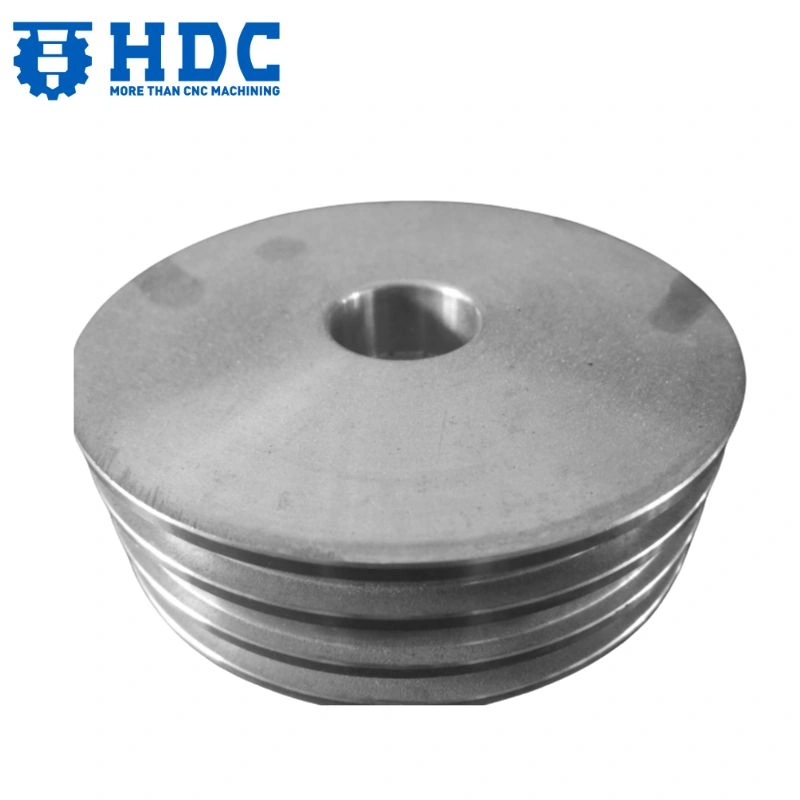

Anneau de buse de turbocompresseur en acier au carbone/aluminium/alliage d'acier moulé de précision

Détails du produit personnalisé

| Numéro de modèle. | HDCINR001 |

| Style | Anneau de buse de turbocompresseur moulé |

| Matériel | Aluminium, alliage d'aluminium, acier, alliage d'acier, acier inoxydable, superalliage, laiton |

| Type de finition | Brut, poli, anodisé, revêtu par électrophorèse, revêtu de poudre, galvanisé, chromé, oxydé noir |

| Taille disponible | / |

| MOQ | 50 pièces |

| Logo personnalisé | Disponible |

| Origine | Chine |

| Emballage et livraison | |

| Option d'expédition | Courrier, air, mer, chemin de fer express, EXW, FOB, CIF, DDU, DDP |

| La date de livraison | 25-30 jours |

| Forfait Transport | Personnalisé, Carton, Palette |

Regulate exhaust energy with surgical precision using this investment-cast turbocharger nozzle ring. Precision-engineered for forced induction systems demanding optimized turbine inlet conditions, this component functions as the aerodynamic throttle between exhaust manifold and turbine wheel—delivered with the vane accuracy and thermal resilience only investment casting can provide.

Multi-Alloy Material Versatility: Available in carbon steel for cost-effective durability, lightweight aluminum for rapid spool applications, or tailored alloy steel for maximum creep resistance and thermal stability—each precision-selected to match specific exhaust gas temperatures, boost pressure targets, and duty cycle requirements.

Investment-Cast Aerodynamic Vane Geometry: Precision investment casting enables the formation of intricately contoured, aerodynamically shaped vanes with continuously blended leading edges and optimized throat areas—unattainable through conventional machining while preserving verified flow coefficient and incidence angle accuracy.

Precise Exhaust Flow Regulation: Strategically configured vane angles and inter-stage channel geometry modulate exhaust gas velocity and entry trajectory into the turbine wheel, optimizing energy transfer across the entire engine operating envelope.

Heat & Creep-Resistant Material Architecture: Alloy-specific heat treatments and solution annealing deliver verified oxidation stability, dimensional retention, and creep resistance during sustained operation in 950°C+ exhaust environments.

Fixed or Variable Geometry Customization: Manufactured to customer-specific vane counts, incidence angles, throat areas, and actuation interface requirements—accommodating fixed-geometry nozzle rings for consistent flow characteristics or variable-geometry designs with articulating vane mechanisms for real-time boost control.

Performance, Economy & Emissions Optimization: Precise exhaust flow management improves turbine efficiency, reducing turbo lag while enabling improved brake-specific fuel consumption and verified emissions compliance through enhanced EGR compatibility and air-fuel ratio stability.

Monolithic Structural Integrity: Single-piece, void-free casting eliminates vane-to-shroud separation and leak paths common to fabricated assemblies, ensuring consistent aerodynamic performance throughout the component’s thermal-mechanical service life.

Applications:

Performance Turbocharger Systems: Ideal for gasoline and diesel applications requiring optimized turbine matching, reduced transient lag, and sustained boost control under high exhaust gas temperature operation.

Commercial Diesel & Heavy-Duty Engines: Essential for on-highway trucks, agricultural equipment, and industrial power units demanding verified fuel economy improvements and emissions compliance.

Variable Geometry Turbocharger (VGT) Integration: Suitable for modern common-rail diesel platforms requiring electronic or pneumatic actuation of nozzle ring vane position for real-time boost pressure modulation.

Turbocharger Remanufacturing & Custom Upgrades: Accommodates hybrid turbo builds, VNT cartridge retrofits, and one-off compressor/turbine housing pairings requiring non-standard nozzle ring geometry with verified flow certification.

More than a stationary vane assembly, this investment-cast nozzle ring is the aerodynamic conscience of your turbocharger—metering exhaust velocity, preserving turbine inlet temperature, and ensuring every pulse of spent combustion gas delivers precisely the energy your engine demands. Whether you’re engineering a fuel-economy-optimized commercial powertrain or a high-specific-output competition engine, it’s the component that proves turbo efficiency begins with precision-cast, aerodynamically vaned continuity.