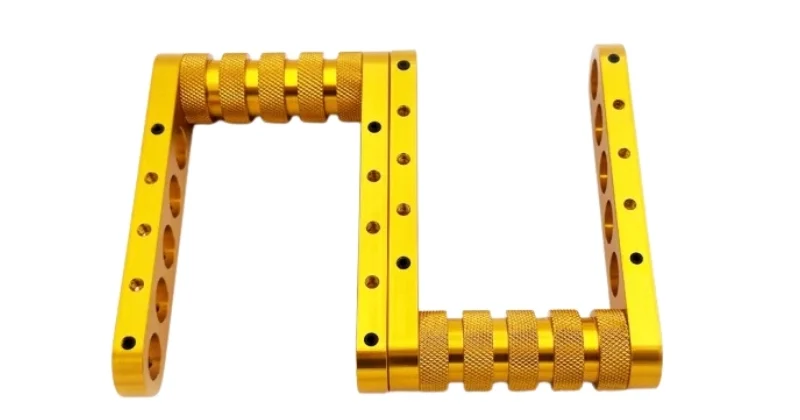

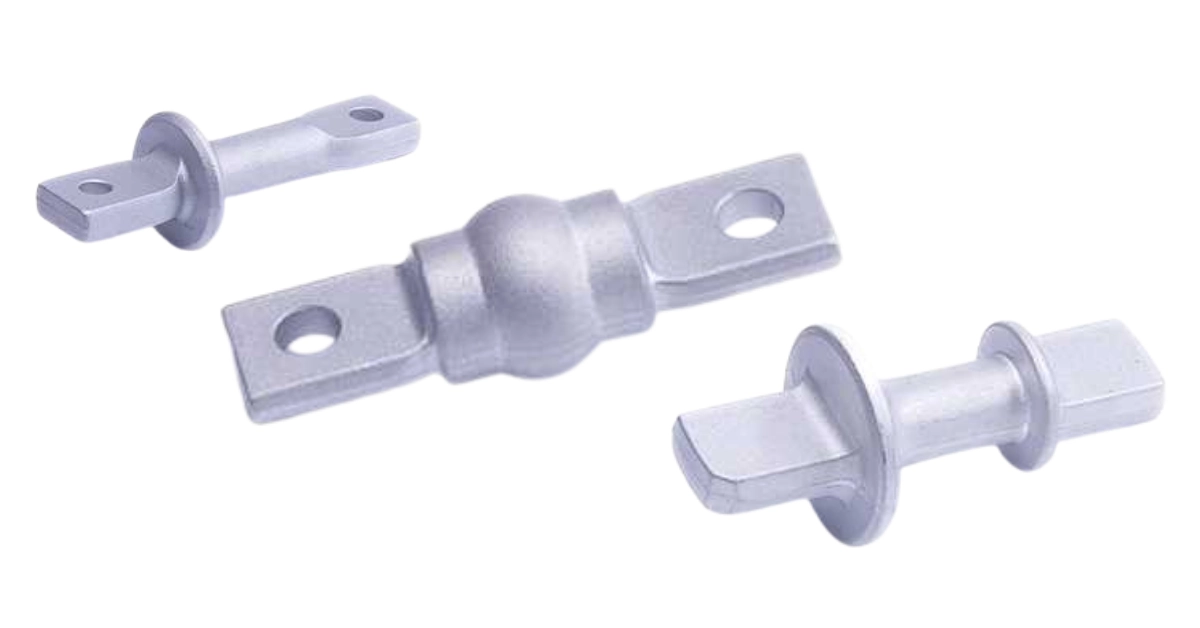

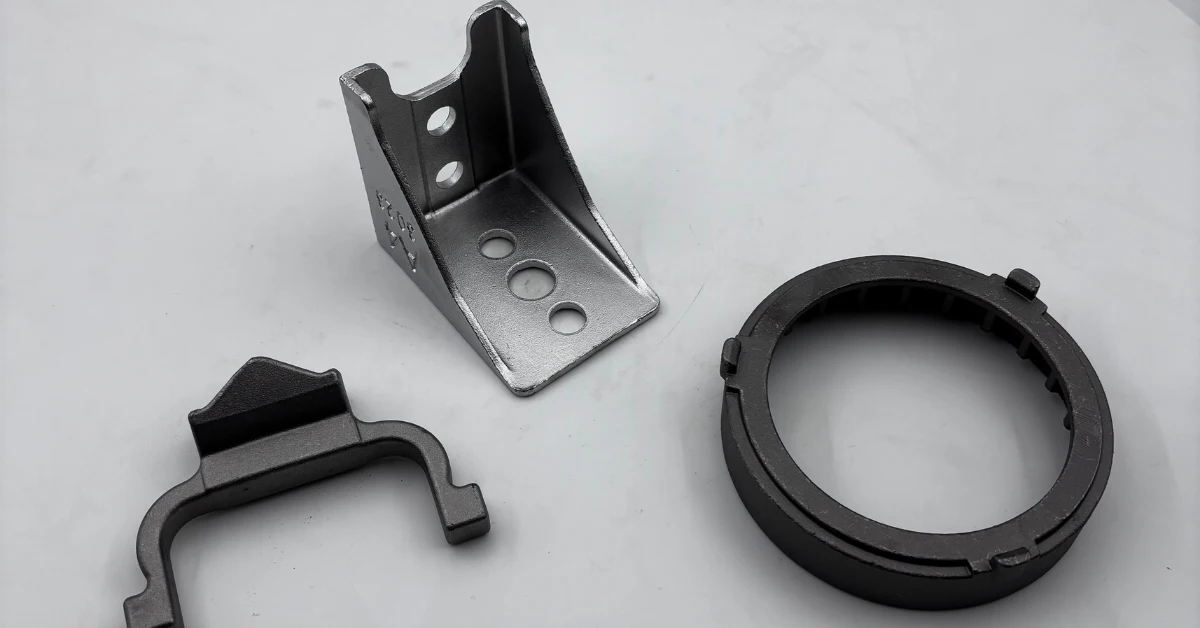

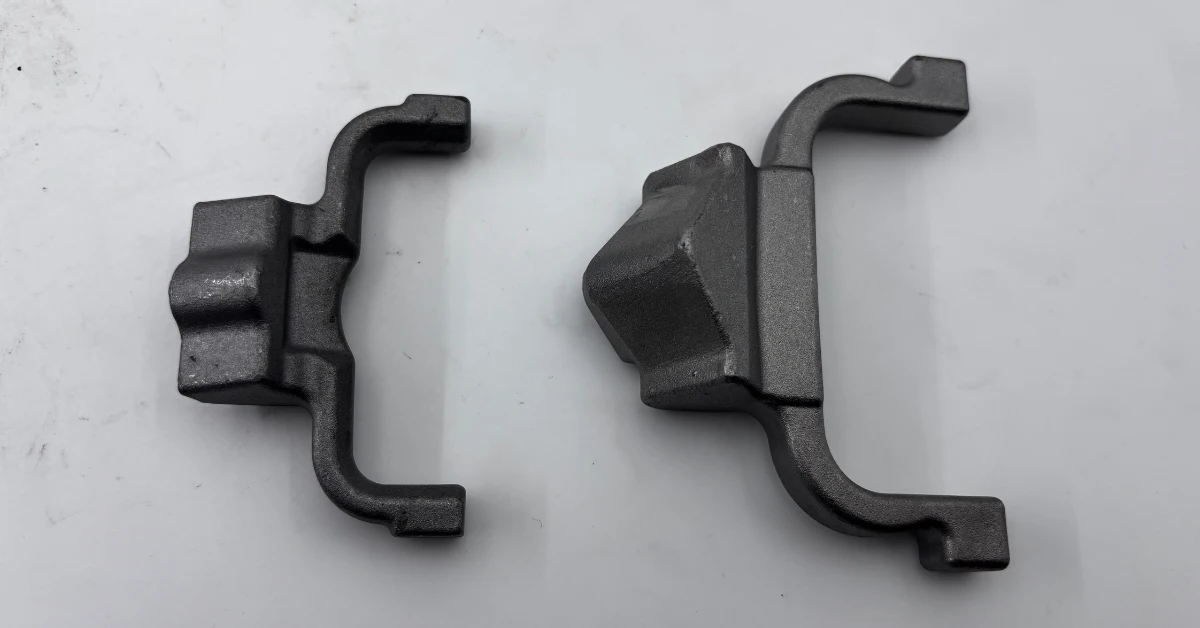

تشكيل

- التشكيل باستخدام سبائك الألومنيوم،, الفولاذ الكربوني, والفولاذ المقاوم للصدأ.

- 30 كجم أقصى قدر من التشكيل الفردي.

- 160 طن ~ 4000 طن مكابس الحدادة ومكابس البراغي.

- تتوفر عمليات التشكيل على البارد والتشكيل على الساخن.

الخدمة العالمية

لقد خدمنا أكثر من 1000 عميل من أكثر من 50 دولة.

حاصل على شهادة ISO وIATF

لدينا شهادة ISO9001:2005.

أكثر من 50 مادة معتمدة

يمكننا تخصيص قطعك المعدنية بأكثر من 50 نوعًا مختلفًا من المواد

التسليم في الموعد المحدد

سيتم تسليم الأجزاء إليك كما وعدنا، من أسبوع إلى 30 يومًا.

لمزيد من المعلومات، يرجى زيارة موقعنا سياسة الخدمة صفحة.

لماذا تختار شركة HDC للتصنيع؟

أكثر من مجرد شركة مصنعة: شريكك في الهندسة وسلسلة التوريد

قد يكون المشروع الحقيقي معقدًا، وقد يتطلب دمج عمليات تصنيع متعددة لإنتاج المكونات المطلوبة. بالنسبة لمصنعي العلامات التجارية، قد تصبح إدارة موردين متعددين عبر عمليات مختلفة أمرًا معقدًا ومحفوفًا بالمخاطر بسرعة.

بدأنا كورشة تصنيع باستخدام الحاسوب (CNC)، وواصلنا إثراء قدراتنا في التصنيع وتطوير سلسلة التوريد الخاصة بنا، بهدف توفير حل متكامل لعملائنا.

بفضل خبرتنا الأساسية في مجال التصنيع باستخدام الحاسوب (CNC)، نجمع أفضل موارد التصنيع في الصين في مجالي الصب والتشكيل ضمن نظام جودة واحد موثوق. بدءًا من الهندسة والتوريد وصولًا إلى مراقبة الجودة والخدمات اللوجستية، نتولى جميع الجوانب المعقدة، لتتمكن من التركيز على منتجك لا على مورديك.

ارتقِ بعلامتك التجارية من خلال حلول مخصصة

في شركة HDC للتصنيع، لا نقتصر على التصنيع فحسب، بل نعمل كشريك عملي وفعّال لمساعدتك في تحويل أفكار منتجاتك إلى واقع ملموس. بدءًا من الأفكار الأولية وصولًا إلى المكونات النهائية، ندعم تصنيع قطع معدنية مخصصة وعمليات تشغيل دقيقة للعلامات التجارية الناشئة والراسخة على حد سواء.

بفضل عمليات التصنيع المتكاملة باستخدام الحاسوب (CNC) والصب والتشكيل، نساعدك على التحرك بشكل أسرع، وتقليل تعقيد سلسلة التوريد، وتحقيق جودة متسقة - حتى تتمكن من التركيز على بناء علامتك التجارية، وليس إدارة الموردين.

عملية الطلب

الاستشارة الأولية

شارك متطلبات مشروعك مع فريقنا. سنراجع طلبك ونقدم لك نصائح هندسية عملية لمساعدتك على البدء.

تقديم التصميم

أرسل لنا ملفات التصميم الخاصة بك، أو اعمل مع مهندسينا لتحسين التصميم من أجل سهولة التصنيع وكفاءة التكلفة.

عرض الأسعار ومراجعة التصميم

ستتلقى عرض أسعار واضحًا ومفصلاً بالإضافة إلى مراجعة نهائية لجميع المواصفات قبل المضي قدمًا.

تطوير النموذج الأولي

عند الحاجة، نقوم بإنتاج نماذج أولية للتحقق من صحة التصميم والملاءمة والأداء قبل الإنتاج الضخم.

الإنتاج ومراقبة الجودة

بمجرد الموافقة، يبدأ الإنتاج على نطاق واسع، مدعومًا بعمليات تفتيش أثناء العملية ومراقبة صارمة للجودة في كل مرحلة.

الشحن والتسليم

اختر طريقة الشحن التي تفضلها. نوفر خدمة التوصيل إلى جميع أنحاء العالم مع ضمان مواعيد تسليم موثوقة.

يمكنك الوصول إلى مواردنا لمعرفة المزيد عن إمكانيات مركز البيانات البشرية.

المواد المعدنية التي نتعامل معها

تتعامل شركة HDC Manufacturing مع مجموعة واسعة من المواد المعدنية لتلبية متطلبات القوة والوزن والأداء المختلفة.

خيارات معالجة الأسطح الشاملة

بفضل عمليات التشطيب السطحي المتكاملة داخل الشركة وسلسلة التوريد الموثوقة للمعالجة اللاحقة، توفر شركة HDC Manufacturing مجموعة كاملة من المعالجات السطحية لتحسين المظهر والمتانة والأداء الوظيفي للأجزاء المعدنية المصممة حسب الطلب.

| 🔷 السفع الرملي | 🔷 تفجير الخرز |

| 🔷 أنودة من النوع الثاني | 🔷 أنودة من النوع الثالث |

| 🔷 طلاء المسحوق | 🔷 الرسم |

| 🔷 طلاء الزنك | 🔷 طلاء الكروم |

| 🔷 النقش بالليزر | 🔷 أكسيد أسود |

المعالجة الحرارية للأجزاء المعدنية

تلعب المعالجة الحرارية دورًا حاسمًا في تحقيق القوة والصلابة والمتانة المطلوبة للأجزاء المعدنية.

بفضل عمليات المعالجة الحرارية الخاضعة للتحكم وسلسلة التوريد الموثوقة لما بعد المعالجة، فإننا ندعم مجموعة كاملة من خيارات المعالجة الحرارية لتحسين خصائص المواد لتطبيقات مختلفة.

| 🔷 إخماد | 🔷التلطيف |

| 🔷 التلدين | 🔷التطبيع |

| 🔷 علاج محلول |

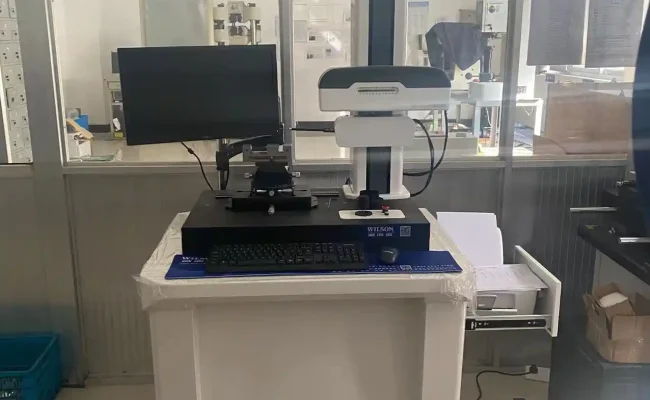

ضبط الجودة

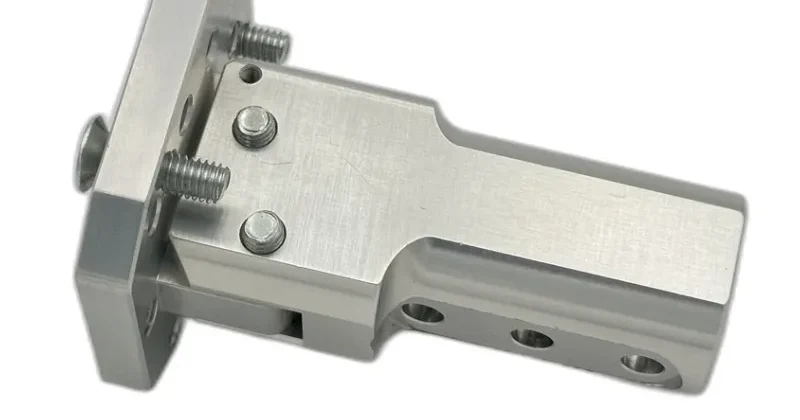

منتجات مصنعة حسب الطلب

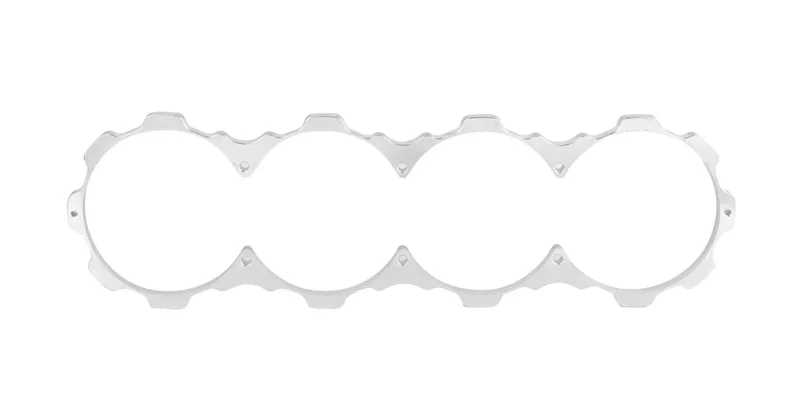

مكونات مطروقة ومصبوبة ومصنعة باستخدام آلات CNC للعديد من الصناعات

مكونات السيارات المطروقة

مكونات الدراجات النارية المصنعة بالتشكيل

ملحقات عجلة القيادة والعجلات

مكونات هيكلية وأدوات مصنعة بالتشكيل

الأدوات والأقواس والوصلات

مكونات الصب الصناعية

جسم المضخة، الصمام، غلاف التروس

قطع غيار السيارات المصبوبة

قطع غيار السيارات والدراجات النارية والدراجات الهوائية والدراجات الكهربائية

أدوات ومسبوكات هيكلية

الموصلات والأقواس والأجهزة المخصصة

قطع غيار السيارات المصنعة باستخدام تقنية CNC

ماذا يقول عملاؤنا

الأسئلة الشائعة

كل ما تحتاج لمعرفته قبل العمل مع شركة HDC Manufacturing.

كيف يمكنني أن أطلب عرض أسعار؟

لطلب عرض سعر، ما عليك سوى مشاركة تفاصيل مشروعك معنا، بما في ذلك الرسومات ومتطلبات المواد وأي مواصفات خاصة. سيقوم فريقنا الهندسي بمراجعة معلوماتك وتقديم عرض سعر واضح ومفصل في أسرع وقت ممكن.

ما هي المهلة الزمنية النموذجية للطلبات المخصصة؟

تختلف مدة التسليم تبعًا لمدى تعقيد القطعة وكميتها وعمليات التصنيع. بالنسبة لمعظم المشاريع المصممة حسب الطلب، يمكن إتمام الإنتاج في غضون أسابيع قليلة. يتم تأكيد مدة التسليم المقدرة خلال مرحلة تقديم عرض الأسعار.

ما هي خيارات الشحن المتاحة؟

نقدم خيارات شحن مرنة، تشمل الشحن الجوي والبحري والتوصيل السريع. تتوفر خدمة الشحن الدولي، ويمكن ترتيب شروط التسليم على ظهر السفينة (FOB) وفقًا لمتطلباتكم.

كيف تضمن شركة HDC Manufacturing جودة منتجاتها؟

تُضبط الجودة في كل مرحلة من مراحل الإنتاج. بدءًا من فحص المواد الخام وصولًا إلى عمليات الفحص أثناء التصنيع والفحص النهائي، يدعم نظام الجودة لدينا شهادة ISO لضمان الاتساق والموثوقية في كل طلب.

هل يوجد حد أدنى لكمية الطلب (MOQ)؟

يعتمد الحد الأدنى لكمية الطلب على نوع المنتج والمادة المصنعة وعملية التصنيع. ندعم أحجام إنتاج مرنة، ونشجعكم على التواصل معنا لمناقشة الحل الأمثل لمشروعكم.

هل يمكن لشركة HDC Manufacturing المساعدة في التصميم أو النماذج الأولية؟

نعم. نحن نقدم الدعم الهندسي وخدمات النماذج الأولية للمساعدة في تحسين تصميمك من حيث قابلية التصنيع والأداء والتكلفة قبل الإنتاج الضخم.

ما هي طرق الدفع التي تقبلونها؟

نقبل طرق الدفع الآمنة، بما في ذلك التحويلات البنكية، وباي بال، وغيرها من الخيارات الشائعة. يتم تأكيد شروط الدفع أثناء عملية الطلب لضمان الوضوح والشفافية.

هل تقدمون الدعم للمستوردين لأول مرة؟

نعم. نحن نعمل بانتظام مع المستوردين الجدد ونقدم لهم إرشادات حول مصطلحات التجارة الدولية (Incoterms) والتخليص الجمركي وخيارات الشحن للمساعدة في ضمان عملية استيراد سلسة.

كيف يمكنني الاتصال بشركة HDC Manufacturing للحصول على مزيد من المعلومات؟

يمكنكم التواصل معنا عبر صفحة الاتصال، أو البريد الإلكتروني، أو الهاتف. فريقنا جاهز لمناقشة مشروعكم والإجابة على أي استفسارات لديكم.

دعنا نحول تصميمك إلى واقع

قم بتحميل رسوماتك الفنية (STEP أو IGES أو PDF) للحصول على تعليقات احترافية حول تصميم التصنيع (DFM) وعرض أسعار تنافسي في غضون 24 ساعة.

* مراجعة هندسية متاحة. يمكن توقيع اتفاقية عدم الإفصاح عند الطلب.