Solutions de fonderie sur mesure pour la fabrication de raccords araignée

S'appuyant sur son expertise en matière de fonderie de précision et de finition CNC, HDC propose des services de fabrication sur mesure aux constructeurs et aux marques qui recherchent des systèmes de fixation d'araignée non standard adaptés à leurs besoins.

Que peut offrir HDC ?

Ébauches de fonderie sur mesure

HDC propose des ébauches de fixations sur mesure, réalisées à partir de votre conception ou échantillon. Seuls les ébavures et le polissage nécessaires sont effectués. Cette solution est idéale pour les fabricants disposant d'un service de finition interne.

Pièces finies avec précision

Outre la fonderie, HDC propose également un service d'usinage CNC pour la finition des bras de fixation d'araignée. Nous pouvons réaliser les trous et surfaces de montage critiques pour adapter vos accessoires existants ou remplacer vos anciens bras de fixation d'araignée.

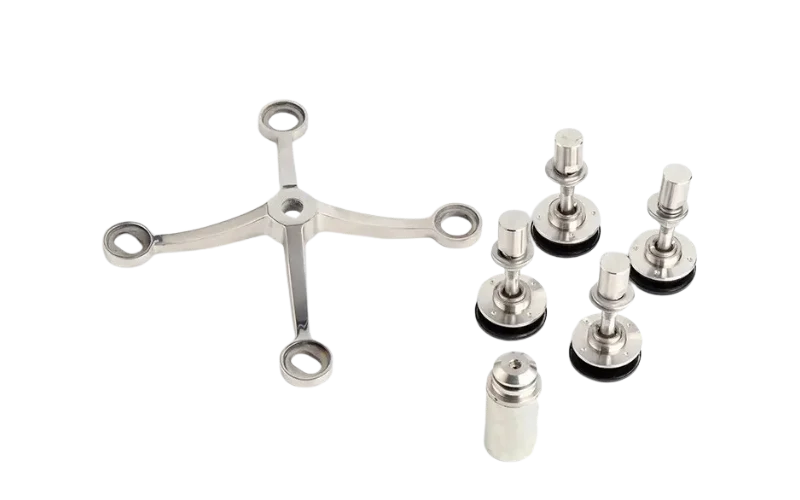

Ensembles entièrement assemblés

Grâce à sa chaîne d'approvisionnement éprouvée, HDC propose des solutions OEM complètes, de la fonderie à l'usinage CNC en passant par la personnalisation des accessoires. Un seul fournisseur suffit pour obtenir des ensembles de fixation sur mesure.

Ajustement type d'araignée que nous pouvons mouler

HDC prend en charge la fabrication de fixations araignées sur mesure, répondant à tous vos besoins en matière de structure, de fonction, de résistance et de matériaux.

Raccord araignée unidirectionnel

Support de vitre à un bras moulé avec précision, conçu pour le maintien du verre en bordure ou en angle. HDC peut le personnaliser avec différentes longueurs pour s'adapter à vos cadres structurels périphériques.

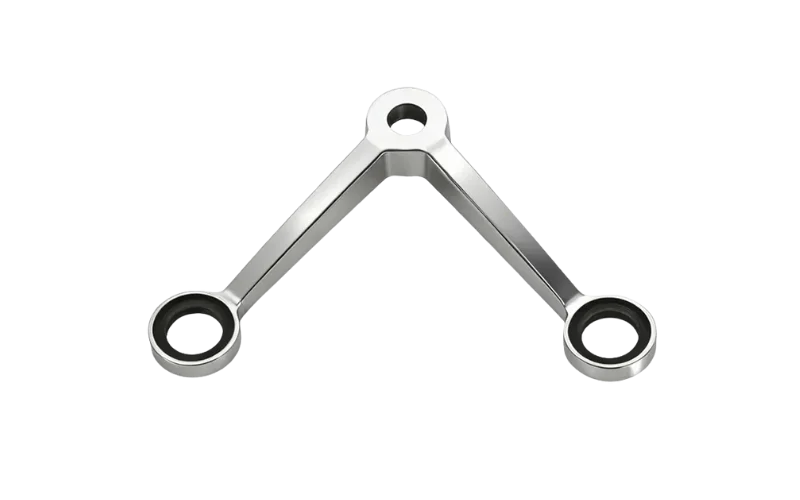

Raccord araignée à 2 voies (90°)

Contrôle précis de l'angle grâce à une conception optimisée du moule en cire et un processus de coulée simplifié. Nous proposons des angles personnalisés de 30° à 180°.

Raccord araignée à 2 voies (180°)

Conçus pour raccorder deux panneaux alignés, ces raccords peuvent être fabriqués sur mesure en acier haute résistance pour supporter des panneaux jusqu'à 50 kg.

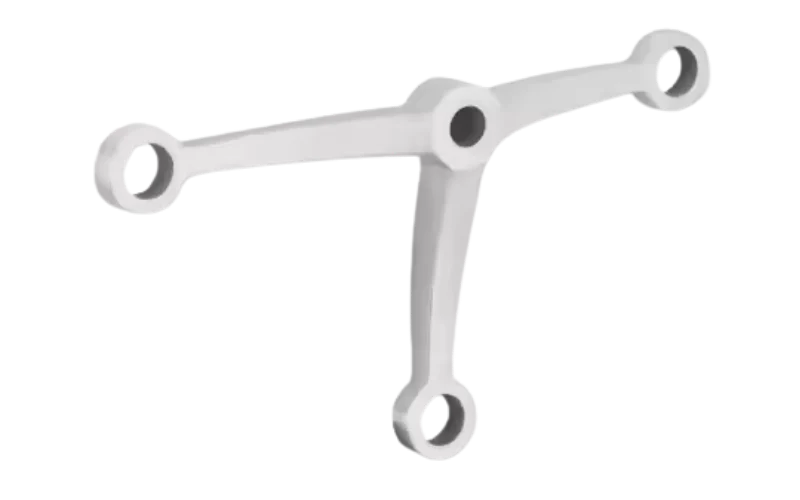

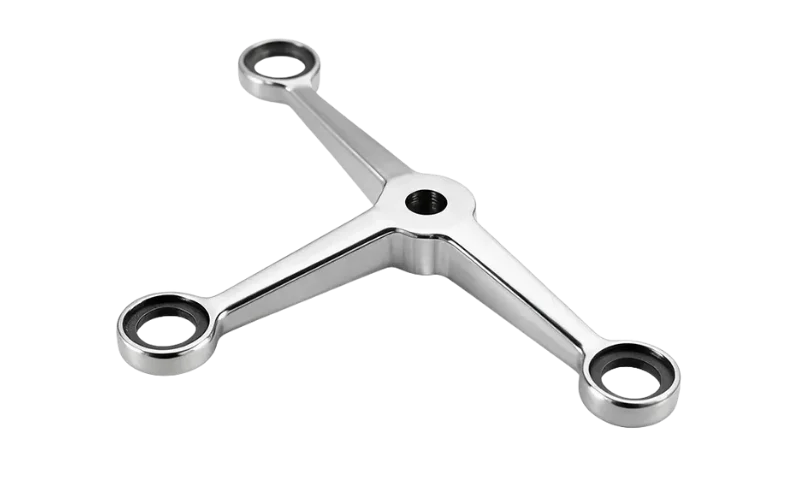

Raccord araignée à 3 voies

Également connus sous le nom de raccords en T, ces composants sont utilisés aux jonctions en T pour supporter des charges structurelles asymétriques.

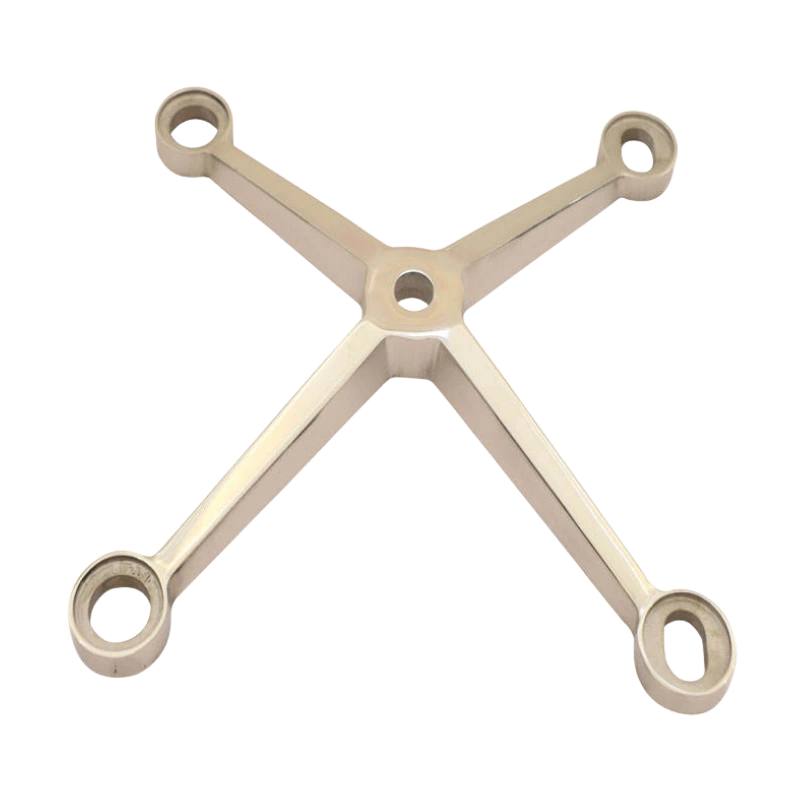

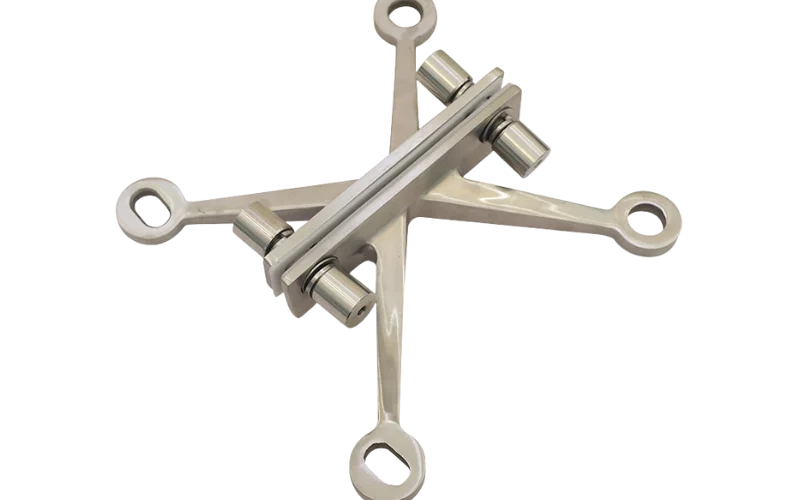

Raccord araignée à 4 voies

Pour connecter efficacement quatre panneaux à un seul nœud, vous avez besoin d'un raccord en forme d'araignée à 4 bras de conception monobloc moulée pour supporter une charge élevée.

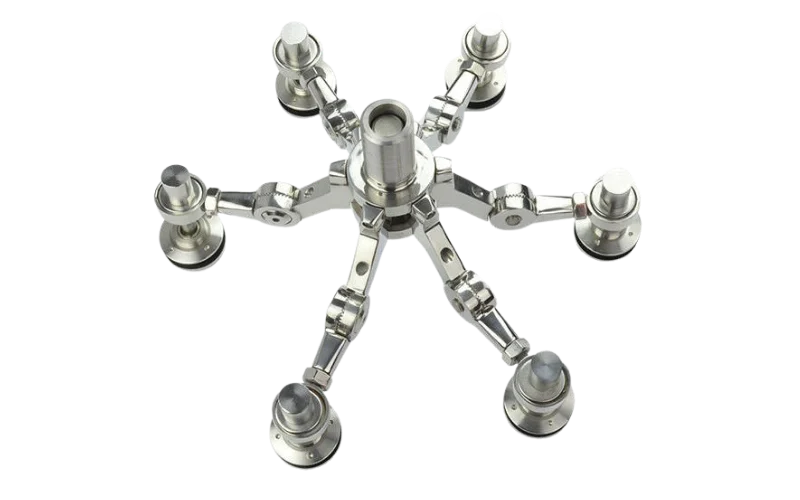

Raccord araignée à 6 voies

Le système de fixation multipoints en forme d'araignée est spécialement conçu pour les assemblages complexes de panneaux tridimensionnels. Chez HDC, nous répondons à tous vos besoins en matière de connexion grâce à nos capacités de moulage sur mesure inégalées.

Raccord araignée de type K

Ce raccord en forme d'araignée doit son nom à sa géométrie caractéristique en “ K ”. Il est souvent utilisé avec des systèmes à montage sur ailettes ou sur poteaux pour une esthétique moderne et industrielle.

Raccord d'araignée à montage d'aileron

Afin de réduire l'utilisation de colonnes métalliques et d'optimiser l'esthétique de la façade vitrée, HDC propose des services de fabrication sur mesure pour ces composants spécifiques.

Pourquoi le moulage de précision pour les raccords Spider ?

Notre expertise en matière de fonderie de précision nous permet de produire des raccords sur mesure adaptés à votre projet.

Géométrie complexe et liberté de conception

Le moulage à la cire perdue est reconnu pour sa capacité à produire des pièces métalliques aux formes complexes. Qu'il s'agisse d'esthétique ou de fonctionnalité, HDC concrétisera votre projet de fixation unique.

Finition de surface et précision supérieures

Nous utilisons des moules en céramique de haute qualité pour obtenir une finition lisse dès le démoulage. Cela minimise le polissage secondaire et garantit une esthétique irréprochable pour chaque élément de votre façade vitrée.

Polyvalence des matériaux haute performance

Vous pouvez fabriquer des raccords en forme d'araignée avec presque tous les types d'acier inoxydable et d'acier allié par moulage de précision, tels que SS316 et Duplex 2205, pour des applications spécifiques.

Rentable en production de masse

Grâce à la capacité de production de pièces quasi-finies du moulage à la cire perdue, seul un usinage CNC minimal est nécessaire pour atteindre la tolérance souhaitée pour le montage en étoile.

Capacités de base HDC

Comment HDC garantit-elle une qualité constante, du moulage au produit final ? Voici les réponses.

Support technique

Nous fournissons un soutien professionnel en matière de conception pour la fabrication (DFM) afin d'optimiser votre conception et d'obtenir de meilleures performances structurelles et une rentabilité accrue, sans compromettre votre vision architecturale.

Solution unique

En combinant notre procédé de fonderie de précision interne avec l'usinage CNC, nous offrons un flux de production sans faille, des matières premières au produit final.

Contrôle de qualité

Nous sommes pleinement conscients que la sécurité est primordiale pour les ferrures de façade en verre. C'est pourquoi nous mettons en place un contrôle qualité rigoureux afin de garantir que chaque composant réponde aux normes de sécurité.

Matériaux pour le moulage de raccords araignée

L'acier inoxydable est privilégié pour les composants des systèmes de façades rideaux en verre, principalement en raison de ses deux atouts : un aspect moderne et brillant et une excellente résistance à la corrosion. Il est choisi pour son intégration harmonieuse aux bâtiments à structure de verre et de métal, et pour sa capacité à résister aux environnements extérieurs rigoureux.

Les qualités courantes que nous proposons comprennent 304, 316L et 2205.

L'acier au carbone est privilégié pour sa haute résistance et son faible coût par rapport à la plupart des aciers inoxydables. Cependant, des traitements de surface spécifiques sont nécessaires pour résister aux conditions extérieures.

Nous proposons une large gamme d'acier au carbone, notamment 1025 et 1045.

Finitions de surface disponibles

Grâce à ses capacités de finition internes et à ses partenaires de longue date, HDC propose ci-dessous les options de traitement de surface pour vos fixations araignées sur mesure. D'autres options sont disponibles sur demande.

| 🔷 Brossé | 🔷 Polissage miroir |

| 🔷 Électropolissage | 🔷 Passivation |

| 🔷 Revêtement en poudre | 🔷 Sablage / Microbillage |

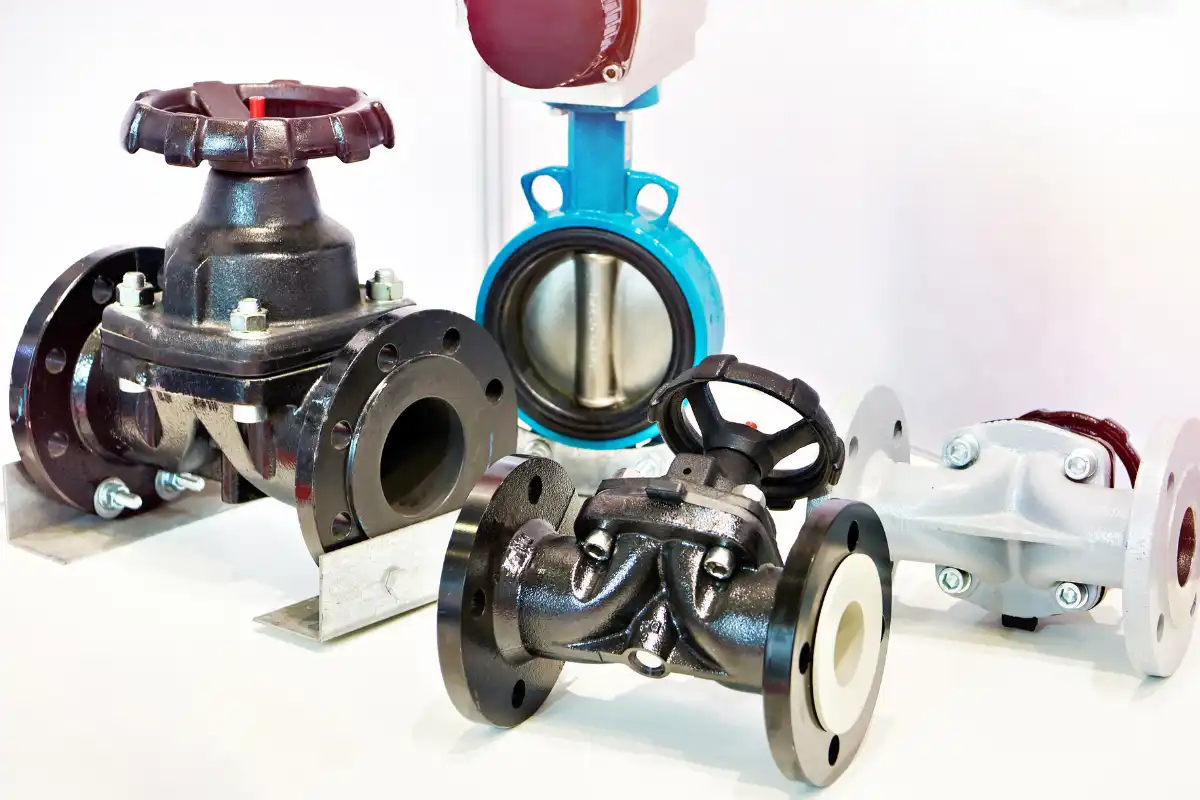

Applications typiques des raccords Spider

Les fixations en forme d'araignée moulées avec précision de HDC sont conçues pour supporter les structures en verre haute transparence où la résistance structurelle et l'élégance esthétique sont tout aussi essentielles. Voici quelques exemples d'applications que nous prenons en charge :

| 🔷 Murs-rideaux en verre à fixation ponctuelle | 🔷 Systèmes de balustrades et de garde-corps en verre |

| 🔷 Ponts et planchers en verre structurel | 🔷 Passerelles vitrées et plateformes d'observation |

| 🔷 Auvents et systèmes d'entrée en verre | 🔷 Cloisons et vitrines intérieures en verre |

Démarrez votre projet personnalisé dès aujourd'hui

Vous recherchez un partenaire de fabrication fiable pour votre prochaine façade en verre ? Contactez-nous pour obtenir un devis gratuit et une analyse de faisabilité technique sous 24 heures.

FAQ

Qu'est-ce qu'un raccord araignée ?

Un système de fixation en araignée est un composant de fixation de verre à support ponctuel couramment utilisé dans les systèmes de vitrage architecturaux modernes.

Il permet de fixer des panneaux de verre à une structure porteuse tout en préservant la transparence et la stabilité structurelle.

Quels sont les principaux composants d'un système de fixation en araignée ?

Un système de fixation araignée typique se compose de :

- Bras d'araignée (à un, deux ou plusieurs bras)

- Rotules ou boulons

- Connecteurs en verre et matériel de montage

Chaque composant fonctionne en synergie pour transférer les charges en toute sécurité à la structure porteuse.

De quels matériaux sont généralement faits les raccords en forme d'araignée ?

Les raccords araignées sont le plus souvent fabriqués à partir de acier inoxydable, comme l'acier inoxydable SS304 ou SS316.

Ces matériaux offrent une excellente résistance, une bonne résistance à la corrosion et une grande durabilité, aussi bien pour les applications intérieures qu'extérieures.

Quels types de fixations pour araignées sont disponibles ?

Les fixations à araignée sont généralement classées selon le nombre de bras, les types les plus courants étant :

- Fixations d'araignée à un seul bras

- Fixations d'araignée à deux bras

- Fixations en forme d'araignée à quatre bras

Le choix dépend de la disposition des vitrages, des exigences de charge et de la conception architecturale.

Comment installe-t-on les raccords en araignée ?

Les fixations en araignée sont montées sur une structure de support telle que des poutres en acier, du béton ou des ailettes en verre.

Les panneaux de verre sont ensuite reliés par des rotules, permettant un mouvement contrôlé pour compenser la dilatation thermique et la déformation structurelle.

Les fixations en araignée peuvent-elles être personnalisées pour différents projets ?

Oui. Les fixations en araignée peuvent être personnalisées en termes de dimensions, de configuration des bras, de qualité des matériaux et de finition de surface afin de répondre aux exigences spécifiques du projet et aux normes de conception.

Quelle est la différence entre les fixations araignées et les systèmes de vitrage encadrés ?

Contrairement aux systèmes à cadre, les fixations en araignée utilisent des connexions ponctuelles au lieu de cadres continus.

Il en résulte une plus grande transparence, une apparence visuelle plus légère et une plus grande flexibilité de conception.