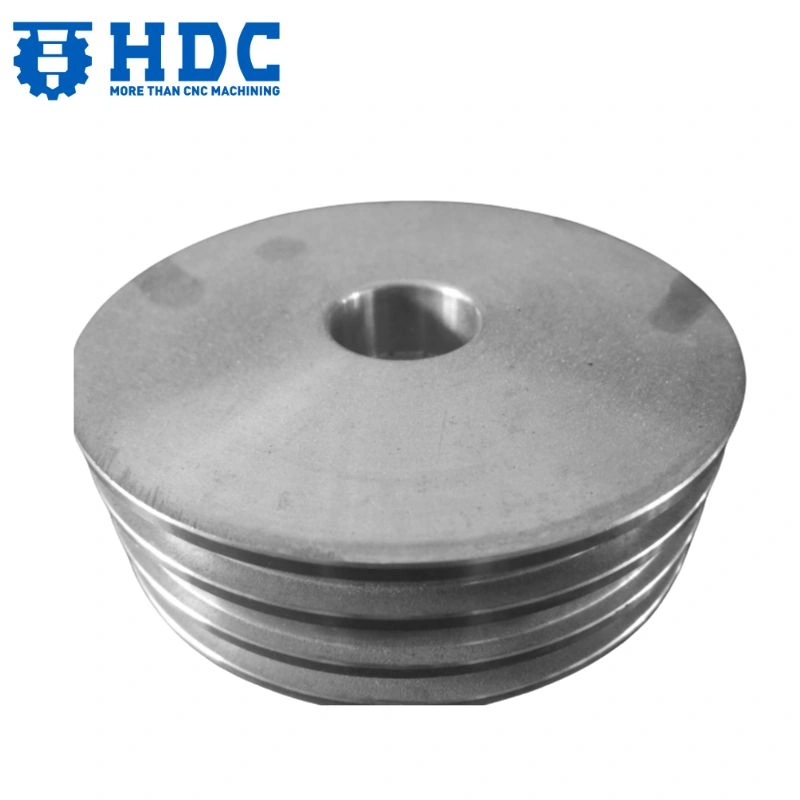

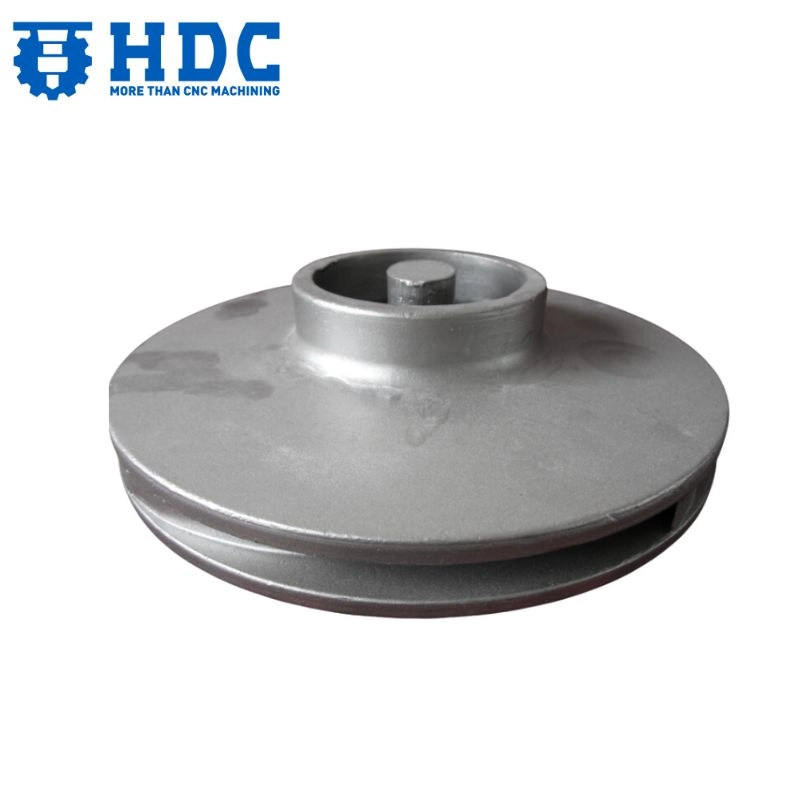

Pièces de pivot d'attelage pour tracteur en acier au carbone/aluminium moulées à la cire perdue

Détails du produit personnalisé

| Numéro de modèle. | HDCIKP001 |

| Style | Pivot d'essieu moulé par investissement |

| Matériel | Aluminium, alliage d'aluminium, acier, alliage d'acier, superalliage, laiton |

| Type de finition | Brut, poli, anodisé, revêtu par électrophorèse, revêtu de poudre, galvanisé, chromé, oxydé noir |

| Taille disponible | / |

| MOQ | 50 pièces |

| Logo personnalisé | Disponible |

| Origine | Chine |

| Emballage et livraison | |

| Option d'expédition | Courrier, air, mer, chemin de fer express, EXW, FOB, CIF, DDU, DDP |

| La date de livraison | 25-30 jours |

| Forfait Transport | Personnalisé, Carton, Palette |

Anchor the steering precision and structural integrity of heavy-duty agricultural machinery with this investment-cast kingpin. Precision-engineered for tractors, harvesters, and off-road equipment demanding uncompromising load-bearing capacity and environmental resistance, this component forms the pivotal foundation between chassis and wheel end—delivered with the geometric accuracy and metallurgical density only investment casting can provide.

Dual-Material High-Strength Selection: Available in high-strength carbon steel for maximum load capacity and impact resistance, or lightweight aluminum for mass-sensitive agricultural applications—each precision-selected to match specific vehicle weights, steering loads, and duty cycle requirements.

Investment-Cast Geometric Precision: Precision investment casting enables the formation of complex taper profiles, integrated thrust faces, and threaded or cross-hole retention features in a single, void-free structure—maintaining exacting angular accuracy and concentricity critical for zero-free-play steering articulation.

Dense, Homogeneous Material Structure: Near-net-shape casting fidelity eliminates internal porosity and stress risers common to forged or machined bar stock alternatives, delivering consistent mechanical properties throughout the kingpin body and verified fatigue life under continuous oscillatory steering loads.

Surface-Hardened Wear Resistance: Optional case hardening, induction hardening, or nitriding treatments provide deep, metallurgically bonded wear surfaces at critical thrust and bearing journal interfaces—significantly extending service life in continuously contaminated agricultural environments.

Corrosion-Protected Longevity: Available in zinc plating, manganese phosphate, or heavy-duty epoxy coatings—providing lasting barrier protection against fertilizer exposure, field moisture, and seasonal equipment storage conditions.

Configuration entièrement personnalisable: Manufactured to customer-specific overall lengths, journal diameters, taper angles, retention methods (cross-hole, threaded, or pinch-bolt), and greasing provisions—accommodating everything from high-volume OEM tractor production to one-off custom agricultural implement builds.

Direct OEM Replacement or Bespoke Engineering: Precision-cast to replicate original equipment geometry for seamless service replacement, or engineered from clean sheet to meet specialized steering geometry, load capacity, and packaging constraints for prototype and low-volume agricultural machinery.

Applications:

Heavy-Duty Tractor Steering Axles: Ideal for two-wheel-drive and mechanical front-wheel-drive (MFWD) applications requiring verified vertical load capacity and extended wear life under continuous steering articulation.

Agricultural Implement Chassis: Essential for hay balers, forage harvesters, and self-propelled sprayers operating in field conditions with continuous exposure to abrasive soils and moisture.

Trailer & Wagon Steering Systems: Suitable for heavy-duty grain carts, livestock trailers, and fertilizer tenders requiring positive steering control and maintenance-friendly kingpin replacement.

Custom & Restored Vintage Equipment: Accommodates heritage tractor restoration and one-off agricultural specialty vehicles requiring period-correct appearance with modern metallurgical integrity.

More than a steering pivot, this investment-cast kingpin is the mechanical conscience of your agricultural equipment’s front axle—preserving caster angle, absorbing impact loads, and ensuring every furrow-ending turn remains faithfully repeatable season after season. Whether you’re engineering next-generation autonomous tractors or restoring a legacy workhorse, it’s the component that proves field reliability begins with precision-cast, continuously grained articulation integrity.