China Customized Forged Eye Bolt Manufacturer

As a forging factory, HDC provides comprehensive customization service for your project. From high-demand automotive parts to small hardware, you can count on our expertise.

Types of Eye Bolt HDC Forge

HDC fabricates a wide range of eye bolts available on the market and also offers custom services.

Non Shouldered Eye Bolt

The non-shouldered style is the most common eye bolt type. It’s simple and suitable for lifting or fixing applications requiring high strength. HDC forges it with high-quality material to ensure stability in heavy-duty applications.

Shouldered Eye Bolt

Shouldered eye bolt, which visually resembles a combination of a bolt and a ring. Depending on the mounting and loading requirements, HDC can produce it in different types, including part thread and full thread.

Swivel Eye Bolt

The biggest benefit of the swivel eye bolt is that it allows the eye to rotate 360° parallel to the mounting surface. This provides a flexible lifting operation without carefully adjusting the angle.

Oval Eye Bolt

Different from the traditional round eye bolt, you can tell from its name that it has an oval eye. This allows a balanced load distribution. HDC forges the oval eye bolt in one-piece type to further enhance its load capacity.

Triangle Eye Bolt

This eye bolt features a triangle-shaped eye and is primarily used for lifting and securing applications with webbing or flat rope. You can customize it with different materials, features, and specifications at HDC.

Open Eye Bolt

An open eye bolt, also known as a hook eye bolt, can be approximately regarded as created by cutting a notch near the bottom of the eye bolt’s ring. It’s used for quickly securing and releasing in lightweight applications

Long Shank Eye Bolt

As the name suggests, this eye bolt has nothing different from a standard eye bolt but a long shank. This helps it embed more deeply into the mounting surface, allowing it to bear a heavier load. HDC can help build the shank to any length you need.

Screw Thread Eye Bolt

There are two types of threads on an eye bolt: machine threads and self-tapping threads. Machine-threaded eye bolts are used with a nut or inserted into a pre-threaded hole, while self-tapping eye bolts are designed for direct installation into wood or other soft materials.

Weld On Eye Bolt

The weld-on eye bolt is a fixed hardware that requires careful welding installation. It’s also the best choice for a permanent, heavy-duty load-lifting application. At HDC, we fabricate it with high-strength carbon steel and alloy steel for industrial lifting requirements.

لماذا تختار HDC

Why should you trust HDC for a custom-built eye bolt? Here is the answer.

Near-Net Shape Forging

HDC offers close-die forging to fabricate the eye bolt, which can produce the eye bolt that barely needs machining except for threading.

مجموعة واسعة من المواد

HDC provides carbon steel, alloy steel, stainless steel, and aluminum for your custom eye bolt. We can also negotiate on materials not on our list.

فعالة من حيث التكلفة

Our comprehensive in-house manufacturing capabilities include mold manufacturing & testing, forging, heat-treatment, and CNC finishing. Finally leads to a competitive price on the market.

خدمة شاملة

Purchasing from HDC is as easy as buying from a local. We offer design support, multilingual support, multiple shipping terms, and after-sales service.

How HDC Fabricates Eye Bolt

Get a clear understanding of how HDC fabricates the eye bolt from raw material.

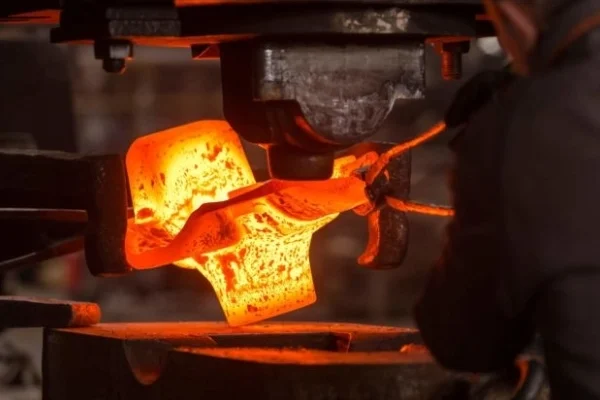

تشكيل

Close die forging is our primary forging method. Equipped with both forging press and screw press, HDC offers hot forging and cold forging depending on specific material and product requirements.

المعالجة الحرارية

As hardware that needs to withstand high loads, we deeply understand the importance of heat treatment for eye bolts. HDC offers a series of heat treatments, including tempering, quenching, etc.

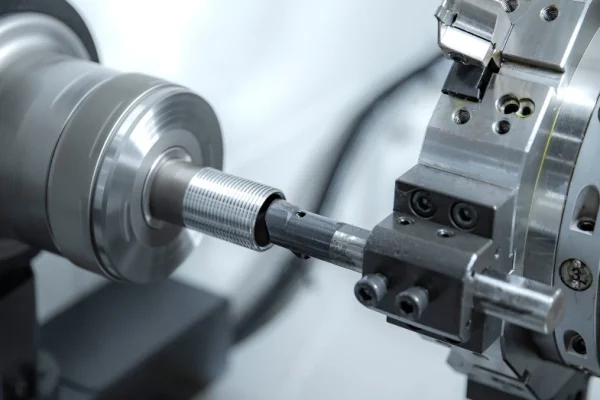

Drilling and Threading

Typically, this is the last step in manufacturing an eye bolt. With the 40+ 3-axis and 4-axis CNC machines we possess, this step is undertaken in-house with unparalleled efficiency.

تحقق من موقعنا ضبط الجودة methods for forging parts.

Available Materials

Check out the materials we offer for your customized projects.

HDC offers both carbon steel and alloy steel. The grades include س355ب, س235, 20#, 45#, 20 كرور, 20CrMo, 40 كرور، و 42 الكرومومو.

Their prices vary. Typically, carbon steel is the most cost-effective choice for an eye bolt build for a heavy-duty load, but it always needs surface finishes to enhance corrosion resistance. In contrast, alloy steel is more expensive due to the addition of elements that enhance specific properties.

Confusing with material selection? You can email us your application and budget, and HDC can help you choose the material that is most suitable for your project.

We all know the benefits of stainless steel: corrosion resistance, shiny appearance, exceptional strength, etc. However, better means more expensive. We don’t recommend it unless you are going to use it in marine or harsh environments.

Common grades HDC provides include 304, 316، و 1.4571. Relying on China’s strong stainless steel production capacity, we can purchase raw material at the lowest price in the world. Combined with our years of expertise in forging stainless steel, we are confident in offering you the best stainless steel eye bolt.

The aluminum eye bolt is valued for lightweight, low-load applications. As a forging factory, this is the material we deal with most.

The common grades we offer include 2A50, 2014, 6061, 6063, 6082, and 7075.

The density of titanium is about half that of steel, while its strength is greater than that of most steel. Eye bolts made of forged titanium are primarily used in extreme environments, where they must withstand high temperatures, heavy loads, and severe corrosion, such as in aerospace and deep ocean.

The titanium grades HDC offers include Ti-6Al-4V, Ti-6Al-4V ELI, and Ti-3Al-2.5V.

Custom Surface Finishes

HDC fabricates and finishes the product with comprehensive in-house capabilities.

Galvanizing is a common finish for steel to enhance its weather resistance. HDC offers both hot-dip galvanizing and electric galvanizing for different surface requirements.

Polishing and passivation can be applied to the stainless steel eye bolt for better corrosion resistance and appearance. They can also be used as a pre-process for the next surface treatment process. HDC will choose the proper surface treatment to achieve the function and appearance you require.

For aluminum and titanium eye bolts, HDC offers both color anodizing and hard anodizing. You can choose a different color to match your brand’s style or opt for hard anodizing for an improved surface quality.

المواصفات الفنية

Get a full understanding of our manufacturing capabilities before requesting a quote.

| Forging Type | Closed-die forging for eye section + integrated forged shank |

| Eye Outer Diameter (ØC) | Customizable: 16 mm – 60 mm (or per drawing) |

| Eye Cross-Section Diameter (ØD) | 5 mm – 20 mm depending on load rating |

| Shank Diameter / Thread Size | M6 – M36 (Metric) / 1/4″ – 1-1/4″ (Imperial) |

| Shank Length (L) | 12 mm – 120 mm (or extended long-shank version) |

| نوع الخيط | Machine thread / Self-tapping / UNC / UNF / BSW |

| طول الخيط | Partial or full thread options |

| نطاق وزن التشكيل | 0.05 kg – 30 kg per piece depending on model |

| المعالجة الحرارية | Normalizing / Quenching & Tempering / Solution + Aging (Al/Ti) |

| معالجة السطح | HDG, zinc plating, passivation, polishing, black oxide, anodizing |

| Load Rating Options | Working load ≈ 1/4 of breaking load; custom load testing available |

| Breaking Load (B.L.) | Based on material & size; up to 10–30 kN for typical forged types |

| Tolerance (After CNC) | ±0.2 mm for critical areas |

| التصنيع | CNC machining for thread, shank, and contact surfaces |

| Inspection & Testing | Tensile test, hardness test, thread gauge inspection, CMM check |

| Design Support | 2D/3D drawing optimization, material selection, load analysis |

| حجم الإنتاج | Small batch to mass production (MOQ depends on size & material) |

Need to build a Custom Eye Bolt?

تواصل مع HDC لتحصل على أفضل حلول التشكيل المتكاملة. أرسل بريدًا إلكترونيًا، واحصل على عرض سعر مجاني!

التعليمات

What is an eye bolt, and what is it used for?

An eye bolt is a fastener with a circular loop on one end and a threaded shank on the other. It’s commonly used for lifting, pulling, anchoring, and securing loads. You’ll see them in machinery, construction, marine hardware, and many industrial setups.

What is a shoulder eye bolt?

A shoulder eye bolt has a flat “shoulder” between the eye and the shank. This shoulder gives it better support, allowing it to handle loads from different angles—not just straight upward. It’s the preferred choice for lifting applications where side loading may occur.

What is a swivel eye bolt?

A swivel eye bolt has a rotating ring or head that can turn freely. It prevents the lifting line from twisting and helps keep the load stable. Swivel eye bolts are ideal for dynamic lifting or situations where the load may rotate.

What are the different types of eye bolts?

Common types include:

- Shoulder eye bolt (for angular lifting)

- Non-shoulder eye bolt (straight lift only)

- Swivel eye bolt

- Long-shank eye bolt

- Open or hook eye bolt

- Lag/screw eye bolt (for wood)

- Collared eye bolt

HDC can produce all of these in forged form or per customer drawing.

How much weight can an eye bolt hold?

Load capacity depends on the size, material, and structure. As a general rule, the safe working load is 1/4 of the breaking load. For forged steel or stainless-steel eye bolts, capacities can range from a few hundred kilograms to over 10 tons.

HDC can also perform load testing if required.

What is the difference between an eye bolt and a ring bolt?

They look similar, but the ring bolt uses a separate ring attached to the body, giving it more movement and flexibility. An eye bolt has an integrated forged eye, which is stronger and better for controlled lifting.

Can you weld an eye bolt?

Welding is not recommended for lifting eye bolts because it may weaken the metal structure. Forged one-piece eye bolts are always safer and stronger.

If the application is non-lifting, HDC can manufacture weld-on eye plates or parts designed specifically for welding.

What is the strongest eye bolt?

The strongest type is a forged shoulder eye bolt made from high-strength alloy steel, stainless steel, or titanium. One-piece forged construction provides the highest load capacity and reliability.

Can HDC customize eye bolts according to drawings or samples?

Yes. HDC specializes in custom forged eye bolts and can produce exactly according to your drawings, 3D models, or physical samples. We support design review, material selection, and CNC machining for precise threads and dimensions.

Does HDC have an MOQ for a custom forged eye bolt?

MOQ depends on the size, material, and complexity. For most custom forged eye bolts, the MOQ is small to medium batch, and we’ll confirm the best quantity after reviewing your design.