Custom Motorsports Parts Solutions

Turing your design into real products with optimized performance

Focus on custom design and development of metal components, HDC has gained rich experience supporting customers from the motorsports industry.

Whatever you need, we help you achieve optimized results under various constraints, from weight and strength to precision, turning your ideas into high-performance, track-ready components.

Motorsports Aeras We Serve

From extreme loads and vibrations to the need for lightweight, high-precision components, HDC provides tailored solutions for a wide range of motorsports applications.

Automobile

From performance parts to decorative parts, OEM components to aftermarket modifications, HDC supports all your custom auto parts needs. Including:

- Suspension Components

- Wheel Accessories

- Pièces décoratives

Moto

Backed by advanced forging and CNC machining capabilities, HDC manufactures motorcycle parts that are both strong and precise to meet your requirments, which include:

- Cadres

- Body Parts

- Brake & Clutch Components

Karting

HDC started with the manufacturing of CNC go-kart parts and has been deeply involved in this field for over a decade. We are experts in fabricating:

- Control and Steering Parts

- Moyeu de roue

- Pièces de moteur

Pourquoi choisir HDC

HDC is not only a supplier, but we are a partner who can help to grow your business from small to global.

Focus in Motorsports Industry

We don’t just manufacture according to your design — we support optimization and iteration for motorsports projects.

Multiple Processes, One Solution

Casting, forging, CNC machining, and surface finishing are combined to deliver optimized results for each application.

Performance & Aesthetics in Balance

We understand that motorsports parts must perform under extreme conditions while meeting visual and branding requirements.

From Prototype to Production

Support for low-volume prototypes, track testing iterations, and stable batch production.

Manufacturing Solutions

Different materials and performance targets require different manufacturing approaches. HDC combines multiple processes to deliver optimized motorsports parts.

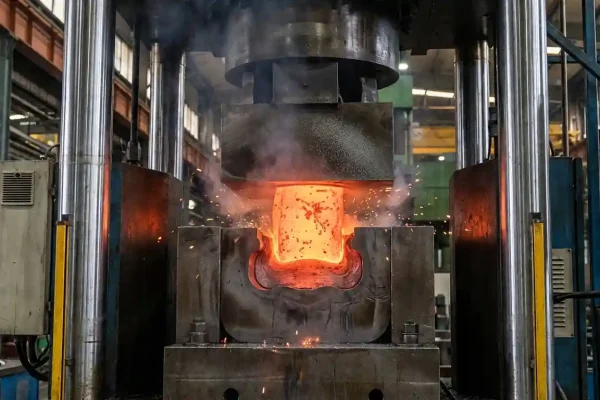

Forging for Strength

- Optimized grain flow

- Improved strength-to-weight ratio

- Ideal for safety-critical components

Applications courantes :

Control arms, suspension parts, load-bearing structures

Casting for Complex Shapes

- Suitable for complex internal geometries and hollow structures

- Efficient for medium-volume motorsports parts production

Applications courantes :

Exhaust components, housings, covers

CNC Machining for Precision

- Tight tolerances

- Ideal for complex geometries and custom designs

- Fast iteration for development and testing

Applications courantes :

Wheel spacers, hubs, brackets, triple trees

Material Solutions for Motorsports Applications

High-quality materials are the basis of high-quality motorsports parts. HDC provides a wide range of materials for your custom project. Meanwhile, we also support the most suitable corresponding processing method for manufacturing parts from raw material.

| 🔷 Stainless Steel | 🔷 Aluminum Alloy |

| 🔷 Forged Aluminum | 🔷 High-Strength Alloy Steel |

| 🔷 Acier au carbone | 🔷 Carbon Fiber |

- Excellent strength-to-weight ratio

- Ideal for reducing unsprung and rotating mass

- Easy to adapt for custom shapes and designs

- Improved fatigue resistance under cyclic loads

- More reliable for safety-critical components

- Preferred choice for high-performance suspension parts

- Superior load-bearing and impact resistance

- Stable performance under aggressive racing conditions

- Selected when safety margins are the top priority

- Reliable mechanical strength for demanding applications

- Suitable for parts where weight is less critical

- Practical choice for performance-focused builds with budget control

- Excellente résistance à la corrosion

- Suitable for high-temperature or harsh environments

- Clean appearance for exposed components

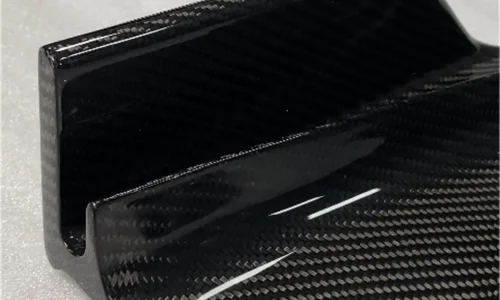

- Extremely low weight with high rigidity

- Strong visual impact for custom and premium builds

- Ideal for both functional and aesthetic upgrades

Typical Motorsports Parts We Deliver

Real industry experience is not just talk. Below are projects we serving motorsports industry in recent years.

Forged Suspension Parts

Forged with high-strength aluminum, our control arms and links are built for racing car modification and OEM replacement, ensuring improved performance and durability.

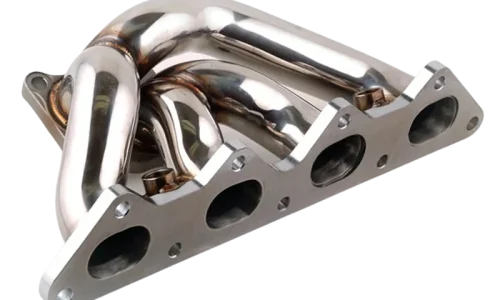

Collecteur d'échappement

We manufacture these complex components through precision casting (Investment Casting), available in custom design or reverse engineering.

Entretoise de roue et adaptateur

Spacer & adapter is one of our major products in the auto industry. We combine the strength of forging and the precision of CNC, reaching an annual production of 300,000 units.

Moyeu de roue de moto

Forge for the blank and CNC for the crucial geometries and mounting holes. These crucial motorcycle parts are made for performance models and competitive racing.

Pince triple pour moto

Engineered using high-density forging and multi-axis CNC, our triple clamps provide the perfect balance of rigidity and weight reduction for superior front-end feedback.

Control Levers & Pedals

We utilize 6061-T6 aluminum forging to ensure maximum fatigue resistance, delivering responsive brake and shift feel that stands up to the rigors of professional racing.

Pignon de kart

Our karts sprockets are crafted with tight-tolerance and specialized surface hardening, ensuring optimal power transfer and extended chain life under high-RPM loads.

Kart Wheel Hub

By combining a solid forged base with precise CNC finishing, our hubs provide a perfect fit and zero wobble. They are built to handle high speeds while keeping your kart stable.

How to Work With HDC

- Step 1 – Quoting: Share your drawings, samples, or performance targets.

- Step 2 – Engineering & DFM Analysis: We help to optimize your design for the best balance of weight, strength, and cost-efficiency.

- Step 3 – Prototyping: We built the sample for you to validate, ensuring 100% fit with your project requirements.

- Step 4 – Production: Once the sample is approved, we move to mass production.

- Step 5 – Delivery: Flexible batch sizes, reliable lead times, and long-term support for upgrades or revisions.

Have a Motorsports Project in Mind?

Talk to our engineering team about your custom parts. Share your drawings, samples, or performance targets, and our engineering team will help define the right solution.

FAQ

What types of customization does HDC accept?

We support both custom design based on your drawings and reverse engineering from physical samples. If you have an idea, a sketch, or a finished part, we can help turn it into production-ready components.

What design file formats can I submit?

We work with most industry-standard formats. STEP, IGS, and STL are the best for CNC machining, but we can also review PDF drawings or even clear hand sketches to get the conversation started.

What materials do you offer for motorsports parts?

We specialize in high-performance racing materials. This includes all grades of aluminum (like 6061, 7075), carbon steel, stainless steel, titanium and even carbon fiber for those weight-critical parts.

What machining tolerances can you achieve?

Through CNC machining, typical tolerances can reach ±0.01 mm, with tighter tolerances available for critical features depending on design and material.

Do you provide surface finishing services?

Yes. We offer a range of surface finishes including anodizing, hard anodizing, powder coating, polishing, bead blasting, and plating, depending on material and application.

What is your typical minimum order quantity (MOQ)?

MOQ depends on the part type and manufacturing process. We support low-volume prototyping as well as stable batch production for motorsports projects.