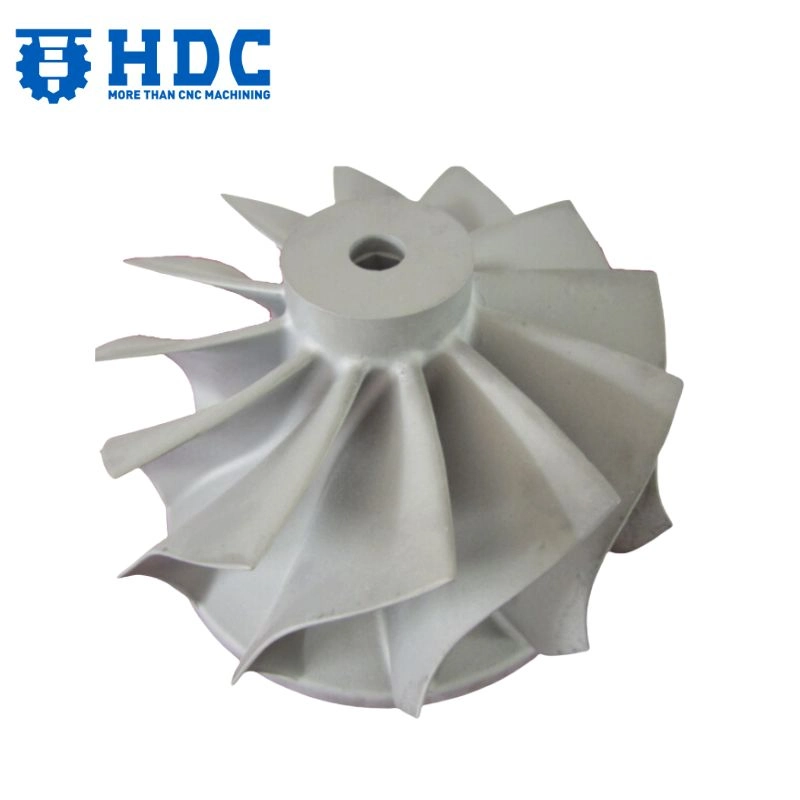

Turbine de pompe à eau en acier/aluminium/superalliage/laiton, pièce moulée sur mesure

Détails du produit personnalisé

| Numéro de modèle. | HDCIPI001 |

| Style | Roue de pompe moulée à la cire perdue |

| Matériel | Aluminium, alliage d'aluminium, acier inoxydable, alliage d'acier, superalliage, laiton |

| Type de finition | Brut, poli, anodisé, revêtu par électrophorèse, revêtu de poudre, galvanisé, chromé, oxydé noir |

| Taille disponible | / |

| MOQ | 50 pièces |

| Logo personnalisé | Disponible |

| Origine | Chine |

| Emballage et livraison | |

| Option d'expédition | Courrier, air, mer, chemin de fer express, EXW, FOB, CIF, DDU, DDP |

| La date de livraison | 25-30 jours |

| Forfait Transport | Personnalisé, Carton, Palette |

Optimisez le transfert de fluides grâce à cette roue de pompe à eau moulée sur mesure. Conçue avec précision pour la gestion thermique, la circulation et les systèmes de pompage industriels, cette pièce offre des performances hydrauliques constantes grâce à une géométrie de pale moulée d'une seule pièce, alliant la flexibilité du matériau et la continuité du flux optimisé que seul le moulage à la cire perdue peut garantir.

Polyvalence des matériaux multi-alliagesDisponible en acier haute résistance, en aluminium léger, en superalliage avancé ou en laiton résistant à la corrosion – chaque matériau étant sélectionné avec précision pour correspondre à des températures de fluides, des pressions nominales, une compatibilité chimique et des objectifs de réduction de poids spécifiques.

Géométrie complexe des pales moulées par investissementLe moulage de précision à la cire perdue permet la formation d'ailettes aux contours complexes, de profils d'épaisseur variable et de bords d'attaque/de fuite fondus, impossibles à obtenir par usinage conventionnel ou par assemblages fabriqués, préservant ainsi l'intention aérodynamique/hydraulique sans compromis.

Intégrité structurelle monoblocLa construction monobloc moulée élimine les joints soudés, les coutures brasées et les fixations mécaniques, supprimant ainsi les points de défaillance potentiels tout en maintenant des propriétés de matériau continues de l'œil au carénage.

Passages à flux lisse et sans restrictionLes finitions de surface moulées et la géométrie optimisée des canaux entre les aubes minimisent les pertes par frottement, réduisent le potentiel de cavitation et maintiennent des caractéristiques d'écoulement laminaire sur toute la plage de fonctionnement.

Excellent équilibre dynamiqueLa précision de moulage quasi-définitive associée à un équilibrage CNC de précision garantit une rotation concentrique, un pas d'ailette constant et des vibrations minimales, prolongeant ainsi la durée de vie des joints et réduisant l'usure des roulements dans les applications à service continu.

Profil hydraulique entièrement personnalisableFabriqués selon les spécifications du client en matière de nombre d'ailettes, de diamètres de sortie, de configurations de moyeu et de débit, ils répondent à tous les besoins, du refroidissement automobile à grand volume à la circulation de processus industriels lourds.

Ingénierie de surface optimisée pour l'applicationDisponible avec des revêtements céramiques en option, des revêtements résistants à l'érosion ou des traitements de passivation chimique, offrant une protection durable contre les particules abrasives, les dommages causés par la cavitation et les fluides agressifs.

Applications:

Refroidissement des moteurs automobiles: Idéal pour les pompes à eau, la circulation électrique auxiliaire et les systèmes de gestion thermique hybrides nécessitant un format compact et un débit constant.

Circulation des procédés industriels: Essentiel pour les tours de refroidissement, les refroidisseurs CVC, les systèmes d'alimentation de chaudières et les applications de transfert de produits chimiques exigeant une résistance à la corrosion et une efficacité hydraulique vérifiées.

Pompage marin et offshore: Convient aux systèmes de refroidissement à l'eau brute des moteurs, de transfert de ballast et de lavage des ponts nécessitant une compatibilité galvanique et une résistance à l'eau salée.

Irrigation et transfert agricolesConçu pour les systèmes d'irrigation à pivot central, l'abreuvement du bétail et les équipements de pulvérisation des cultures nécessitant une résistance à l'abrasion dans les fluides chargés de particules.

Systèmes de gestion des fluides personnalisésIdéal pour le développement de prototypes, la construction de véhicules spéciaux et les applications industrielles uniques nécessitant une géométrie de turbine non standard avec une caractérisation de flux certifiée.

Bien plus qu'un simple élément rotatif, cette roue moulée à la cire perdue est le véritable maître d'œuvre hydraulique de votre système de fluides : elle transforme l'énergie de rotation en un débit précisément dosé à chaque tour, saison après saison. Que vous conceviez l'architecture thermique des véhicules électriques de nouvelle génération ou les infrastructures industrielles lourdes de protection contre les inondations, ce composant prouve que l'efficacité du pompage repose sur une conception monobloc moulée avec précision.