Fabricant professionnel de pièces aérospatiales

HDC respecte les normes strictes de l'industrie aérospatiale pour l'usinage de pièces destinées à ce secteur. Grâce à des technologies de traitement avancées, telles que l'usinage 5 axes et l'impression 3D, HDC fabrique des pièces aérospatiales alliant précision et qualité.

De l'aluminium au titane en passant par les alliages de nickel résistants à la chaleur, HDC fabrique des composants dans des dizaines de matériaux pour les avions, les drones et les satellites. Garantissant la qualité et des délais d'exécution rapides, HDC personnalise des prototypes de pièces aéronautiques en une semaine par usinage CNC.

Délai d'exécution rapide

Prototypage rapide

Rentable

Haute précision

Types de pièces aérospatiales

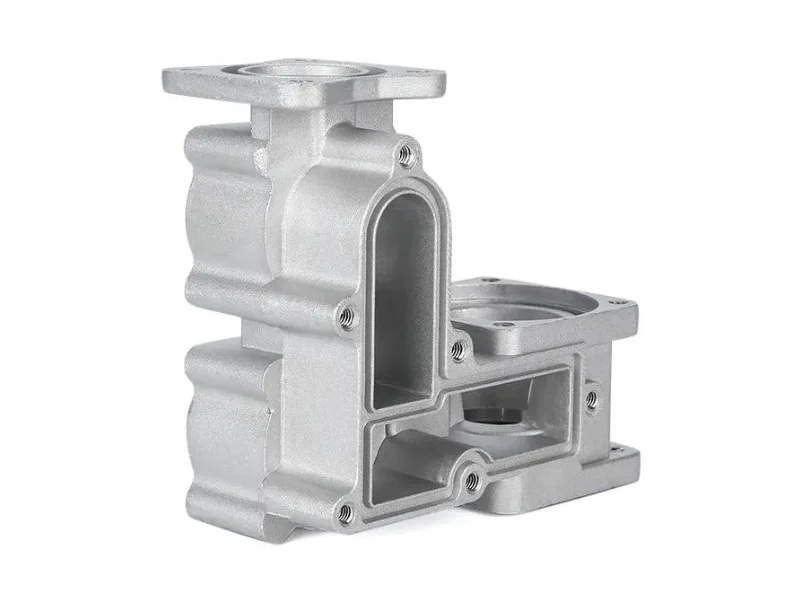

Cadre et boîtier

HDC utilise des matériaux légers comme l'aluminium pour produire des cadres et des boîtiers de composants électroniques utilisés dans l'industrie aérospatiale. Grâce à la technologie CNC, HDC peut facilement usiner des structures à parois fines et percer des trous de montage avec une grande précision, offrant ainsi un environnement sûr et stable pour les composants électroniques fragiles.

Connecteur et matériel

HDC personnalise des connecteurs électriques en cuivre et des boulons et écrous en alliage de titane haute résistance selon les spécifications de ses clients, ce qui améliore considérablement la stabilité des câbles de connexion et renforce la durabilité et la sécurité des interfaces de composants critiques. Ces deux solutions sont conçues pour les environnements exigeants.

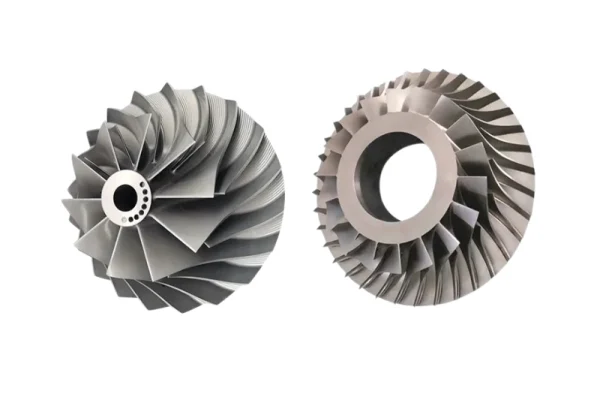

Composants du système moteur

Usinage HDC d'alliages de nickel réfractaires (Inconel, Hastelloy) pour la production de composants moteurs critiques tels que des turbines et des aubes de compresseur. Nous utilisons le fraisage 5 axes pour fabriquer ces pièces à géométrie complexe et obtenons une précision élevée jusqu'à ± 0,005 mm afin de garantir le bon fonctionnement du système d'alimentation.

Pièces aérospatiales par procédé d'usinage

HDC intègre plusieurs processus d'usinage pour fabriquer des pièces capables de résister aux environnements difficiles dans l'espace.

Tournage CNC

Convient à l'usinage de produits de forme cylindrique, tels que des connecteurs et des tubes.

Fraisage CNC

HDC utilise de l'aluminium léger 7075 pour usiner des boîtiers et des boîtiers pour drones et avions.

Usinage 5 axes

Grâce au centre d'usinage 5 axes avancé, HDC fabrique les pièces les plus précises.

impression en 3D

HDC utilise l’impression 3D pour imprimer des pièces en métal et en plastique avec des structures internes complexes.

Forgeage

Nous forgeons de l'aluminium 7075 de qualité aérospatiale pour fabriquer des pièces critiques qui nécessitent une résistance extrême.

Fonderie

Grâce au moulage par cire perdue, nous produisons en série des pièces aérospatiales dotées de structures internes complexes.

Découpe au laser

Un procédé d’usinage rentable, souvent utilisé pour fabriquer des panneaux ou couper des matières premières.

Matériaux pour pièces aérospatiales

Les matériaux sont à la base de pièces aérospatiales de haute qualité. HDC fournit des matériaux certifiés pour diverses applications aérospatiales.

Alliage d'aluminium

Plus de 10 alliages d'aluminium disponibles chez HDC, notamment 7075, 6061, 6063 et 5083, etc.

Alliage de titane

Nous sommes expérimentés dans l'usinage d'alliages de titane à haute résistance, tels que les grades 5 et 7.

Acier inoxydable

HDC fournit des nuances d'acier inoxydable certifiées pour les pièces aérospatiales : 304, 303, 316, etc.

Alliage à base de nickel

L'Inconel et l'Hastelloy sont conçus pour les pièces aérospatiales qui nécessitent résistance et résistance à la chaleur.

Personnaliser les pièces aérospatiales avec la diversité

Pour personnaliser une pièce aéronautique pour votre projet, HDC est un partenaire idéal. Grâce à nos nombreuses options de personnalisation, nos clients peuvent facilement acheter des pièces parfaitement adaptées à leurs besoins.

- Taille de la pièce : HDC fabrique des pièces dans une large gamme de tailles, de 1000 mm à 1 mm.

- Matériaux: Plus de 50 matériaux sont disponibles pour les pièces aérospatiales, notamment l'aluminium et le titane.

- Finitions : Anodisation, chromage, peinture et thermolaquage : HDC propose plus de 10 types de finitions.

- Processus d'usinage : Nous combinons différentes méthodes de processus pour fabriquer des pièces aérospatiales, telles que l'usinage CNC, l'usinage 5 axes, le forgeage et le moulage.

Caractéristiques des pièces aérospatiales HDC

- Combiner plusieurs processus : HDC combine l'usinage CNC avec le forgeage ou le moulage, ce qui confère à nos pièces aérospatiales précision, résistance et détails internes en même temps, parfaitement adaptées aux applications aérospatiales.

- Poids léger: Nous utilisons des matériaux légers et intégrons une conception légère complète, nos pièces sont spécialement conçues pour le secteur aérospatial afin de réduire efficacement le poids.

- Excellente résistance : Nous utilisons du titane et des superalliages pour fabriquer des pièces critiques, qui peuvent satisfaire aux exigences de haute résistance et de résistance à la chaleur extrême dans l'aérospatiale.

Besoin de pièces répondant aux normes aéronautiques geade ?

Oui, nous proposons un service de prototypage. Pour plus d'informations, veuillez contacter notre équipe commerciale.

Pour les pièces simples, généralement sous une semaine. Nous devons les estimer à partir de plans ou d'échantillons.

Absolument, la remise spécifique est déterminée en fonction de la quantité.

Oui, tous les clients sont invités à visiter notre usine, veuillez nous contacter à l'avance pour obtenir un rendez-vous.

Oui, nous offrons une certification sur demande.

Oui, nous sommes une usine certifiée IAIF et ISO, avec plus de 3 000 mètres carrés d'atelier et 80 employés.