جدول المحتويات

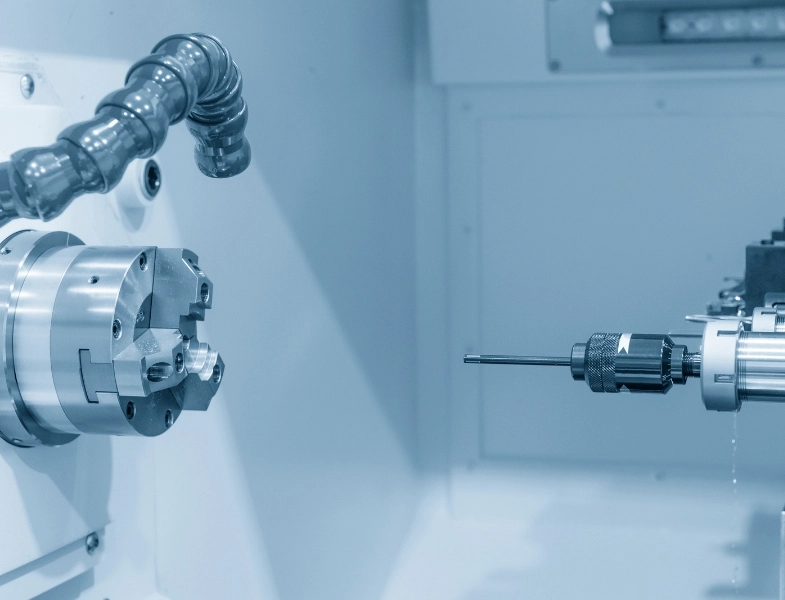

ما هو G Code؟ هل هو جانب أو مكون مهم في تصنيع المواد أو المكونات؟ نظرًا لأنه "كود"، فهل له علاقة بالكمبيوتر؟ في هذه المدونة، سنقدم لك جميع المعلومات المهمة حول G Code. بدءًا من ماهيته، وأين يتم استخدامه، وكيف يمكنك الاستفادة منه، لقد جمعنا لك كل شيء!

رموز G و رموز M يجب أن يعملوا معًا لضمان عمليات CNC سلسة. بينما تحدد أكواد G كيفية تحرك الأداة، تدير أكواد M وظائف الآلة الأساسية. يساعد فهم الفرق المشغلين على برمجة الآلات بدقة، وتحسين الدقة والكفاءة في التصنيع.

فهم رموز G ورموز M

مصدر: أندرسون أمريكا

مصدر: أندرسون أمريكا

رموز G مقابل رموز M: ما الفرق بينهما؟

بخلاف الحرف الأول، تختلف هذه الحروف أيضًا من حيث الاستخدام العام والوظيفة. إليك جدول يمكنك الاطلاع عليه والاطلاع عليه لزيادة معرفتك فيما يتعلق بالاختلاف العام بينهما:| وجه | رموز G | رموز M |

| غاية | يتحكم في حركة الأداة وتحديد موقعها | يدير عمليات ووظائف الآلة |

| ركز | مسارات القطع والسرعة والاتجاه | إجراءات مثل سائل التبريد والمغزل والتوقفات |

| نوع الأمر | تعليمات مبنية على الهندسة | الأوامر المتعلقة بتشغيل الآلة |

| أمثلة شائعة | G01 (حركة خطية)، G02 (حركة دائرية) | M03 (المحور قيد التشغيل)، M08 (سائل التبريد قيد التشغيل) |

| التأثير على الآلة | يؤثر بشكل مباشر على مسار الأداة وعملية القطع | يتحكم في سلوك الماكينة ووظائف الدعم |

| تنفيذ | يتم تشغيله بشكل مستمر طوال البرنامج | يتم تنفيذه مرة واحدة لكل دورة أمر |

ما هو رمز G؟ معناه، وظيفته، استخداماته، أنواعه، والمزيد!

G Code، اختصارًا لـ engineering code، هي لغة برمجة تستخدم في آلات CNC (التحكم العددي بالحاسوب). وهي تخبر هذه الآلات بكيفية الحركة، والسرعة التي يجب أن تتحرك بها، وأين يجب أن يكون مسارها. يتحكم كل أمر من أوامر G Code في إجراء معين، مما يضمن التشغيل الدقيق والآلي. الغرض من G Code وتطبيقاته مصدر: 3ERP

مصدر: 3ERP

يقوم G Code بترجمة مواصفات التصميم إلى تعليمات يمكن قراءتها بواسطة الآلة. فهو يتحكم في حركة الأداة، ويحدد المواضع والمنحنيات والقطع المستقيمة.

يعد G Code ضروريًا لدقة وكفاءة آلات CNC في قطاعات مثل التصنيع والسيارات والفضاء الجوي. بدون G Codes، لن يكون أتمتة الآلات والمشاريع ممكنًا.أنواع رموز G

لأن لها أنواع واستخدامات مختلفة، هناك أنواع مختلفة و أنواع أكواد gغرضها هو المساعدة في تصنيف الأوامر المحددة لتسهيل التعرف عليها بشكل أكثر كفاءة.- رموز الحركة (G00-G03):التحكم في الحركات الخطية والدائرية.

- رموز وضع الأدوات (G17-G19):ضبط مستوى القطع.

- رموز معدل التغذية والسرعة (G20-G21):ضبط الوحدات وسرعة القطع.

- رموز الدورة المعلبة (G81-G89):أتمتة تسلسلات الحفر والقطع المتكررة.

- تعويضات العمل (G54-G59):تحديد مواضع قطعة العمل للتصنيع الدقيق.

أهمية G Code

لماذا تعتقد أن G code مهم؟ يضمن G Code الدقة والقدرة على التكرار في تصنيع الآلات ذات التحكم الرقمي بالكمبيوتر. فهو يسمح للمشغلين بأتمتة المهام المعقدة، مما يقلل من الأخطاء ويزيد من سرعة الإنتاج. يساعد إتقان G Code الشركات المصنعة على تحسين الجودة والكفاءة والفعالية من حيث التكلفة في الإنتاج.أوامر G Code

تُعرف هذه الأوامر أيضًا باسم أنواع G Code، وهي تتيح لآلات CNC التحرك في اتجاه محدد للغاية في المستوى الإحداثي الديكارتي (النظام). علاوة على ذلك، فإن هذه الخطوط مسؤولة عن تحديد المواقع والتشغيل والسرعة والإزاحات التي تقوم بها الآلة. لذلك، لمساعدتك في رحلة التصنيع باستخدام آلات CNC، إليك قائمة G Code التي ستحتاجها دائمًا!| كود G | وظيفة | وصف |

| جي00 | تحديد المواقع السريع | يحرك الأداة بسرعة إلى الوضع المحدد دون قطع. |

| ج01 | الاستيفاء الخطي | يحرك الأداة في خط مستقيم بسرعة محددة. |

| جي02 | الاستيفاء الدائري (باتجاه عقارب الساعة) | يقطع قوسًا أو دائرة في اتجاه عقارب الساعة. |

| ج03 | الاستيفاء الدائري (عكس اتجاه عقارب الساعة) | يقطع قوسًا أو دائرة في اتجاه عكس عقارب الساعة. |

| ج04 | يسكن | يقوم بإيقاف الحركة مؤقتًا لفترة زمنية محددة قبل الاستمرار. |

| جي17 | اختيار المستوى XY | يضبط مستوى التصنيع على المحور XY. |

| مجموعة 18 | اختيار الطائرة XZ | يضبط مستوى التشغيل على المحور XZ. |

| مجموعة 19 | اختيار طائرة YZ | يضبط مستوى التصنيع على المحور YZ. |

| مجموعة العشرين | اختيار وحدة البوصة | يقوم بتبديل وحدات القياس إلى البوصات. |

| مجموعة الـ21 | اختيار الوحدة المترية | يقوم بتحويل وحدات القياس إلى ملليمترات. |

| جي28 | العودة إلى الصفحة الرئيسية للجهاز | يقوم بإرجاع الأداة إلى موضعها الأصلي. |

| جي40 | تعويض القاطع متوقف | يلغي تعويض قطر الأداة. |

| جي41 | تعويض القاطع الأيسر | ضبط مسار الأداة للقطع على يسار الخط المبرمج. |

| جي42 | حق تعويض القاطع | ضبط مسار الأداة للقطع على يمين الخط المبرمج. |

| جي54-جي59 | نظام إحداثيات العمل (WCS) | يقوم بتعريف نقاط صفر مختلفة لإعدادات التصنيع. |

| جي90 | التموضع المطلق | تحريك الأداة استنادًا إلى نقطة مرجعية ثابتة. |

| جي91 | التموضع التدريجي | تحريك الأداة بناءً على موضعها الحالي. |

| جي98 | العودة إلى المستوى الأولي | يقوم بإرجاع الأداة إلى مستوى البداية بعد دورة معلبة. |

| جي99 | عودة مستوى R | إرجاع الأداة إلى مستوى محدد مسبقًا بدلاً من نقطة البداية. |

فهم ملفات G Code

ملفات G Code عبارة عن ملفات نصية عادية تحتوي على تعليمات لآلات CNC. وهي تحدد حركات الأدوات ومسارات القطع وسرعات المغزل ومعدلات التغذية. عادةً ما تحتوي هذه الملفات على امتدادات مثل- .gcode

- .ن سي

- .مقبض

- .سي إن سي

اختر HDC لمشروع التصنيع باستخدام الحاسب الآلي المخصص الخاص بك

نحن في HDC نعمل مع آلاف الشركات المصنعة والموردين الذين يقدمون عمليات تصنيع CNC المتنوعة. تشمل تخصصاتنا الفضاء الجوي, السيارات, تصنيع, طبي، ل مواصلات وصناعات البناء. يمكنك الاعتماد علينا إذا كنت بحاجة إلى مساعدة في التصنيع الدقيق والتصنيع الضخم وحتى استخدام أي منتج لذلك أيضًا! لا تتردد في الاتصال بنا أو مراسلتنا عبر البريد الإلكتروني إذا كنت بحاجة إلى مساعدة في مشاريع التصنيع باستخدام الحاسب الآلي! احصل على عرض أسعار مجاني لأي شيء يحتاجه مشروعك!

جدول المحتويات

اكتشف المزيد مع منشورات مدونتنا.

المشاركات الاخيرة

اكتشف المزيد عن منتجاتنا.

المنتجات ذات الصلة

اقتباس فوري!