Pièces automobiles CNC personnalisées avec HDC

Chez HDC, nous utilisons une technologie CNC avancée pour fabriquer vos pièces automobiles sur mesure. Forts de 15 ans d'expérience en tant que fabricant professionnel de pièces métalliques, nous privilégions la précision et la qualité, et nous sommes reconnus par des centaines de clients du monde entier.

L’un de nos principaux domaines d’activité est l’industrie de la course automobile. Nous fabriquons des pièces détachées automobiles et des pièces de performance depuis plus de dix ans.

Production à faible volume

Délai d'exécution rapide

Expédition mondiale

Certificat ISO 9001

Avantages des pièces automobiles CNC

Conception complexe

Vous pouvez fabriquer des pièces automobiles avec une conception complexe grâce à la technologie CNC, sans investissement initial comme les moules.

Ajustement parfait

Une pièce personnalisée est conçue pour un modèle spécifique, vous n'avez donc pas à vous soucier de l'adaptabilité.

Une qualité incomparable

L'usinage CNC peut atteindre une précision et une qualité de surface élevées sans post-traitement supplémentaire.

Pièces de moteur automobile CNC

Couvercle de soupape

Usiné CNC à partir d'un bloc d'aluminium billette, léger et durable, il aide à sceller le train de soupapes, empêche les fuites d'huile et protège les composants internes de la contamination.

Protection du bloc moteur

Support en aluminium usiné avec précision pour moteur à pont ouvert, aide à empêcher la déformation du manchon du cylindre pendant les régimes élevés, également connu sous le nom de protège-manchon.

Bouchon de vidange magnétique

Fabriqué en aluminium avec des filetages de précision, un aimant est installé à l'extrémité, aidant à éliminer les petits morceaux de métal de l'huile moteur et à réduire les dommages au filtre à huile.

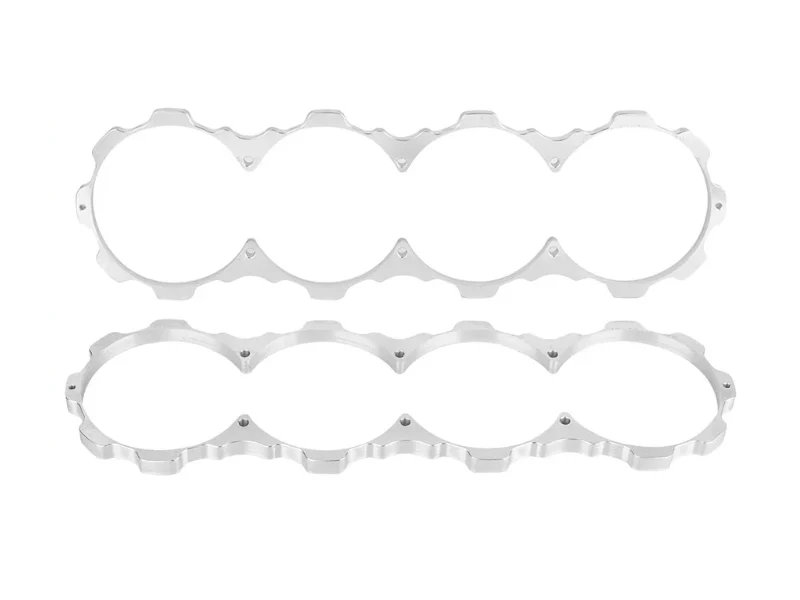

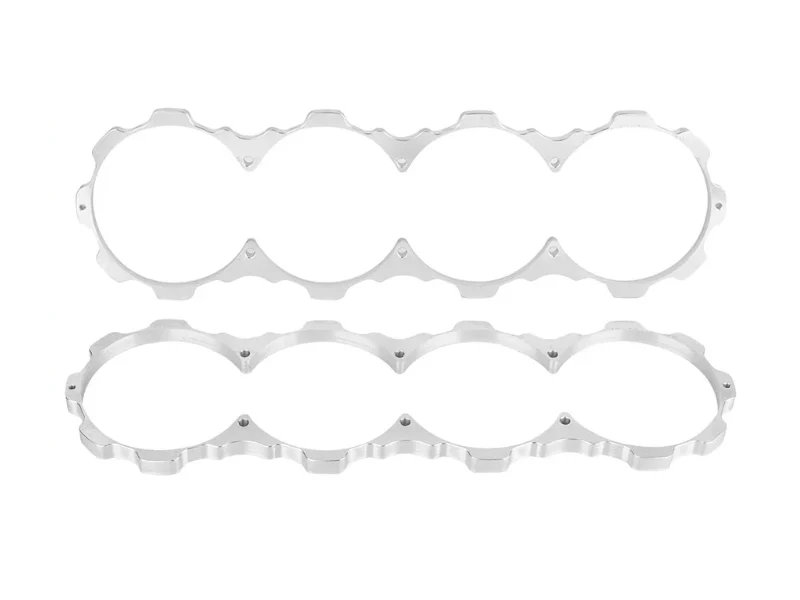

Bride de collecteur d'admission

Fabriqué en aluminium usiné CNC, il assure la liaison entre le collecteur d'admission et le corps du moteur. Sa fonction principale est d'assurer l'étanchéité du système d'admission.

Pièces de rechange CNC pour voitures

Écrous en titane

Fabriqués en alliage de titane haute résistance, ils sont disponibles en différentes formes et tailles. Ils conviennent parfaitement au remplacement des écrous cassés.

Boulons en titane

Fabriquées à l'aide de la technologie CNC, ces vis en titane peuvent être personnalisées à n'importe quelle forme et taille pour des applications hautes performances ou pour remplacer les anciennes.

Boîtier de batterie

Usiné CNC avec de l'aluminium, ce boîtier de batterie peut être personnalisé pour s'adapter à n'importe quel modèle de voiture, il est léger et peut fixer fermement la batterie pendant une conduite intense.

Jauge

Fabriquée en alliage d'aluminium, cette jauge peut être personnalisée avec n'importe quelle forme pour améliorer l'expérience de prise de vue et anodisée avec plusieurs couleurs pour s'adapter à vos préférences.

Arrêt du levier de vitesses

Usiné CNC à partir d'aluminium usiné, avec plusieurs couleurs anodisées. Il sert à limiter la plage de mouvement latéral ou longitudinal du levier de vitesses.

Pommeau de levier de vitesse

Nous utilisons la découpe CNC de l'aluminium pour produire des pommeaux de levier de vitesse parfaitement adaptés à votre design. Cela améliorera considérablement l'expérience et la précision du changement de vitesse.

Entretoise de ventilation de capot avant

Pièces en aluminium usinées CNC petites et simples mais efficaces qui peuvent aider votre moteur à obtenir de l'air plus frais et à maintenir le moteur à ses meilleures performances.

Pièces de roue de voiture CNC

Roue en aluminium billette

Ces roues sont usinées CNC à partir d'une pièce entière d'aluminium, très résistantes et légères, peut-être chères mais qui en valent vraiment la peine.

Entretoise de roue

Faites confiance à HDC pour vos entretoises de roue personnalisées. Nous les fabriquons par usinage CNC et avec les meilleurs aluminiums 6061 et 7075. C'est notre pièce automobile la plus vendue.

Entretoise de jambe de force

Une entretoise de structure ressemble à une entretoise de roue et sert à surélever le véhicule. Nous la fabriquons selon le même procédé et avec le même matériau.

Écrou de roue

Chez HDC, nous fabriquons des écrous de roue sur mesure à partir de votre plan ou échantillon. Vous pouvez choisir l'aluminium ou le titane pour une résistance accrue.

Pourquoi choisir les pièces automobiles CNC HDC

- Expérience: Plus de 10 ans d'expérience dans la personnalisation de pièces automobiles CNC.

- Précision: Nous sommes en mesure de fournir des tolérances jusqu'à ± 0,005 mm.

- 50+ Matériaux : Nous fournissons plus de 50 matériaux pour vos produits personnalisés.

- 10+ Finitions : Nous proposons l'anodisation, le placage, le revêtement en poudre, etc.

- Pas de MOQ : Aucune quantité minimale de commande pour les pièces automobiles CNC personnalisées.

- Production en grand volume : Nous pouvons gérer une production de masse jusqu'à 10 000 par mois.

- Coût inférieur : Pas de MOQ, vous pouvez obtenir une remise avec de grandes quantités.

- Livraison rapide: La production et la livraison sont réalisées en 1 semaine seulement.

Notre usine

Notre usine de 2 500 m² est équipée de plus de 30 machines CNC, dont 20 machines CNC 3 axes, 8 centres d'usinage 4 axes et 2 systèmes CNC 5 axes. Outre la machine d'usinage, nous disposons également d'une machine à usinage tridimensionnel (MMT) et d'un appareil de mesure de dureté et de rugosité pour le contrôle qualité.

Nous comptons 50 employés, dont des ingénieurs, des concepteurs, des opérateurs de machines, des équipes de contrôle qualité et de vente. Nous sommes en mesure de prendre en charge des commandes d'usinage CNC sur mesure de toutes tailles.

Comment nous produisons des entretoises de roue

Nous produisons de nombreux types de pièces automobiles de rechange, dont les entretoises de voie sont notre produit le plus populaire. Voici comment ces entretoises sont fabriquées.

Entretoise de roue en cours d'usinage

Comme nous le savons tous, la résistance est essentielle pour une entretoise de voie. C'est pourquoi la plupart de nos ébauches sont fabriquées en aluminium 7075 par forgeage. Notre fournisseur de pièces forgées en aluminium produit ces ébauches selon nos spécifications de dessin. Nous utilisons l'usinage par tournage pour une finition précise et conforme aux normes dimensionnelles, puis nous utilisons le fraisage CNC pour le perçage des trous de boulons.

Solution unique de pièces automobiles CNC personnalisées

Cliquez simplement sur le bouton « Obtenir un devis instantané », remplissez le formulaire avec vos informations, décrivez clairement vos besoins et joignez des plans ou des photos si vous en avez. Vous recevrez notre réponse sous 24 heures.

Pas de MOQ pour les pièces CNC, mais le prix d'une seule pièce de personnalisation sera plus élevé.

Nous accordons des remises pour les commandes importantes. Vous pouvez discuter en détail du taux de remise avec notre équipe commerciale lors du processus de commande.

Nous proposons différents modes de paiement, notamment virement bancaire, crédit documentaire, virement bancaire et PayPal. Pour tout autre besoin de paiement, veuillez contacter notre service commercial.

Nous proposons des services de transport maritime, aérien et ferroviaire. La livraison express peut être effectuée par DHL, UPS, etc. Sans exigence particulière, nous choisirons le mode de livraison approprié en fonction de la date de livraison convenue et de votre adresse. Les frais de port sont à la charge du client.

Oui, nous proposons un service FOB. Notre équipe gère le dédouanement à l'exportation et la réservation des navires, tandis que vous gérez la suite de l'expédition. Nous proposons également des options CIF/DDP pour une logistique simplifiée.

Produits connexes

Des aubes de turbine

Nous utilisons l'usinage 5 axes et des alliages spéciaux pour produire ces aubes de turbine, qui peuvent rester équilibrées pendant la rotation à grande vitesse et résister à des températures de plusieurs centaines de degrés.

Bras de suspension

Comme pour les bras de suspension, nous obtenons des bras de suspension bruts forgés auprès de notre fournisseur, puis les usinages CNC sont réalisés. Nous allions résistance et précision dans un seul produit.

Bras de suspension du châssis

Forgé en alliage d'aluminium, ce bras de suspension est extrêmement robuste tout en restant léger. Notre fournisseur de pièces forgées fournit l'ébauche brute, et nous utilisons la CNC pour l'usinage de précision.