OEM Forging Brake Lever Manufacturer

HDC offers custom forging brake lever services for any handlebar-controlled vehicle, including bikes, motorcycles, scooters, and more.

Brake Lever by Applications

Need an OEM replacement or a custom, unique design brake lever for your brand? HDC got all the vehicle types covered.

Bike Brake Lever

By forging and CNC finishing, HDC produces brake levers with optimized operation experience and perfect fitment for road bikes, mountain bikes, and more.

BMX Brake Lever

To achieve precise control in intensive riding, HDC forges brake levers for BMX bikes with high-strength aluminum and CNC-machined for a complex ergonomic structure.

Levier de frein de moto

HDC forges brake levers for all the motorcycle brands you can name on the market(Yamaha, Honda, Kawasaki, CFMoto, etc.), whether it’s a forged blank or a fully assembled brake lever.

Electric Bike Brake Lever

The electric bike industry has developed rapidly in recent years. With our flexible forging and machining capabilities, HDC can support your electric bike brand from small to big.

Scooter Brake Lever

Scooters are favored for short-distance transportation. HDC can forge scooter brake levers with aluminum and titanium for weight reduction and improving battery life.

ATV Brake Lever

With the 6061 and aerospace-grade 7075 aluminum we forge, HDC can produce brake levers for ATVs that handle greater braking force in off-road riding.

Brake Lever Types

HDC fabrique une large gamme de boulons à œil disponibles sur le marché et propose également des services sur mesure.

Hand Brake Lever

With rich experience in close die forging and CNC machining, we can manufacture hand brake levers with an intricate ergonomic shape, bringing your design to life and helping your brand stand out from competitors.

Foot Brake Lever

Foot brake levers are used in most rear braking systems on motorcycles and ATVs. We produce it by forging high-quality aluminum alloy to withstand repeated trampling and impact force. An additional anti-slip design is also available.

Adjustable Brake Lever

Adjustable brake levers allow for adjusting the lever travel to adapt to different riders’ habits. The adjustment structure needs precision CNC machining for smooth operation. That’s exactly where HDC’s multi-axis machining center comes into play.

Double Brake Lever

Double brake levers can control two brake cables at the same time, but the structure is more complicated. That’s why we utilize close die forging for near-net shape billet production, which can significantly reduce machining and save cost.

Front Brake Lever

Front brake levers provide most braking force. They are designed for precise and powerful front wheel braking. You can find it on any vehicle with a handlebar control. HDC manufacturer them for bike, motorcycle, scooter, ATV, and more.

Rear Brake Lever

On a motorcycle, the rear brake lever commonly refers to a foot brake lever. While on a scooter or bicycle, it’s usually the brake handle on your left hand. No matter what types you are seeking, HDC is ready to build it for you.

Pourquoi choisir HDC

Why should you trust HDC for a forged brake lever? Here is the answer.

Forgeage à haute résistance

We produce brake levers by close die forging technology with forging press up to 4000T. Which allow us to provide brake levers that are stronger than that CNC maching from billet.

Precision CNC Finishing

HDC not only provides forged brake lever blanks but also offers ready to use final products with our comprehensive CNC finishing capabilities.

Options de personnalisation riches

We offer rich customization options to satisfy your unique aesthetic and enrich your product line, including materials, finishes, colors, and additional features like anti-slip design.

Service complet

We provide support services for brake lever design, material selection, finish options, shipping, and payment terms, making sourcing as convenient as locally.

How HDC Produce Brake Lever

Learn more about HDC’s capabilities in manufacturing brake levers.

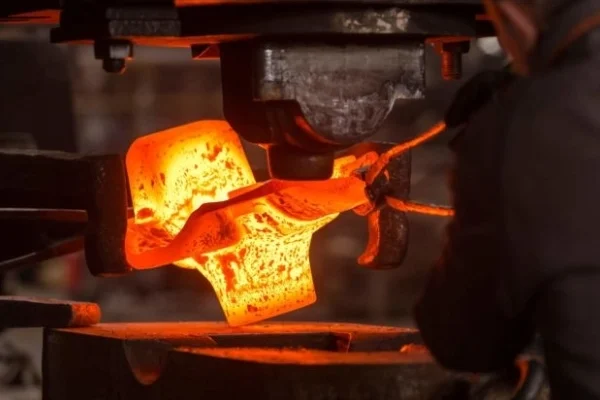

Mold Making and Forging

Firstly, we manufacture molds used in close die forging based on your brake lever drawings or samples. And then forges billets into brake lever blanks. All processes are done with our in-house manufacturer capabilities.

Traitement thermique

After forging and trimming, we’ll apply heat treatment based on the materials used, performance requirements, or specific designs, including solution treatment, aging, etc.

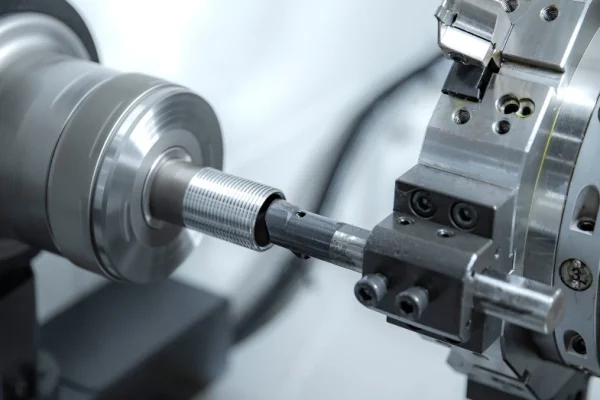

CNC Machining & Surface Treatment

After heat treatment, we apply post-processing with our multi-axis machining center for tight tolerance and specific geometry design. We also provide surface treatment if needed.

Consultez notre contrôle de qualité méthodes de forgeage de pièces.

Brake Lever Materials

Our commitment to quality begins with the high-quality materials we use.

Aluminum alloy is considered to be the best material for brake levers. Since it balances strength, weight, and cost. Additionally, it can be easily formed into complex brake lever geometries with forging, especially suitable for mass production. Moreover, the surface treatment for aluminum is mature and diverse, you can customize aluminum brake lever into any surface desired.

The aluminum alloy grades that HDC provides for custom brake levers include 6061 et 7075.

Stainless steel is not a regular material for a brake lever. But it’s valued for its shiny appearance and corrosion resistance property in some specific types of motorcycles, such as classic & vintage motorcycles, custom choppers, and cruisers etc.

HDC can forge stainless steel brake lever for you with 304 et 316.

Brake Lever Finishes

HDC can provide any surface treatment you require with our powerful supply chain.

Anodizing is the most common surface finish for brake levers that are made of aluminum. At HDC, we offer clear anodizing, colorful anodizing, and hard anodizing(Type III) for enhanced appearance and properties.

Spécifications techniques

Get to know the range of HDC’s custom forging brake lever capabilities.

| Product Type | Hand brake lever, foot brake lever, adjustable brake lever, double brake lever |

| Applicable Vehicles | Bicycle, BMX, motorcycle, ATV, scooter, UTV |

| Manufacturing Process | Closed-die forging + CNC machining |

| Forging Material Options | Aluminum alloys (6061, 7075), 304, 316 |

| Part Weight Range | 50 g – 1.5 kg |

| Longueur totale maximale | Up to 320 mm |

| Tolérance dimensionnelle | ±0.05 mm (critical pivot and mounting areas) |

| Rugosité de surface | Ra ≤ 1.6 μm (machined functional surfaces) |

| Brake System Compatibility | Cable brake and hydraulic brake systems |

| Traitement thermique | T6 heat treatment for aluminum, quenching & tempering for steel |

| Traitement de surface | Anodizing, hard anodizing |

| Logo & Branding | Laser marking, CNC engraving |

| Tooling Development | In-house die design and forging tooling |

| Prototype Capability | Rapid prototyping available before mass production |

| MOQ | Based on part complexity and material |

| OEM / ODM Support | Full OEM customization support |

Need Custom Build Brake Levers?

Contactez HDC et bénéficiez de la solution complète et experte en matière de produits de forgeage. Envoyez-nous simplement un e-mail, notre devis est gratuit !

FAQ

What is a brake lever?

A brake lever is a control component mounted on the handlebar or foot pedal that activates the braking system. When pressed, it applies force to a cable or hydraulic system, slowing or stopping the vehicle by engaging the brake mechanism.

What material are brake levers made of?

Brake levers are commonly made from:

- Aluminum alloys (6061 / 7075) – lightweight, corrosion-resistant, widely used

- Steel – higher strength and durability, used for heavy-duty or off-road applications

High-performance brake levers are often forged and CNC-finished to improve strength and fatigue resistance.

How to fix a loose brake lever?

A loose brake lever is usually caused by improper clamping or worn pivot components. Typical steps include:

- Tightening the handlebar clamp bolts to the specified torque

- Checking the pivot bolt or bushing for wear

- Ensuring the lever housing is correctly seated on the handlebar

If excessive play remains, the lever or internal components may need replacement.

Are all brake levers universal?

No. Brake levers are not universal. Compatibility depends on:

- Brake system type (cable vs. hydraulic)

- Vehicle type (bicycle, motorcycle, ATV, etc.)

- Lever pull ratio and mounting diameter

Using an incompatible brake lever can result in poor braking performance or safety risks.

What are the different types of bike brakes levers?

Common bike brake lever types include:

- Standard (non-adjustable) levers

- Adjustable brake levers (reach or position adjustment)

- Double brake levers (one lever controls two brakes)

- BMX brake levers (short pull, one-finger control)

- E-bike brake levers (with motor cut-off switch)

Each type is designed for specific riding styles and brake systems.

Is the front brake lever on a motorcycle left or right?

On most motorcycles:

- Right hand lever → Front brake

- Right foot pedal → Rear brake

However, configurations may vary by region or for special applications such as racing or left-hand rear brake (LHRB) setups.

Do brake levers make a difference?

Yes. Brake levers directly affect:

- Braking force and modulation

- Rider comfort and fatigue

- Control precision and response time

Lever geometry, material, and manufacturing quality all influence overall braking performance and safety.

What angle should brake levers be?

Brake levers are typically set so the rider’s wrist, forearm, and fingers form a straight or slightly downward line when riding.

For most applications, this results in an angle of approximately 30–45° downward from horizontal, depending on riding position.

How to adjust brake lever angle?

To adjust the brake lever angle:

- Loosen the clamp bolts on the handlebar

- Rotate the lever to the desired position

- Align it for natural wrist and finger movement

- Retighten bolts to the recommended torque

Proper adjustment improves comfort, control, and reaction speed during braking.

Produits connexes