Investment Casting Service for Pump Components

Custom pump housings, impellers, and casings — cast to your drawings.

We support pump OEMs and equipment manufacturers with precision investment casting and CNC finishing — not off-the-shelf pumps.

Who We Serve & What We Do

* This page covers manufacturing services for custom pump components only. Standard pump assemblies are not supplied.

Typical Pump Parts We Cast

You are the pro in design, we are the pro in manufacturing. Check out the components we can cast according to your drawing.

Pump Housing

Complex internal cavities cast as one piece, with CNC machining on sealing and mounting surfaces.

Pump Casing

Dimensionally stable castings suitable for pressure-bearing structures and precision-machined interfaces.

Turbine

Curved blade geometries cast to near-net shape, reducing extensive post-machining.

Diffuser

Intricate flow paths formed through investment casting, ensuring consistency between units.

Pump Cover

Thin-walled cast components with flatness and dimensional control for reliable assembly.

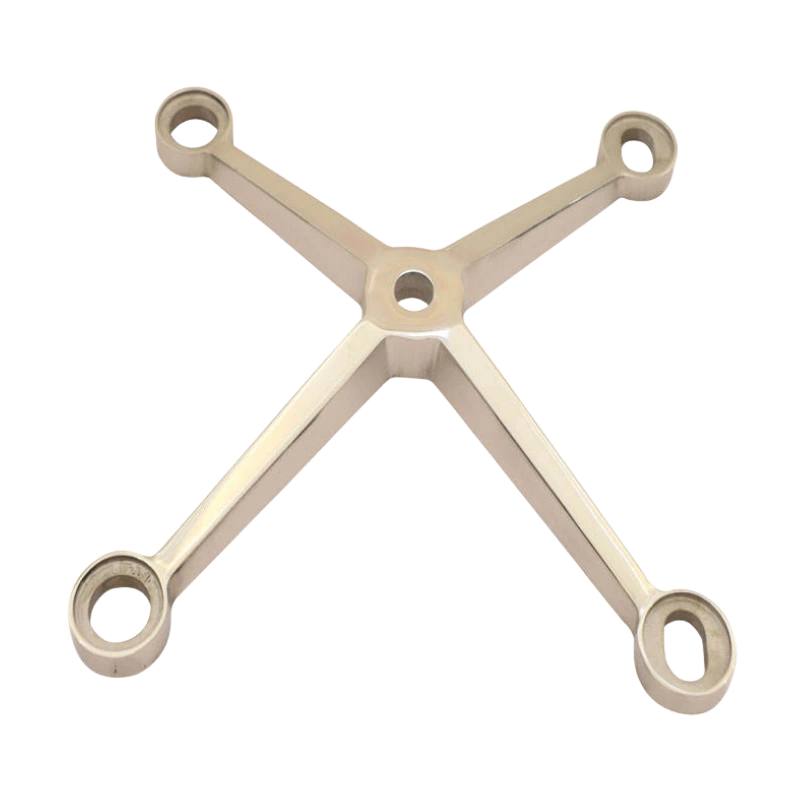

boîtier de roulement

Robust cast structures designed for load support, with CNC-finished bores and alignment features.

* All components are custom-manufactured based on customer drawings. Performance parameters such as flow rate or head are defined by the pump designer.

Why Investment Casting for Pump Components

What are the benefits of investment casting pump parts? Here is the answer:

Complex Internal Details

With investment casting, we can cast complex internal geometries as a single piece to improve structural continuity.

Smooth Flow Passages

Casting can achieve consistent internal surfaces that can’t be realized by 5-axis CNC, resulting in excellent fluid control performance.

Tight Dimensional Control

Through the precision-machined wax mold die and in-house CNC finish capabilities, we can achieve tight dimensional control.

Flexibilité matérielle

HDC cast a wide range of metals, including stainless steel, alloy steel, super alloy, etc. Custom material solution is also available.

Capacités de base HDC

From casting to CNC machining – We aim to be your one-stop supplier from raw casting to precision-machined pump components.

Moulage d'investissement

Following a proven investment casting process flow, we cast near-net shape pump parts with consistent quality, setting a solid foundation for the next manufacturing process.

Traitement thermique

With in-house heat-treatment equipment and comprehensive heat-treatment processes, we can apply approrate process to achieve desired physical properties.

Usinage CNC de précision

HDC supports 3-axis to 5-axis CNC machining for critical dimensions of cast pump components, such as seal faces and shaft bores. Offering parts that are ready for immediate assembly.

Pour un aperçu complet, veuillez consulter notre site web. Fonderie et Usinage CNC Pages de fonctionnalités.

Materials for Cast Pump Parts

Materials Commonly Used for Pump and Fluid-Handling Components

Carbon steel is suitable for general-purpose pump parts that need to balance strength and cost efficiency. We offer a wide range of carbon steel that are often applied in casting, including 1020 and 1045.

For pump systems that need to be exposed to high temperatures or harsh environments, we offer K18 as a material selection.

If your pump is designed to operate in extreme environments, such as high temperature, high pressure, and high corrosive conditions. We recommend nickel-based alloy to handle these situations, for instance, Inconel 625/718, Hastelloy C.

Capacités de fabrication

The table below shows a typical range of our manufacturing capabilities. Please reach us for details.

| Casting process | Investment casting (lost wax) |

| Common materials | 1045, 304, 316, K18, Inconel 718 |

| Maximum casting weight | 0.05kg – 100 kg |

| Maximum Size | 800mm x 600mm x 500mm |

| Minimal Wall thickness | 1.5mm – 2.5mm (Depends on part geometry and material) |

| Dimensional tolerance (as cast) | Typically CT6–CT7 |

| Rugosité de surface | Ra 3.2 μm – 6.3 μm |

| Traitement thermique | Normalizing, Annealing, Quenching, Tempering, Solution |

| Surface treatment | Shot Blasting, Pickling, Passivation, Electropolishing, Galvanizing, Painting |

| Usinage CNC | 4-axis & 5-axis CNC machining(±0.01mm) |

| Inspection | Dimensional inspection and material verification as required |

Request a Pump Casting Solution

Partagez vos fichiers de conception, vos dessins ou vos échantillons avec nous. Notre équipe d'ingénieurs étudiera la faisabilité de votre projet et discutera avec vous de la méthode de production la plus fiable.

FAQ

Can investment casting be used for pump components?

Yes. Investment casting is widely used for manufacturing pump components such as pump casings, housings, impellers, and diffusers. The process allows complex internal flow passages to be formed in one piece while maintaining good dimensional consistency.

What pump parts are typically made by investment casting?

Common investment cast pump components include pump housings, casings, impellers, diffusers, covers, and bearing housings. These parts often benefit from near-net-shape casting and reduced welding or fabrication.

Are pump castings CNC machined after investment casting?

Yes. Investment cast pump components are typically CNC machined after casting. Machining is applied to functional features such as sealing faces, bearing bores, shaft interfaces, and threaded holes to meet dimensional and assembly requirements.

What tolerances can be achieved for investment cast pump parts?

Dimensional tolerances depend on part geometry, material, and feature type. Investment casting provides near-net-shape accuracy, while CNC machining is used to achieve tighter tolerances on critical functional areas as specified in customer drawings.

Do you supply complete pump assemblies?

No. We focus on manufacturing custom pump components by investment casting and CNC machining. Complete pump assemblies are not supplied.

Do you support prototype or low-volume pump casting projects?

Yes. Prototype, pilot, and small to medium batch production are supported. Tooling and process planning are evaluated based on part complexity, material selection, and required quantities.