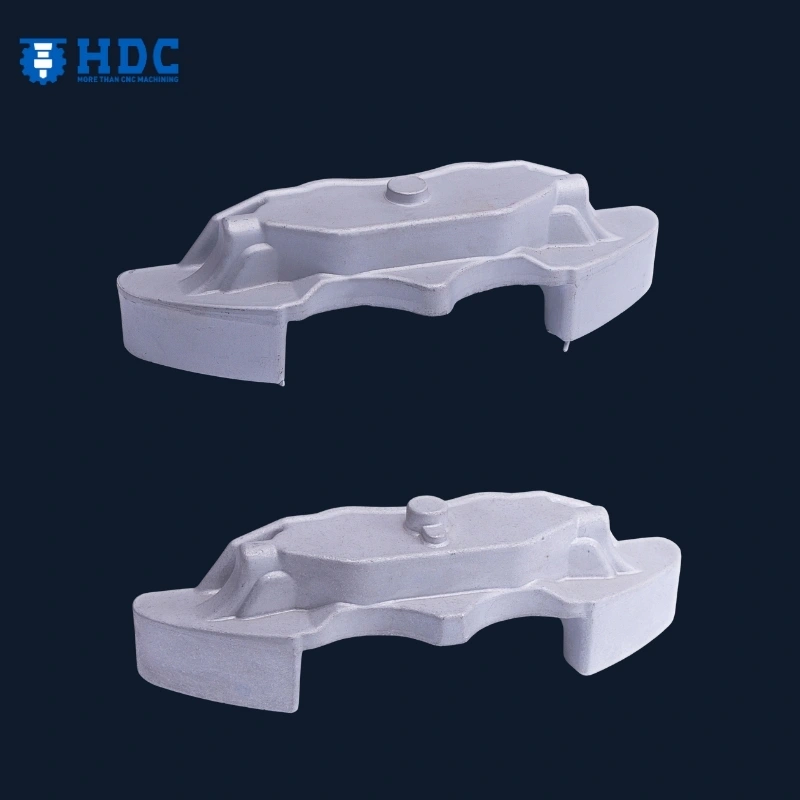

Roue excentrique cylindrique forgée à chaud en acier au carbone de précision pour pièces de machines

Détails du produit personnalisé

| Numéro de modèle. | HDCWCC001 |

| Style | Roue excentrique forgée |

| Matériel | Acier au carbone, alliage d'acier |

| Type de finition | Brut, poli, anodisé, revêtu par électrophorèse, revêtu de poudre, galvanisé, chromé, oxydé noir |

| Taille disponible | / |

| MOQ | 100 pièces |

| Logo personnalisé | Disponible |

| Origine | Chine |

| Emballage et livraison | |

| Option d'expédition | Courrier, air, mer, chemin de fer express, EXW, FOB, CIF, DDU, DDP |

| La date de livraison | 25-30 jours |

| Forfait Transport | Personnalisé, Carton, Palette |

Orchestrez un mouvement mécanique précis sous des charges cycliques extrêmes grâce à cette roue excentrique et cette came cylindrique forgées à chaud avec précision. Conçu pour les systèmes d'automatisation et de transmission à forte charge, ce composant transforme une entrée de rotation en une sortie linéaire ou oscillante parfaitement synchronisée, avec la précision d'orientation du grain que seul le forgeage en matrice fermée peut garantir.

Forgeage en acier au carbone de qualité supérieure: Forgé à chaud à partir d'acier au carbone de haute qualité, ce procédé permet d'obtenir une orientation des grains continue et ininterrompue qui suit le contour excentrique et les profils des lobes de came, offrant ainsi une résistance à la fatigue supérieure par rapport aux alternatives usinées à partir de billettes ou coulées.

Fidélité du profil CNC 5 axesUsinage de finition sur équipement CNC 5 axes pour maintenir une précision de profil, un calage des lobes et des tolérances de concentricité rigoureux, essentiels pour un fonctionnement à grande vitesse sans vibrations.

Durcissement de surface disponibleDisponible en option avec des traitements de cémentation, de trempe par induction ou de nitruration, augmentant considérablement la durabilité de la surface tout en préservant la ténacité ductile du noyau forgé.

Géométrie entièrement personnalisableFabriqués selon les profils, les courbes de levée et les configurations d'alésage spécifiques au client, permettant de répondre aux exigences de synchronisation, aux dimensions d'interface et aux intégrations de montage non standard.

Fiabilité cyclique à charge élevéeConçu pour résister aux chocs répétés, au contact glissant continu et aux températures de fonctionnement élevées sans écaillage prématuré ni dégradation géométrique.

Applications:

Systèmes d'automatisation et d'indexation: Idéal pour les unités de prélèvement et de placement, les tables rotatives et les machines d'assemblage à cames nécessitant des profils de mouvement précis et répétables dans des cycles de service continus.

Systèmes de transmission industriels: Convient aux convoyeurs robustes, aux équipements d'emballage et aux mécanismes d'entraînement spécialisés exigeant une transmission de couple élevée et une sortie synchronisée.

Actionnement mécanique personnalisé: Essentiel pour la fabrication de machines uniques, la modernisation de cellules d'automatisation ou le développement de prototypes nécessitant une géométrie de came non standard et une intégrité des matériaux vérifiée.

Bien plus qu'un simple profil mécanique, cette came excentrique forgée est l'interprète programmé de l'énergie de rotation, convertissant une entrée constante en une sortie précisément dosée à chaque tour. Que vous conceviez des lignes d'emballage à grande vitesse ou des systèmes d'actionnement industriels lourds, c'est le composant qui garantit la précision de votre profil de mouvement, même longtemps après que d'autres pièces soient hors spécifications.