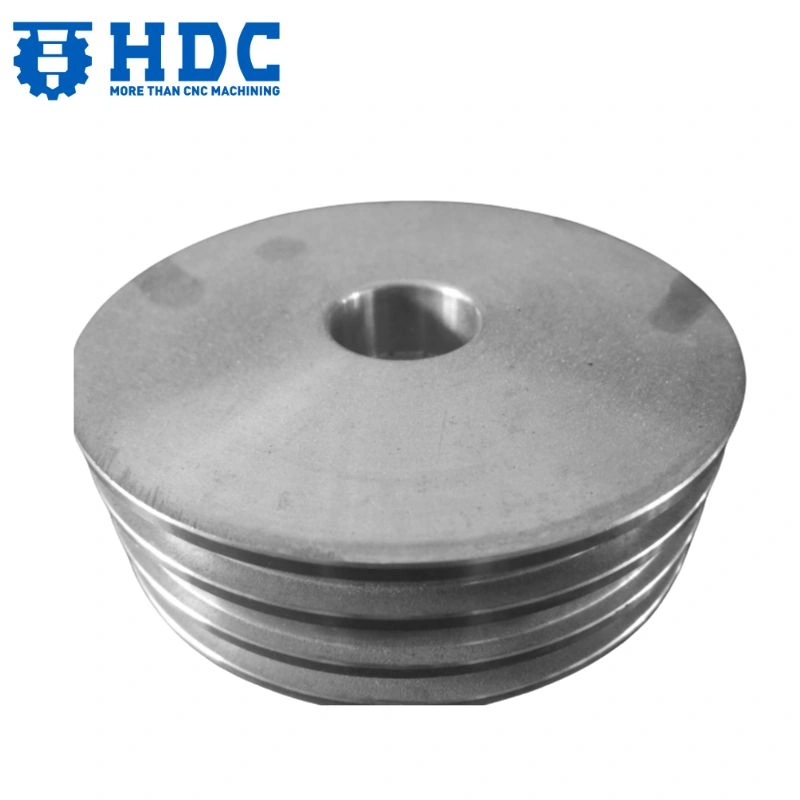

Poulie de courroie de distribution sur mesure en aluminium/acier/superalliage moulée à la cire perdue

Détails du produit personnalisé

| Numéro de modèle. | HDCIBP001 |

| Style | Poulie de courroie moulée à la cire perdue |

| Matériel | Aluminium, alliage d'aluminium, acier, alliage d'acier, acier inoxydable, superalliage, laiton |

| Type de finition | Brut, poli, anodisé, revêtu par électrophorèse, revêtu de poudre, galvanisé, chromé, oxydé noir |

| Taille disponible | / |

| MOQ | 50 pièces |

| Logo personnalisé | Disponible |

| Origine | Chine |

| Emballage et livraison | |

| Option d'expédition | Courrier, air, mer, chemin de fer express, EXW, FOB, CIF, DDU, DDP |

| La date de livraison | 25-30 jours |

| Forfait Transport | Personnalisé, Carton, Palette |

Synchronisez le mouvement et la transmission de puissance avec une précision temporelle absolue grâce à cette poulie de distribution moulée sur mesure. Conçue avec précision pour les systèmes de distribution moteur, les entraînements industriels et les machines de haute précision, cette pièce transforme l'entrée de rotation en une sortie parfaitement synchronisée, offrant la précision du profil des dents et la robustesse monolithique que seule la fonderie de précision peut garantir.

Flexibilité des matériaux multi-alliagesDisponible en aluminium léger pour une masse inertielle réduite, en acier haute résistance pour une capacité de couple maximale ou en superalliage avancé pour les applications à températures extrêmes ou à fonctionnement continu — chaque matériau étant sélectionné avec précision pour correspondre à des facteurs de service, des vitesses de fonctionnement et des conditions environnementales spécifiques.

Profils de dents de précision moulés à la cire perdueLe moulage de précision à la cire perdue permet la formation de formes de dents complexes en développante ou curvilignes, de brides de retenue de courroie et d'une géométrie de moyeu intégrée dans une seule structure monolithique, impossible à réaliser par usinage conventionnel ou assemblage multicomposant tout en préservant la précision du pas AGMA/ISO.

Architecture intégrée monobloc: Consolide le moyeu, la bride, l'âme et le profil de la dent en une seule pièce moulée sans soudure, éliminant ainsi le besoin de vis de blocage, la distorsion des soudures et le fluage des fixations, tout en réduisant le nombre de composants et le travail d'assemblage.

Précision de tir garantie et équilibre dynamiqueLa fidélité de moulage quasi-définitive associée à une finition CNC de précision garantit un espacement constant des dents, un diamètre primitif concentrique et un déséquilibre résiduel minimal, éliminant ainsi les erreurs de synchronisation et les vibrations parasites aux vitesses de fonctionnement nominales.

Potentiel de réduction de poids significatif: La conception de la structure mince et l'enlèvement stratégique de matière moulé directement dans l'ébauche permettent une optimisation de masse poussée sans compromettre la résistance au cisaillement des dents ni l'intégrité de la rétention du moyeu.

Paramètres de conduite entièrement personnalisablesFabriqués selon les spécifications du client en matière de nombre de dents, de largeur de courroie, de diamètre d'alésage, de géométrie de rainure de clavette et de schéma de boulonnage de montage, ils s'adaptent à tout, des systèmes de distribution de moteurs OEM à grand volume aux applications de transmission de puissance industrielle sur mesure.

Durabilité de surfaceDisponible avec des revêtements optionnels d'anodisation dure, d'oxyde noir, de nickel chimique ou de phosphate, offrant une résistance à l'usure, une protection contre la corrosion et une durée de vie prolongée dans des environnements d'exploitation contaminés ou à forte humidité.

Applications:

Systèmes d'entraînement de la distribution du moteur: Essentiel pour les applications DOHC, de calage variable des soupapes et d'entraînement d'arbre à cames haute performance nécessitant un glissement nul et une corrélation de calage permanente entre le vilebrequin et l'arbre à cames.

Transmission de puissance industrielleIdéal pour les broches de machines-outils, les presses d'imprimerie, les équipements d'emballage et les machines textiles exigeant un mouvement multi-axes synchronisé sans erreur de positionnement cumulative.

Entraînements d'accessoires automobiles: Convient aux entraînements de compresseurs, aux systèmes d'arbres d'équilibrage et aux équipements auxiliaires nécessitant un engagement positif et un fonctionnement sans entretien.

Instrumentation de précisionConçu pour les appareils d'imagerie médicale, les équipements de fabrication de semi-conducteurs et l'automatisation de laboratoire nécessitant un transfert de mouvement rotatif silencieux et sans jeu.

Production de prototypes sur mesure et en petites séries: Permet de répondre aux exigences spécifiques en matière de transmission, de modernisation de moteurs anciens et de construction de machines uniques avec des entraxes et des rapports de transmission non standard.

Bien plus qu'une simple roue dentée, cette poulie de distribution moulée à la cire perdue est le garant de la précision temporelle de votre système rotatif : elle préserve l'angle de phase, élimine les erreurs cumulatives et assure que chaque composant entraîné arrive exactement au bon moment et au bon endroit, conformément aux exigences de votre processus. Que vous conceviez une distribution de compétition ou un système d'indexage industriel de haute précision, cette pièce prouve que la fiabilité du calage repose sur une continuité de denture intégrée et moulée avec précision.