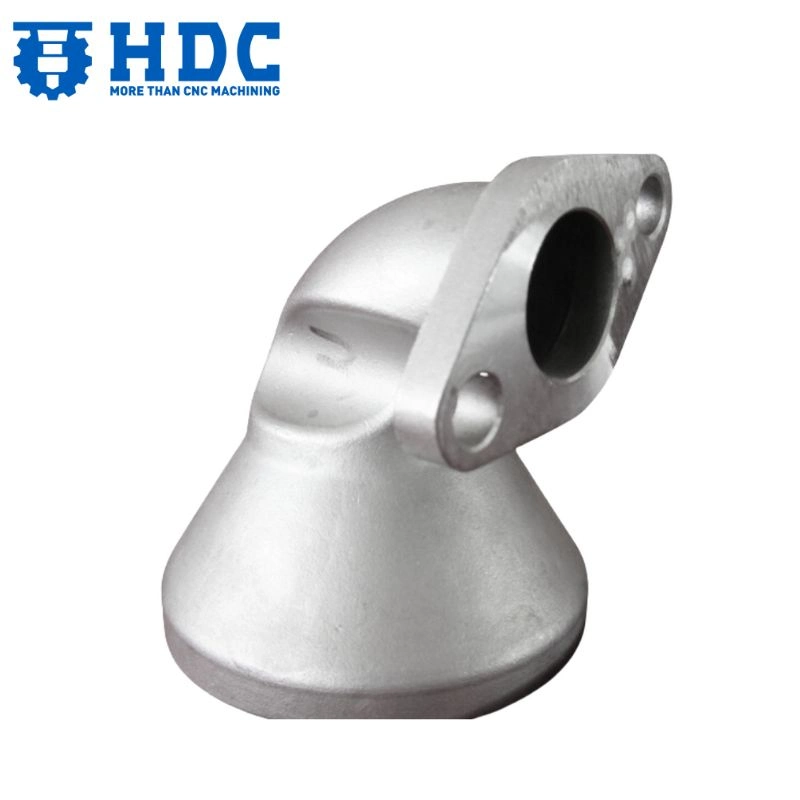

Raccord de tuyau moulé par investissement, connecteur de tuyau à vide, raccord de conduite de carburant

Détails du produit personnalisé

| Numéro de modèle. | HDCIHC001 |

| Style | Raccord de tuyau forgé |

| Matériel | Aluminium, alliage d'aluminium, acier, alliage d'acier, acier inoxydable, superalliage |

| Type de finition | Brut, poli, anodisé, revêtu par électrophorèse, revêtu de poudre, galvanisé, chromé, oxydé noir |

| Taille disponible | / |

| MOQ | 50 pièces |

| Logo personnalisé | Disponible |

| Origine | Chine |

| Emballage et livraison | |

| Option d'expédition | Courrier, air, mer, chemin de fer express, EXW, FOB, CIF, DDU, DDP |

| La date de livraison | 25-30 jours |

| Forfait Transport | Personnalisé, Carton, Palette |

Ensure absolute system integrity across every fluid, fuel, and vacuum line with this investment-cast hose coupling. Precision-engineered for applications demanding leak-free reliability, corrosion resistance, and unimpeded flow, this coupling transforms critical connection points into confidence-inspiring interfaces—delivered with the geometric freedom and material purity only investment casting can provide.

Polyvalence des matériaux multi-alliages: Available in lightweight aluminum, high-strength steel alloy, corrosion-resistant stainless steel, or advanced superalloy—each precision-selected to match specific fluid compatibility, operating pressure, and environmental exposure requirements.

Investment-Cast Complex Geometry: Precision investment casting enables intricate internal profiles, integrated barb contours, and thin-wall weight optimization unattainable through traditional machining or fabrication—eliminating secondary assembly and potential leak paths.

Leak-Free Precision Interface: Micrometer-accurate sealing surfaces and exacting dimensional tolerances ensure consistent compression, O-ring retention, or threaded engagement without deformation or stress cracking during installation.

Smooth Interior Flow Performance: Cast-in smooth bore finishes minimize fluid turbulence and pressure drop while preventing contaminant entrapment—critical for clean-flow fuel, coolant, vacuum, and pneumatic systems.

Longévité et résistance à la corrosion: Alloy-specific heat treatments and passivation processes deliver exceptional resistance to galvanic corrosion, pitting, and chemical degradation in aggressive operating environments.

Configuration entièrement personnalisable: Manufactured to customer-specific end fitting styles, hose retention methods, port geometries, and packaging constraints—accommodating everything from high-volume OEM production to bespoke specialty applications.

Applications:

Automotive Fluid Systems: Ideal for fuel delivery, coolant circulation, brake hydraulics, and EV thermal management lines requiring vibration-resistant, pressure-rated connections.

Industrial Process Equipment: Essential for chemical transfer, pneumatic controls, lubrication circuits, and vacuum systems demanding verified leak integrity and material compatibility.

Aerospace & Specialty Vehicles: Suitable for motorsport, marine, and lightweight prototype applications where every gram and every seal must perform without compromise.

More than a simple fitting, this investment-cast hose coupling is the hydraulic conscience of your fluid system—preserving pressure, containing media, and ensuring every drop arrives exactly where intended. Whether you’re engineering next-generation electric vehicle thermal architecture or industrial process controls, it’s the connection point that proves reliability begins with precision-cast continuity.