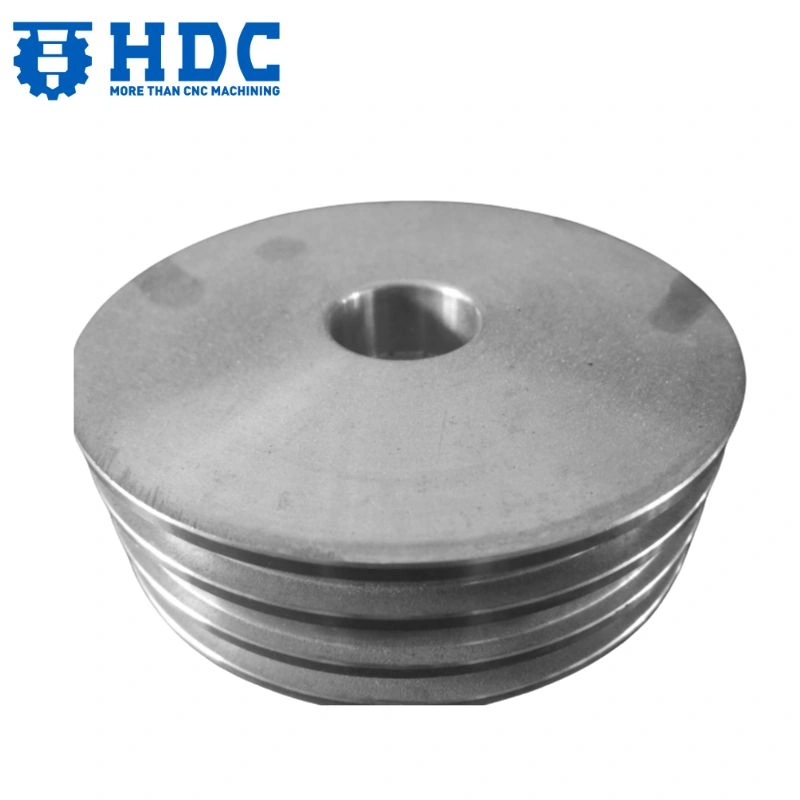

Tête de transducteur ultrasonique pour fonderie de précision, transducteur de vibrations, tamis à vibrations ultrasoniques

Détails du produit personnalisé

| Numéro de modèle. | HDCIUT001 |

| Style | Transducteur ultrasonique pour moulage de précision |

| Matériel | Aluminium, alliage d'aluminium, acier, alliage d'acier, superalliage, laiton |

| Type de finition | Brut, poli, anodisé, revêtu par électrophorèse, revêtu de poudre, galvanisé, chromé, oxydé noir |

| Taille disponible | / |

| MOQ | 50 pièces |

| Logo personnalisé | Disponible |

| Origine | Chine |

| Emballage et livraison | |

| Option d'expédition | Courrier, air, mer, chemin de fer express, EXW, FOB, CIF, DDU, DDP |

| La date de livraison | 25-30 jours |

| Forfait Transport | Personnalisé, Carton, Palette |

Attain resonant precision and structural endurance with this investment-cast ultrasonic transducer head—precision-engineered for high-frequency vibration applications demanding uncompromised energy transmission, environmental isolation, and mechanical longevity. At the intersection of metallurgical integrity and acoustic physics, this component converts electrical excitation into controlled mechanical displacement with crystalline fidelity.

Premium Material Selection: Precision investment-cast in 316L stainless steel for universal chemical resistance and hygienic compliance, or in advanced high-performance alloys for extended amplitude operation and aggressive media compatibility—each alloy system calibrated to specific frequency ranges, power densities, and thermal loads.

Monolithic, Void-Free Architecture: Single-piece investment casting eliminates welded joints, brazed interfaces, and mechanical clamping—removing energy-dissipative boundaries while ensuring continuous acoustic impedance matching from piezoelectric stack to radiating surface.

Hermetic Sealing Integrity: Continuously cast grain structure combined with precision-machined sealing interfaces delivers verified IP69K ingress protection, safeguarding sensitive piezoelectric ceramics against fine particulate infiltration, high-pressure washdown, and condensate ingress during continuous-duty operation.

Integrated Thermal Management: Cast-in heat-dissipating geometry and thermally optimized alloy selection actively conduct waste energy away from resonant stacks, preserving frequency stability and amplitude consistency throughout extended production cycles.

Fatigue-Engineered Resonant Structure: Homogeneous, porosity-free material architecture with stress-optimized internal radii delivers verified fatigue life through billions of expansion/contraction cycles at ultrasonic frequencies—essential for 24/7 industrial screening, cleaning, and machining environments.

Precision-Finished Acoustic Interfaces: CNC-machined front mass radiating surfaces and rear mass mounting interfaces are held to micron-level flatness and surface finish specifications, ensuring optimal energy transfer to booster assemblies, horn adapters, or integrally coupled sieve frames.

Application-Tuned Customization: Manufactured to customer-specific resonant frequency tuning, bolt circle patterns, flange geometries, and integrated cooling or sensor provisions—accommodating laboratory-scale 35kHz analytical sieves through high-amplitude 20kHz industrial processing systems.

Applications:

Ultrasonic Vibrating Screens: Delivers continuous anti-blinding performance for fine powders (20–500µm), metal alloys, battery materials, pharmaceutical granules, and food ingredients requiring narrow particle size distribution and contamination-free operation.

Ultrasonic Cleaning Systems: Provides uniform cavitation energy for precision component degreasing, semiconductor wafer processing, and medical device sterilization requiring aggressive chemistry compatibility and validated cleanliness levels.

Rotary Ultrasonic Machining: Enables precision drilling of ceramics, glass, and composite materials requiring sustained amplitude delivery under continuous cutting loads with minimal tool pressure.

Plastic & Metal Welding Systems: Engineered for high-duty-cycle thermoplastic joining and light-gauge metal spot welding demanding resonant stability and rapid amplitude recovery between successive weld events.

More than an electromechanical converter, this investment-cast transducer head is the resonant conscience of your ultrasonic system—translating sinusoidal excitation into precisely metered mechanical displacement, preserving phase coherence across every operating cycle, and ensuring your process outcomes remain faithful to applied frequency and amplitude setpoints. Whether classifying battery-grade cathode materials under strict ISO cleanroom protocols or welding automotive components at rate, it’s the component that proves ultrasonic precision begins with precision-cast, monolithically resonant continuity.