Custom Casting Solutions for Spider Fitting Manufacturing

Leveraging our expertise in precision casting and CNC finishing, HDC provides custom manufacturing services for constructors and brands who are seeking non-standard spider fitting builds to their design.

Que peut offrir HDC ?

Custom Casting Blanks

HDC supports custom spider fitting blanks based on your design or sample. Only necessary trimming and polishing are applied. Best suited for manufacturers capable of in-house finishing.

Precision Finishined Parts

Besides casting, HDC also offers CNC service for well-finished spider fitting arms. We can finish critical mounting holes and surfaces to fit your existing accessories, or replace old spider fittings.

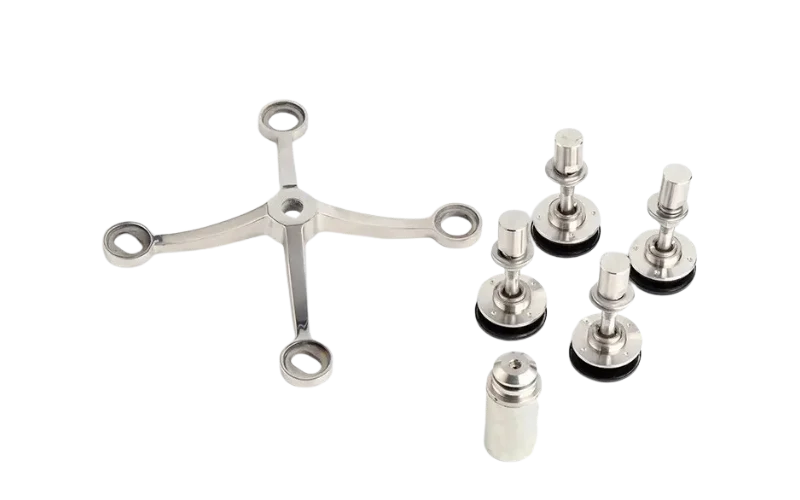

Fully-Assembly Sets

HDC can also provide one-stop OEM solutions from casting and CNC machining to accessory customization with our mature supply chain. You only need to purchase one place to get customized spider fitting assemblies.

Typical Spider Fitting We Can Cast

HDC supports custom design spider fitting manufacturing, covering all your needs regarding structure, function, strength, and material.

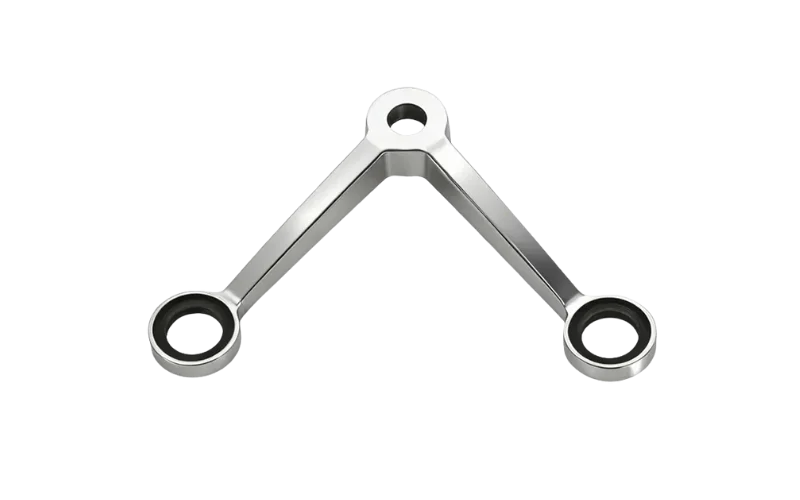

1 Way Spider Fitting

Precision-cast 1 arm fitting, built for edge or corner glass support. HDC can custom with different length to fit your peripheral structural frames.

2 Way Spider Fitting(90°)

Precise angle control through optimized wax mold design and streamlined casting process. We offer custom angle from 30° to 180°.

2 Way Spider Fitting(180°)

Designed for connecting two inline panels, these fittings can be custom cast with high-strength steel to hold panels up to 50kg.

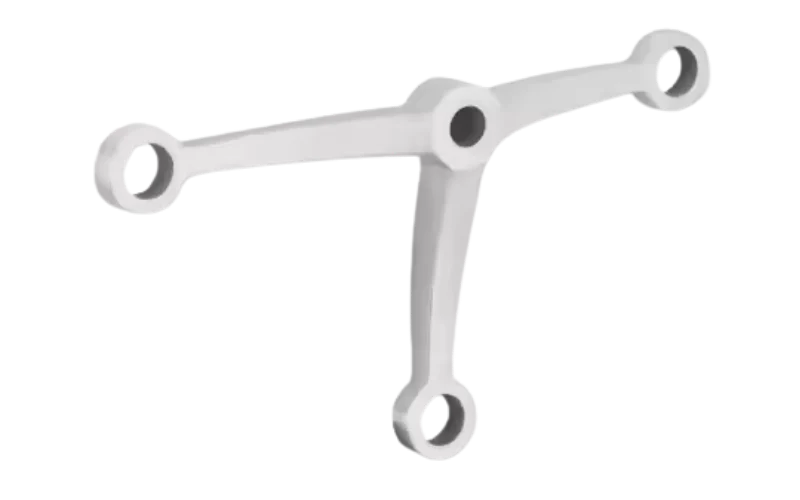

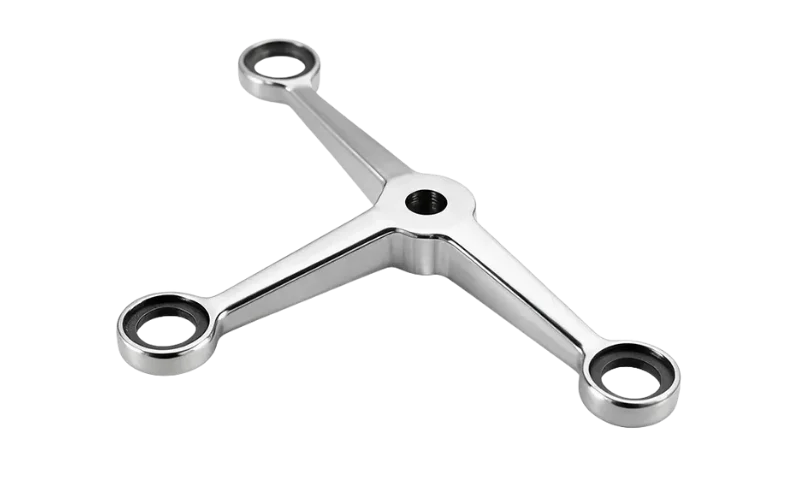

3 Way Spider Fitting

Also known as T-type spider fitting, these components are used at T-junctions to handle asymmetrical structural loads.

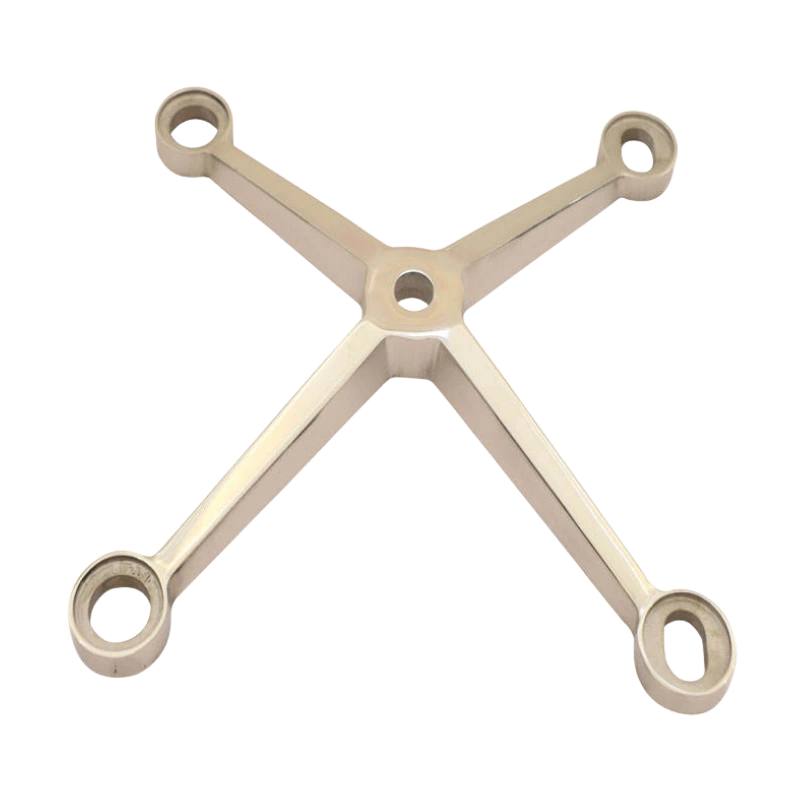

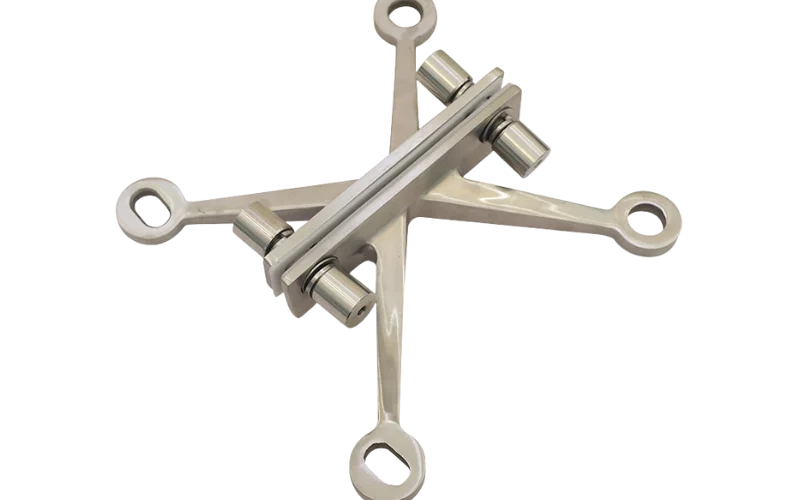

4 Way Spider Fitting

To efficiently connect four panels at a single node, you need casted one-piece design 4-arm spider fitting to handle high load.

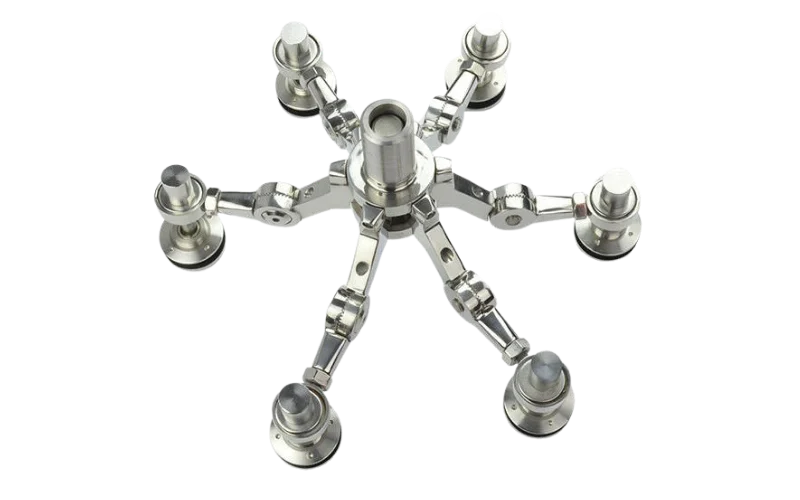

6 Way Spider Fitting

Multi-point spider fitting is specialized for complex 3-dimensional panel connections. At HDC, we support any connection needs with unmatched custom casting capabilities.

K-Type Spider Fitting

This spider fitting is named after the distinct “K” geometry. It’s often used with fin-mounted or post-mounted systems for a modern, industrial aesthetic.

Fin Mount Spider Fitting

To reduce useage of metal columns and achieve the maximum visual integrity of the glass curtain wall. HDC offers custom manufacturing services for these curical component.

Why Investment Casting for Spider Fitting

Our expertise in investment casting allows us to produce custom fittings tailored to your project.

Complex Geometry & Design Freedom

Investment casting is known for its ability to produce metal parts with intricate designs. Whether it’s for visual or functional, HDC will bring your unique spider fitting design into reality.

Superior Surface Finish & Precision

We use fine-grade ceramic molds to achieve a smooth finish right out of the mold. This minimizes secondary polishing and ensures a flawless aesthetic for every component of your glass facade.

High-Performance Material Versatility

You can manufacture spider fittings with almost any types of stainless steel and alloy steel by investment casting, such as SS316 and Duplex 2205, for specific applications.

Cost Effective in Mass Production

With investment casting’s near-net shape production capability, only minimal CNC machining is needed to achieve the desired tolerance for spider fitting.

Capacités de base HDC

How does HDC ensure consistent quality from casting to final product? Here are the answers.

Support technique

We provide professional DFM support to optimize your design for better structural performance and cost-efficiency without compromising your architectural vision.

Solution unique

By combining our in-house investment casting with CNC machining, we offer a seamless production flow from raw materials to final product.

Contrôle de qualité

We deeply understand that safety is non-negotiable in glass facade hardware. So we introduce comprehensive quality control to ensure every component meets safety standards.

Materials for Casting Spider Fitting

Stainless steel is favored in components used in the glass curtain wall system mainly due it’s two advantages: modern shiny appearance and excellent corrosion resistance. One is chosen for seamless integration with glass and metal structure buildings, and another is selected to handle rigorous outdoor environments.

The common grades we offer include 304, 316L, and 2205.

Carbon steel is chosen more because it’s high strength and low cost compared to most stainless steel. But specific surface finishes must be applied to withstand outdoor environments.

We offer a wide range of carbon steel, including 1025 and 1045.

Available Surface Finishes

Combined with in-house finishing capabilities and partners worked with for years, HDC provides surface treatment options below for your custom spider fittings. More options are negotiable if you require.

| 🔷 Brossé | 🔷 Mirror Polish |

| 🔷 Electropolishing | 🔷 Passivation |

| 🔷 Powder Coating | 🔷 Sandblasting / Bead Blasting |

Typical Applications of Spider Fitting

HDC’s precision-cast spider fittings are engineered to support high-transparency glass structures where structural strength and aesthetic elegance are equally vital. Typical applications we support include:

| 🔷 Point-Fixed Glass Curtain Walls | 🔷 Glass Balustrades & Railing Systems |

| 🔷 Structural Glass Bridges & Floors | 🔷 Glass Skywalks & Observation Decks |

| 🔷 Glass Canopies & Entrance Systems | 🔷 Interior Glass Partitions & Showcases |

Start Your Custom Project Today

Looking for a reliable manufacturing partner for your next glass facade? Contact us for a free quote and technical feasibility analysis within 24 hours.

FAQ

What is a spider fitting?

A spider fitting is a point-supported glass fixing component commonly used in modern architectural glazing systems.

It connects glass panels to a supporting structure while maintaining transparency and structural stability.

What are the main components of a spider fitting system?

A typical spider fitting system consists of:

- Spider arms (single, double, or multi-arm)

- Rotules or bolts

- Glass connectors and mounting hardware

Each component works together to transfer loads safely to the supporting structure.

What materials are spider fittings usually made from?

Spider fittings are most commonly made from acier inoxydable, such as SS304 or SS316.

These materials provide excellent strength, corrosion resistance, and durability for both indoor and outdoor applications.

What types of spider fittings are available?

Spider fittings are generally classified by the number of arms, the most common types including:

- Single-arm spider fittings

- Two-arm spider fittings

- Four-arm spider fittings

The selection depends on glass layout, load requirements, and architectural design.

How are spider fittings installed?

Spider fittings are mounted to a supporting structure such as steel beams, concrete, or glass fins.

Glass panels are then connected using rotules, allowing controlled movement to accommodate thermal expansion and structural deflection.

Can spider fittings be customized for different projects?

Yes. Spider fittings can be customized in size, arm configuration, material grade, and surface finish to meet specific project requirements and design standards.

What is the difference between spider fittings and framed glass systems?

Unlike framed systems, spider fittings use point-supported connections instead of continuous frames.

This results in greater transparency, lighter visual appearance, and more design flexibility.