Fabricación integral de piezas metálicas personalizadas en China

Simplifique su cadena de suministro con procesos de fabricación integrados, que incluyen mecanizado CNC, fundición, forja y más.

🛡️ Todo el contenido cargado se mantiene seguro y confidencial.

Capacidades básicas

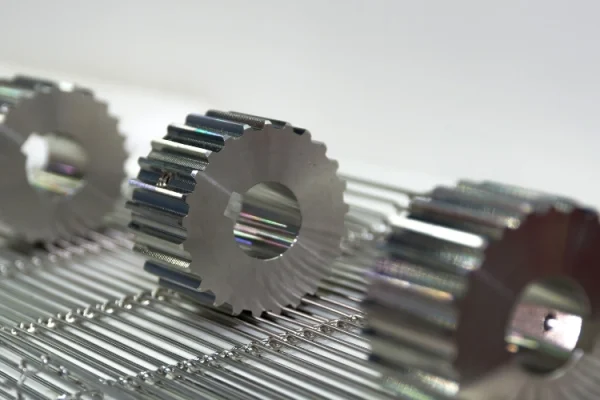

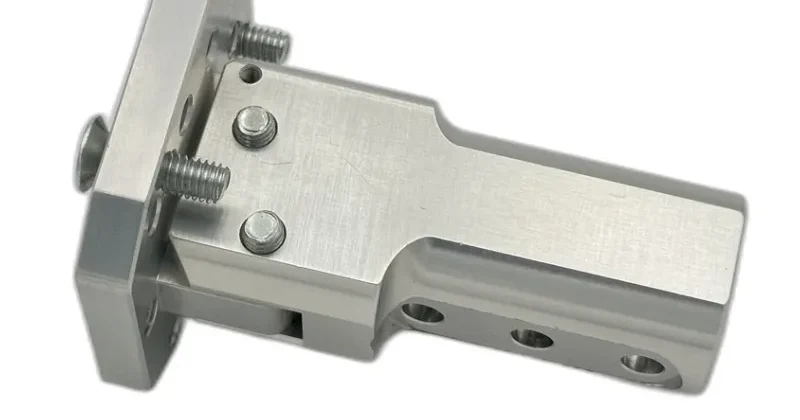

Mecanizado CNC

- Equipado con 3 ejes, 4 ejes, y 5 ejes Centros de mecanizado CNC.

- Tolerancia estricta hasta ±0,005 milímetros.

- Acabado CNC de dimensiones críticas para piezas fundidas y forjadas.

- Control de dimensión crítica.

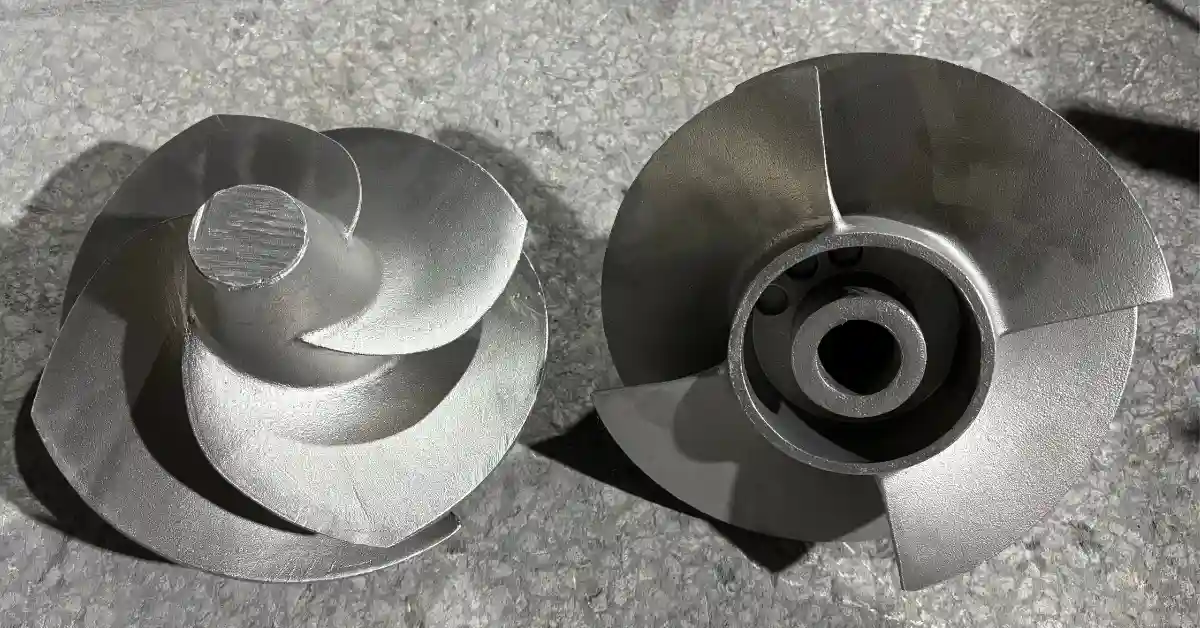

Fundición

- Fundición de precisión con acero inoxidable, aleación de níquel, y más.

- 50 kilos máxima fundición única.

- Tolerancia estricta con acabado CNC.

- Solución personalizada en procesos de fundición, configuración del material, y tratamiento térmico.

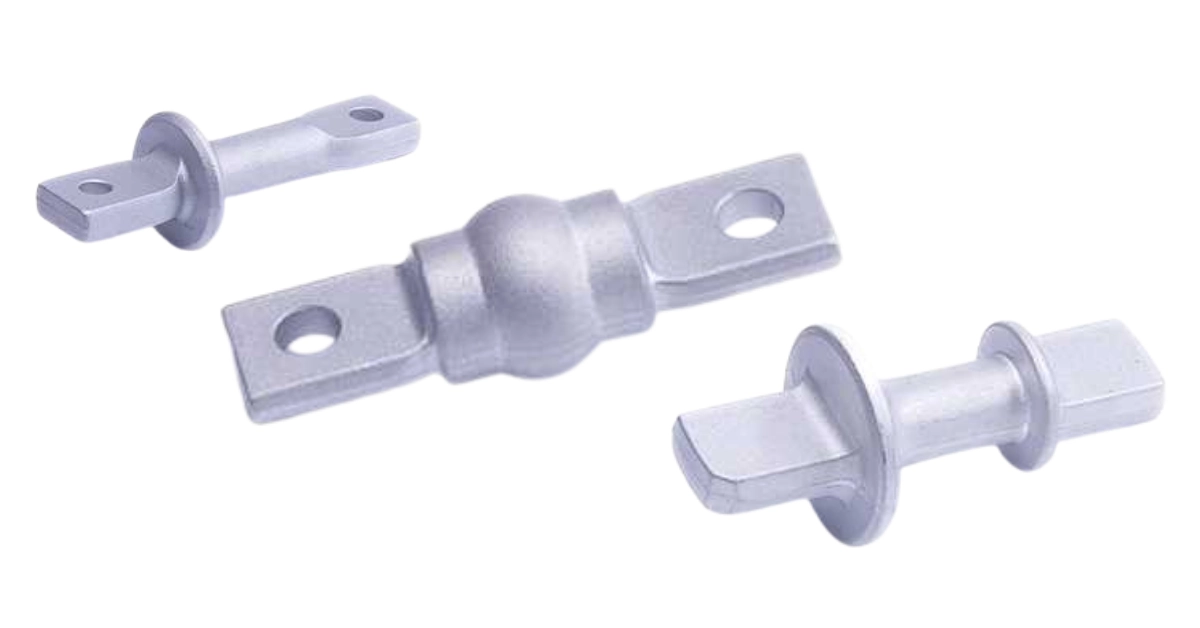

Forjar

- Forja con aleación de aluminio, acero carbono, y acero inoxidable.

- 30 kilos forjado único máximo.

- 160T ~ 4000T Prensas de forja y prensas de tornillo.

- Están disponibles forjados en frío y en caliente.

Servicio global

Atendemos a más de 1000 clientes de más de 50 países.

Certificación ISO e IATF

Contamos con la certificación ISO9001:2005.

Más de 50 materiales certificados

Podemos personalizar sus piezas metálicas con más de 50 tipos de materiales diferentes.

El tiempo de entrega

Las piezas le serán entregadas según lo prometido, de 1 semana a 30 días.

Para obtener más información, visite nuestra Política de servicio página.

¿Por qué elegir HDC Manufacturing?

Más que un fabricante: su socio en ingeniería y cadena de suministro

Un proyecto real puede ser complejo y requerir la combinación de múltiples procesos de fabricación para fabricar los componentes deseados. Para los fabricantes de marcas, gestionar múltiples proveedores en diferentes procesos puede volverse rápidamente complejo y arriesgado.

Comenzando como un taller CNC, hemos seguido enriqueciendo nuestras capacidades en fabricación y desarrollando nuestra cadena de suministro, con el objetivo de brindar una solución integral para nuestros clientes.

Con nuestra experiencia en mecanizado CNC, reunimos los mejores recursos de fabricación de China en fundición y forja bajo un sistema de calidad único y confiable. Desde la ingeniería y el abastecimiento hasta el control de calidad y la logística, nos encargamos de la complejidad para que usted pueda centrarse en su producto, no en sus proveedores.

Eleve su marca con soluciones personalizadas

En HDC Manufacturing, vamos más allá de la fabricación. Trabajamos como un socio práctico y directo para ayudarle a llevar sus ideas de producto a producción. Desde los conceptos iniciales hasta los componentes terminados, ofrecemos soporte en piezas metálicas personalizadas y mecanizado de precisión tanto para marcas en crecimiento como consolidadas.

Con mecanizado CNC, fundición y forja integrados, lo ayudamos a moverse más rápido, reducir la complejidad de la cadena de suministro y lograr una calidad constante, para que pueda concentrarse en construir su marca y no en administrar proveedores.

Proceso de pedido

Consulta inicial

Comparta los requisitos de su proyecto con nuestro equipo. Revisaremos su solicitud y le brindaremos información práctica de ingeniería para ayudarle a comenzar.

Presentación de diseño

Envíenos sus archivos de diseño o trabaje con nuestros ingenieros para perfeccionar el diseño para lograr fabricación y rentabilidad.

Revisión de cotizaciones y diseños

Recibirá una cotización clara y detallada junto con una revisión final de todas las especificaciones antes de continuar.

Desarrollo de prototipos

Cuando es necesario, producimos prototipos para validar el diseño, el ajuste y el rendimiento antes de la producción en masa.

Producción y control de calidad

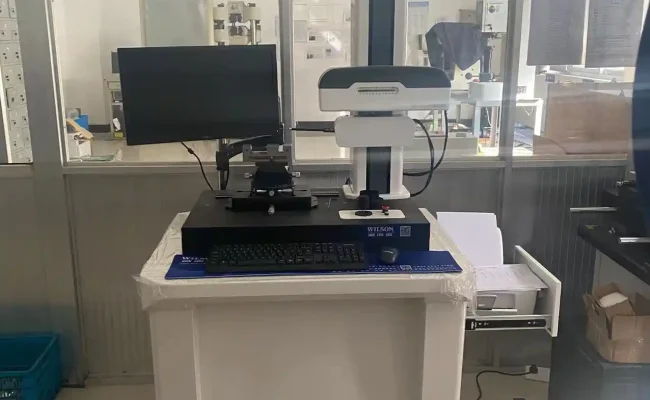

Una vez aprobada, comienza la producción a gran escala, respaldada por inspecciones durante el proceso y un estricto control de calidad en cada etapa.

Envío y entrega

Elige tu método de envío preferido. Organizamos envíos a todo el mundo con plazos de entrega fiables.

Acceda a nuestros recursos para conocer más sobre las capacidades de HDC.

Materiales metálicos con los que trabajamos

HDC Manufacturing trabaja con una amplia gama de materiales metálicos para satisfacer diferentes requisitos de resistencia, peso y rendimiento.

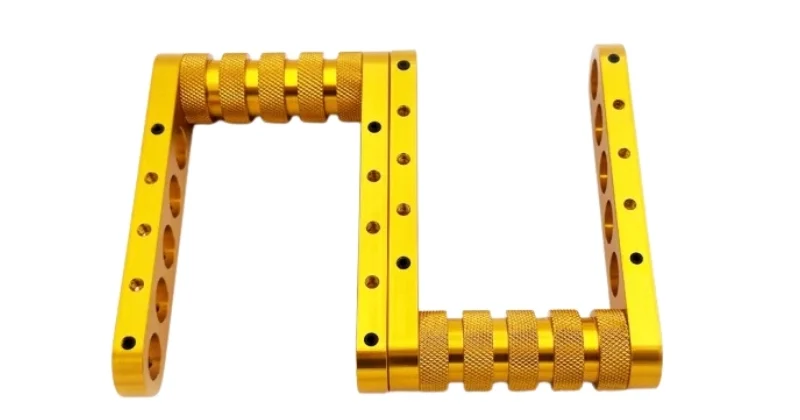

Opciones integrales de tratamiento de superficies

Con un acabado de superficie integrado en casa y una cadena de suministro de postratamiento confiable, HDC Manufacturing ofrece una gama completa de tratamientos de superficie para mejorar la apariencia, la durabilidad y el rendimiento funcional de las piezas de metal personalizadas.

| 🔷 Chorro de arena | 🔷 Granallado |

| 🔷 Anodizado tipo Ⅱ | 🔷 Anodizado tipo III |

| 🔷 Recubrimiento en polvo | 🔷 Pintura |

| 🔷 Recubrimiento de zinc | 🔷 Cromado |

| Grabado láser | Óxido negro |

Tratamiento térmico para piezas metálicas

El tratamiento térmico juega un papel fundamental para lograr la resistencia, dureza y durabilidad requeridas de las piezas metálicas.

Con procesos de tratamiento térmico controlados y una cadena de suministro de postratamiento confiable, respaldamos una gama completa de opciones de tratamiento térmico para optimizar las propiedades del material para diferentes aplicaciones.

| 🔷 Enfriamiento | 🔷Templado |

| 🔷 Recocido | 🔷Normalizando |

| Tratamiento de solución |

Control de calidad

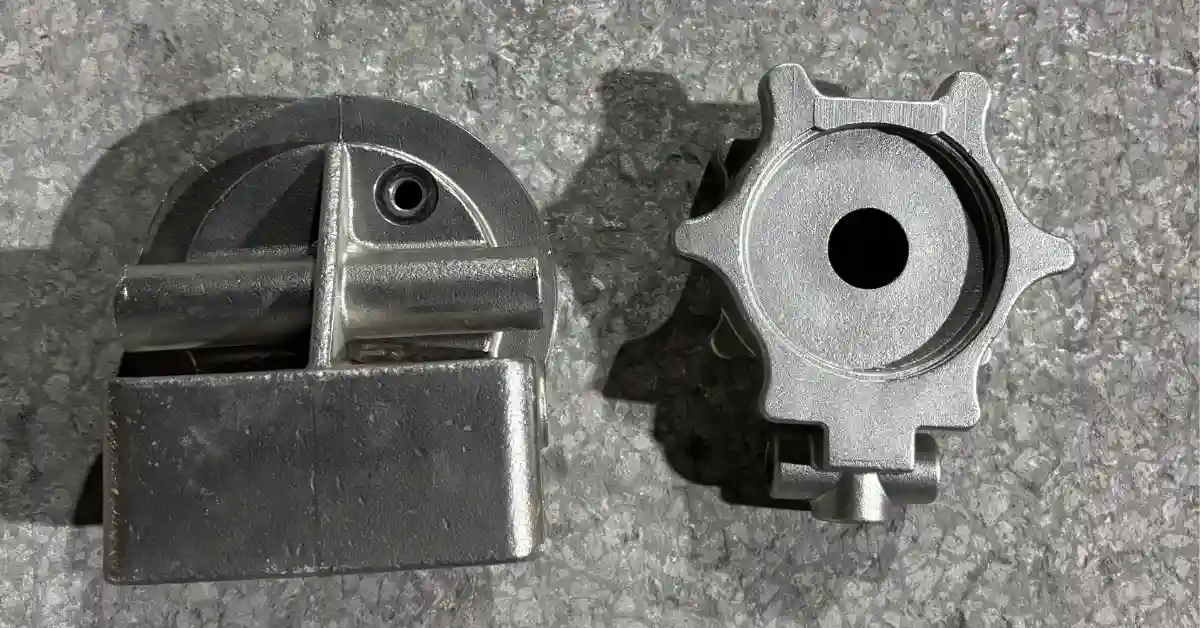

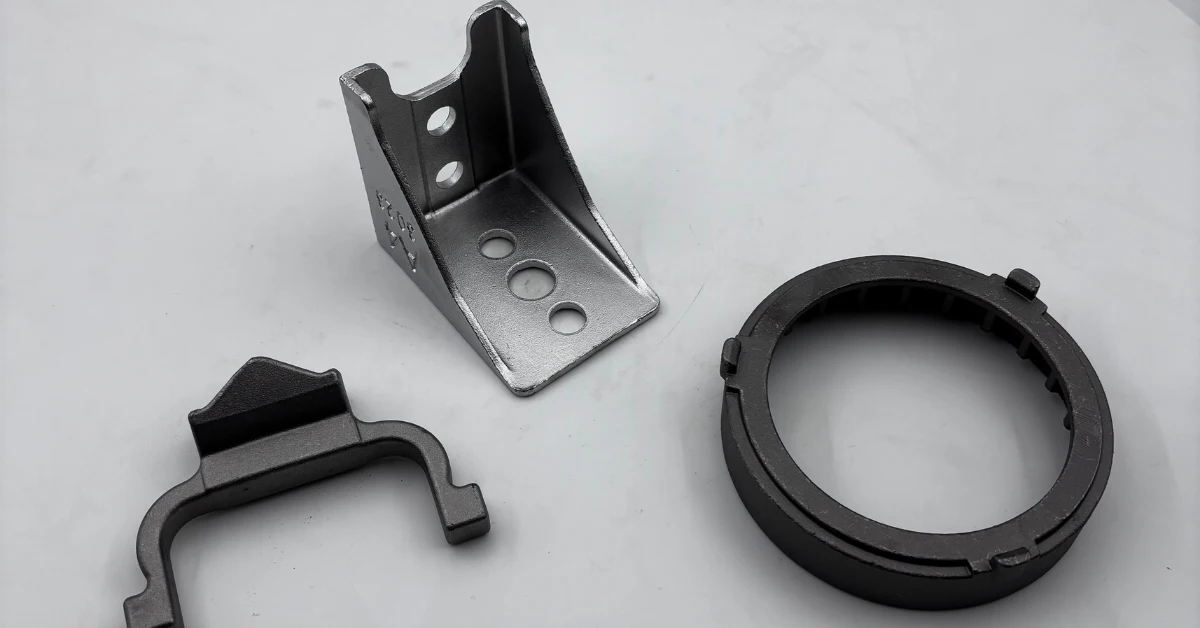

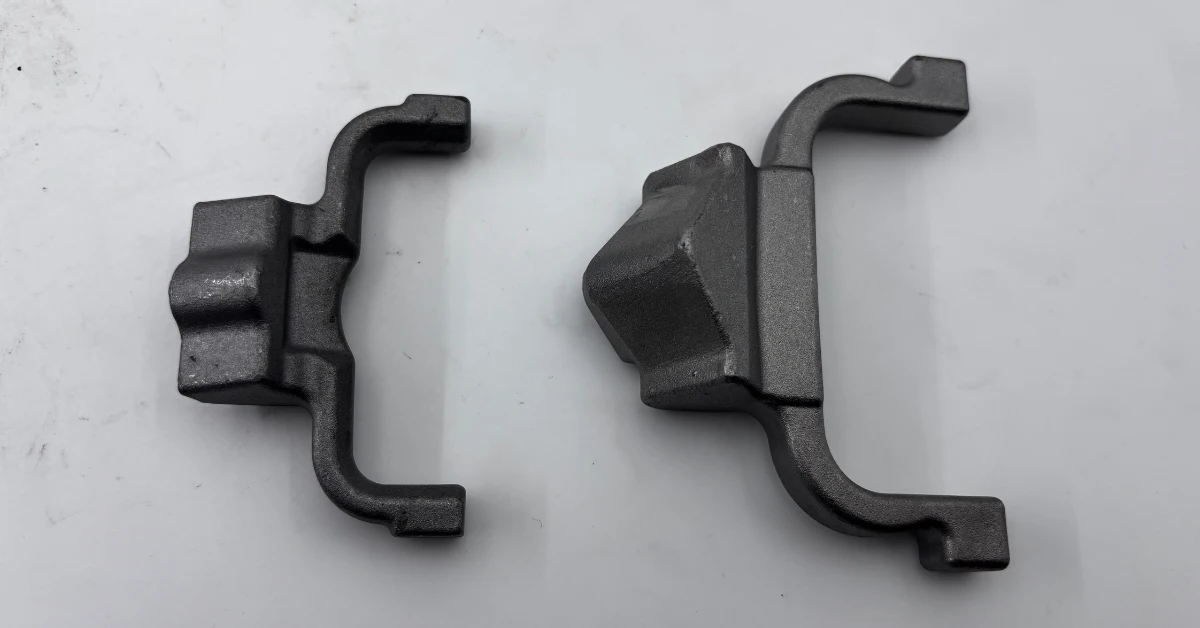

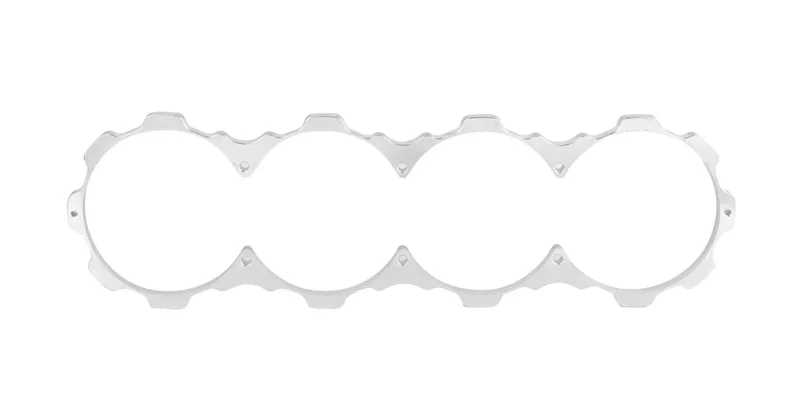

Productos fabricados a medida

Componentes forjados, fundidos y mecanizados por CNC para múltiples industrias

Componentes automotrices forjados

Componentes forjados para motocicletas

Accesorios para volante y dirección

Componentes estructurales y de herramientas forjados

Herramientas, soportes y accesorios

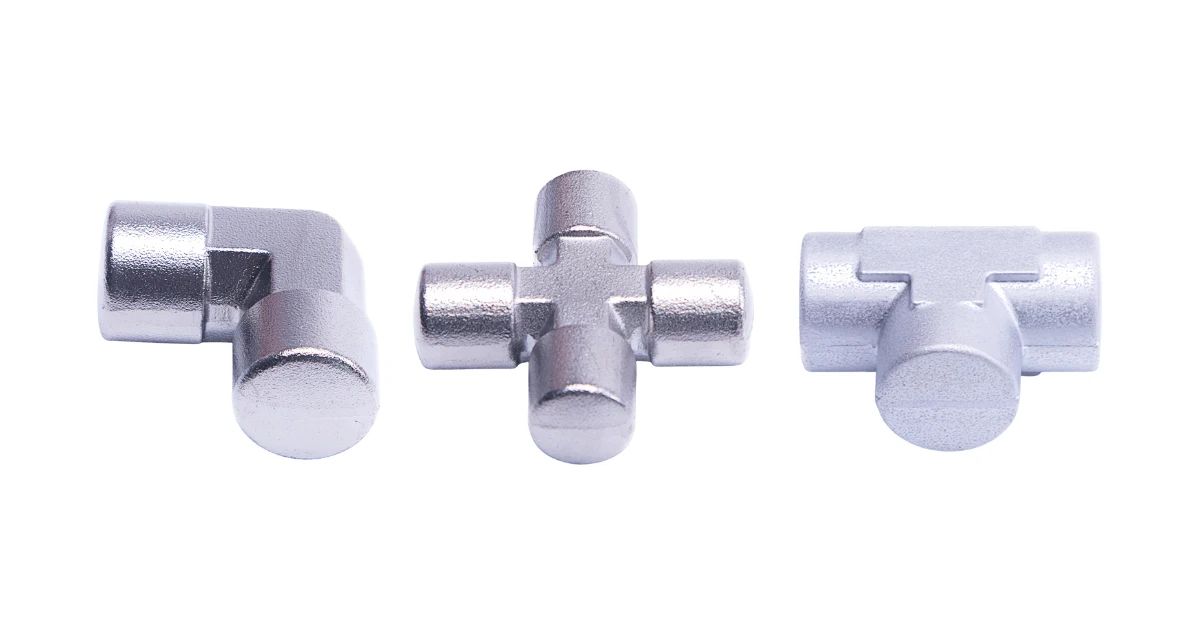

Componentes de fundición industrial

Cuerpo de la bomba, válvula, caja de engranajes

Piezas de fundición para vehículos

Piezas para coches, motocicletas, bicicletas y bicicletas eléctricas

Herrajes y fundiciones estructurales

Conectores, soportes y herrajes personalizados

Piezas de karts CNC

Piezas de motocicleta CNC

Piezas automotrices CNC

Lo que dicen nuestros clientes

Preguntas frecuentes

Todo lo que necesita saber antes de trabajar con HDC Manufacturing.

¿Cómo solicito una cotización?

Para solicitar un presupuesto, simplemente comparta los detalles de su proyecto con nosotros, incluyendo planos, requisitos de materiales y cualquier especificación especial. Nuestro equipo de ingeniería revisará su información y le proporcionará un presupuesto claro y detallado lo antes posible.

¿Cuál es el plazo de entrega típico para pedidos personalizados?

Los plazos de entrega varían según la complejidad de las piezas, la cantidad y los procesos de fabricación. En la mayoría de los proyectos personalizados, la producción puede completarse en pocas semanas. Los plazos de entrega estimados se confirman durante la fase de cotización.

¿Cuáles son las opciones de envío disponibles?

Ofrecemos opciones de envío flexibles, incluyendo transporte aéreo, marítimo y envío exprés. Realizamos envíos a todo el mundo y podemos acordar condiciones FOB según sus necesidades.

¿Cómo garantiza HDC Manufacturing la calidad del producto?

La calidad se controla en cada etapa de la producción. Desde la inspección de la materia prima hasta los controles durante el proceso y la inspección final, nuestro sistema de calidad cuenta con el respaldo de la certificación ISO para garantizar la consistencia y la fiabilidad de cada pedido.

¿Existe una cantidad mínima de pedido (MOQ)?

El pedido mínimo depende del tipo de producto, el material y el proceso de fabricación. Ofrecemos volúmenes de producción flexibles y le invitamos a contactarnos para hablar sobre la solución más adecuada para su proyecto.

¿Puede HDC Manufacturing ayudar con el diseño o la creación de prototipos?

Sí. Brindamos soporte de ingeniería y servicios de creación de prototipos para ayudar a optimizar su diseño en términos de capacidad de fabricación, rendimiento y costo antes de la producción en masa.

¿Qué métodos de pago aceptan?

Aceptamos métodos de pago seguros, como transferencias bancarias, PayPal y otras opciones comunes. Las condiciones de pago se confirman durante el proceso de pedido para garantizar la claridad y la transparencia.

¿Ofrecen apoyo a quienes importan por primera vez?

Sí. Trabajamos regularmente con importadores primerizos y les brindamos orientación sobre Incoterms, despacho de aduanas y opciones de envío para garantizar un proceso de importación sin inconvenientes.

¿Cómo puedo comunicarme con HDC Manufacturing para obtener más información?

Puede contactarnos a través de nuestra página de contacto, correo electrónico o teléfono. Nuestro equipo está listo para hablar sobre su proyecto y responder cualquier pregunta que tenga.

Démosle vida a tu diseño

Sube tus dibujos técnicos (STEP, IGES o PDF) para obtener una opinión profesional en DFM (Diseño para fabricación) y una cotización competitiva dentro de las 24 horas.

* Revisión de ingeniería disponible. Se puede firmar un acuerdo de confidencialidad a solicitud.