Investment casting wax is easy to underestimate because it never becomes part of the final metal component. But in moulage à la cire perdue, the wax pattern is the master shape that the ceramic shell copies. That means the wax controls more than people expect: dimensional accuracy, surface finish, repeatability, and even how much CNC machining is needed to meet the drawing. If the wax pattern shrinks inconsistently, warps, cracks, or carries surface defects, those issues typically show up later as scrap, rework, and additional finishing cost.

This article explains investment casting wax in a practical, sourcing-friendly way. You’ll see what the wax does in the process, what wax types exist, which properties matter most, what defects to watch for, and how wax choice connects directly to surface finish and machining time.

What Is Investment Casting Wax?

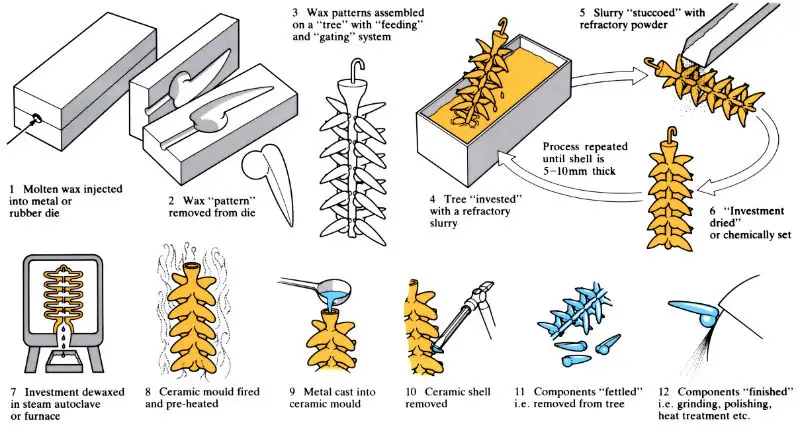

Moulage de précision wax is the pattern material used to create a wax replica of the final part. In most production setups, wax is injected into a metal die to make a precise pattern, then multiple patterns are assembled onto a tree with runners and gates. That assembly is coated in ceramic slurry and stucco to build a hard shell. Once the shell reaches strength, the wax is removed during dewaxing, leaving a hollow ceramic mold. Molten metal fills that cavity, creating the casting.

Because the shell reproduces the wax surface and geometry, any wax instability becomes a downstream problem. The wax stage is essentially where the process “locks in” shape and finish quality.

Why Investment Casting Wax Matters So Much

The reason buyers should care about investment casting wax is simple: wax behavior determines how stable the pattern is across time and handling, and that stability influences how consistent the final castings are from run to run. Even small variation in wax shrinkage or distortion can shift critical datums, change wall thickness in sensitive areas, or produce surface texture issues that require extra finishing.

This also matters for lead time and cost. A clean, dimensionally stable wax pattern usually means fewer shell issues, fewer casting defects, and less rework. And when the casting starts closer to spec, machining becomes lighter and faster—especially for sealing faces, bearing seats, threads, or tight bores.

Types of Investment Casting Wax

In real foundry workflows, “wax” is not one thing. Different wax formulations are used depending on whether you’re creating the part pattern, building the gating system, or assembling the tree.

The main material is pattern wax, which is used for injection molding the actual part shape. Pattern wax is designed to fill fine details, release cleanly from the die, and shrink in a predictable way so dimensions can be controlled. Alongside that, foundries commonly use runner and sprue wax for the gating system, which is often selected for toughness and handling strength because it must survive assembly and shell building without cracking. For joining patterns and repairing small connection points, sticky wax is used as an assembly aid because it sets quickly and holds reliably. Some projects also use soluble wax when internal cavities or complex passages are involved and a removable wax “core” makes more sense than other core strategies. You may also hear about filled waxes, where additives are used to improve stiffness, reduce shrink effects, or tune thermal behavior—useful when stability is critical, but it requires tighter control to avoid surface or residue issues.

What to Look For When Choosing Investment Casting Wax

When people talk about “wax quality,” they’re usually describing a combination of flow, shrinkage behavior, mechanical strength, thermal response, and cleanliness during dewaxing. The right choice depends on your geometry and the tolerance sensitivity of your design, but the principles are consistent.

Start with flow and injection behavior. If the wax doesn’t flow well, you’ll see incomplete fill on thin sections, flow lines, and surface streaks that the ceramic shell will faithfully reproduce. Then there’s shrinkage and dimensional stability, which is often the biggest concern for precision parts. All wax shrinks during cooling; what matters is whether it shrinks consistently and whether the pattern remains stable after it comes out of the die. For tight tolerances, you want predictable shrink and minimal “drift” over time.

Next is strength and toughness, which matters more than it sounds. Wax patterns can be fragile, and thin ribs, edges, or long slender features can crack during ejection, trimming, or tree assembly if the wax is too brittle. The wax also has a melting/softening profile that affects whether patterns distort when handled or stored, especially if shop temperatures fluctuate. Finally, clean burnout and low residue are important because wax that leaves contamination can cause surface defects, shell problems, and additional cleanup.

One more practical factor is reclaim. Many foundries recycle wax, but wax properties can shift when reclaim ratios change or contaminants creep in. For repeatable production, wax blending and reclaim control matter almost as much as the wax formula itself.

How Investment Casting Wax Affects Surface Finish and CNC Machining

Wax quality has a direct link to surface finish because the shell reproduces the wax surface. When the wax pattern is smooth and stable, the casting usually comes out cleaner and closer to final form, which reduces grinding, polishing, and the amount of machining stock you need to remove. This matters a lot when you’re trying to hold a specific finish level on visible surfaces, sealing areas, or mating interfaces.

Wax also affects machining indirectly through dimensional stability. If wax shrinkage is inconsistent, you can get subtle geometry shifts that force heavier machining or even make some tolerances impossible without rework. For many projects, the best cost outcome happens when the wax stage produces a near-ideal pattern and the machining stage is reserved for the truly functional features.

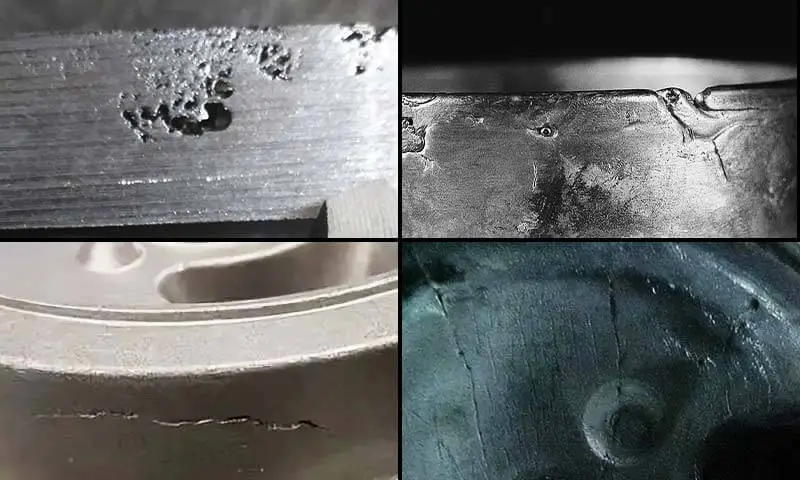

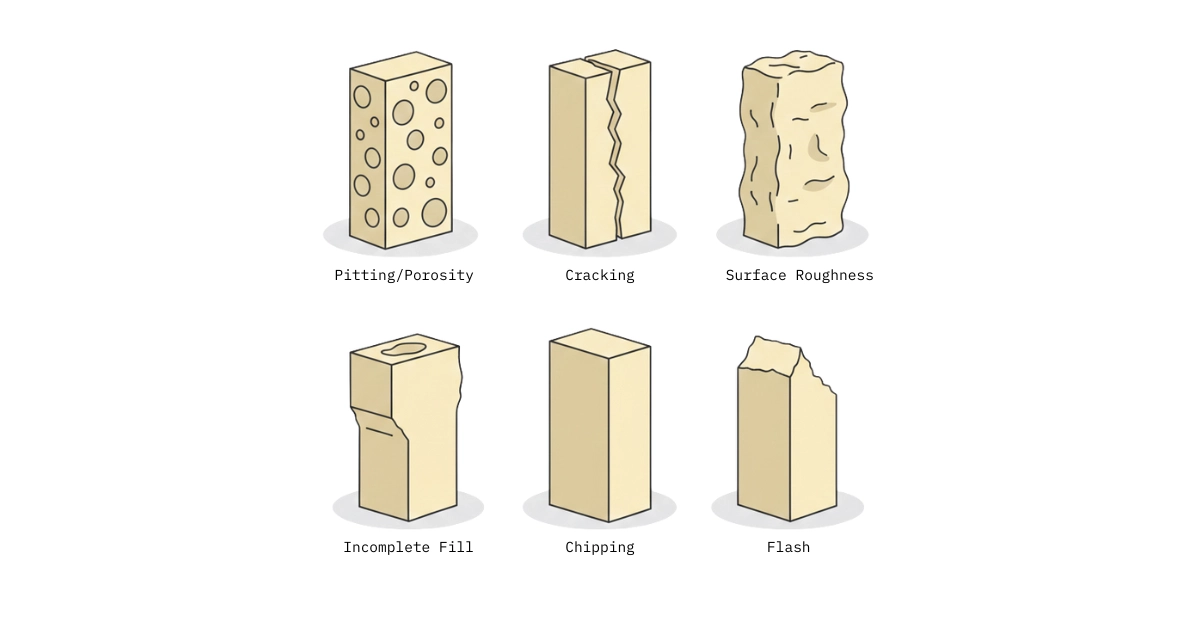

Common Wax Pattern Defects and What They Usually Indicate

Wax issues tend to show up in predictable ways. Warpage and distortion often point to uneven cooling, patterns being ejected too early, wax that’s too soft for the geometry, or poor storage and handling that loads thin sections. Cracking can occur during ejection, trimming, or assembly and is often linked to brittle wax, high internal stress, or rough handling before the pattern stabilizes.

Surface-related defects are also common. Flow lines and streaks often suggest that the wax flow or injection conditions are not well tuned, or that venting and die temperature are not controlled. Sink marks and internal voids frequently relate to thick-to-thin transitions, packing behavior during injection, or cooling patterns that pull the surface inward. Poor release or drag marks are typical when the wax and tooling interaction isn’t optimized, which can deform patterns and shift dimensions. The key point is that wax defects do not stay “at the wax stage”—they become shell issues, casting issues, or machining cost later.

Handling and Storage: The Quiet Source of Variation

Even when the wax formula is correct, inconsistent handling can create variation. Wax patterns behave differently immediately after injection versus after they’ve fully cooled and stabilized. If patterns are measured too early, stacked carelessly, exposed to heat sources, or bent under their own weight in storage, dimensions can drift and defects can appear without anyone changing the injection settings.

Stable production typically comes from consistent injection parameters, controlled cooling time, careful pattern handling, and controlled reclaim ratios. In other words, process discipline often matters as much as the wax itself.

What to Specify When You’re Sourcing Investment Cast Parts

You don’t need to buy wax directly to benefit from understanding investment casting wax. If your part has tight tolerances, thin walls, or finish-sensitive surfaces, it helps to call that out early. That pushes the supplier to pay attention to wax injection control, pattern stability time, and reclaim management rather than treating wax as a commodity.

It also helps to align early on what is cast-to-finish and what will be machined. When both sides agree on which surfaces are “as-cast” and which are “machined,” the wax and pattern strategy becomes much easier to optimize for cost and quality.

FAQ: Investment Casting Wax

What is investment casting wax used for?

Investment casting wax is used to create the wax pattern, which forms the exact shape that the ceramic shell copies before metal is poured.

Is investment casting wax the same as lost wax casting wax?

Yes. “Lost wax casting” is the common name for investment casting, and the wax refers to the pattern material that is removed during dewaxing.

What wax is best for precision investment casting?

For precision work, the best investment casting wax is typically one with predictable shrinkage, strong dimensional stability after cooling, clean die release, and low residue behavior. The best choice still depends on geometry and process control.

Can investment casting wax be recycled?

Yes, wax is often reclaimed, but reclaim ratios and contamination control must be managed carefully to avoid dimensional variation and surface defects.

What causes wax pattern warpage in investment casting?

Warpage is commonly linked to uneven cooling, early ejection, wax that is too soft for the part geometry, and poor storage that bends thin sections.

Does wax quality affect casting surface finish?

Yes. The shell reproduces the wax surface, so smoother, more stable wax patterns typically produce cleaner castings that need less finishing.

Why do wax patterns crack during handling?

Cracking can come from brittle wax, high stress during ejection, trimming or assembly forces, or handling patterns before they fully stabilize.

How does investment casting wax affect CNC machining time?

Stable wax patterns usually produce more accurate castings with better surfaces, which reduces machining stock, rework, and overall CNC time.

Conclusion

Investment casting wax plays a critical role in controlling dimensional accuracy, surface finish, and overall process consistency. Stable wax patterns lead to more predictable castings, fewer defects, and reduced CNC machining after casting.

At HDC, our service de moulage à la cire perdue focuses on wax pattern control from the start—combining optimized wax selection, controlled injection, disciplined handling, and clear cast-to-machined surface planning. This approach helps customers achieve near-net-shape castings with reliable tolerances, lower post-processing cost, and consistent production results.