Produzione di parti metalliche personalizzate in un unico punto in Cina

Semplifica la tua catena di fornitura con processi di produzione integrati, tra cui lavorazione CNC, fusione, forgiatura e altro ancora.

🛡️ Tutti i contenuti caricati sono mantenuti sicuri e riservati.

Capacità principali

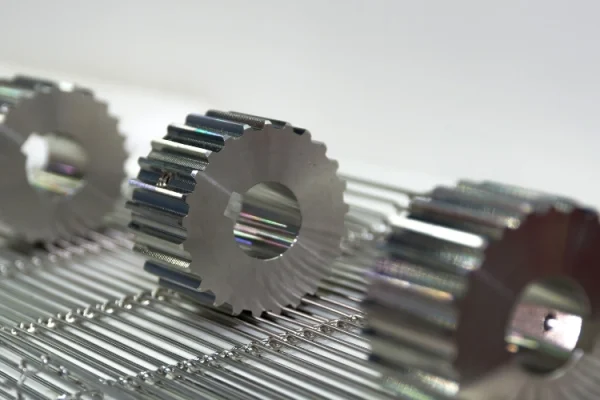

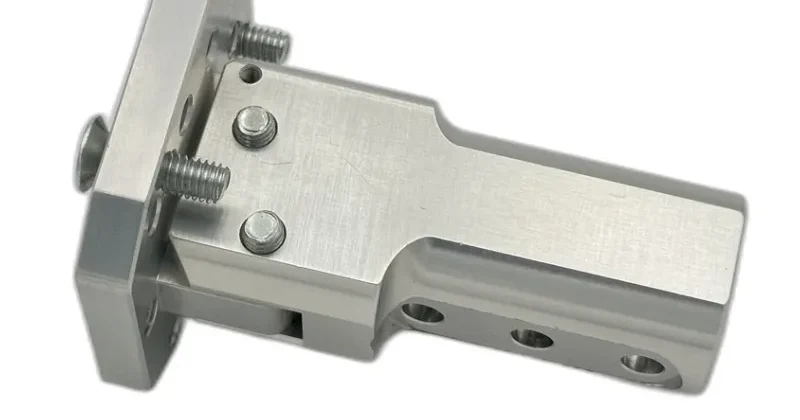

Lavorazione CNC

- Dotato di 3 assi, 4 assi, e 5 assi Centri di lavorazione CNC.

- Tolleranza stretta fino a ±0,005 mm.

- Dimensioni critiche di finitura CNC per fusioni e forgiature.

- Controllo delle dimensioni critiche.

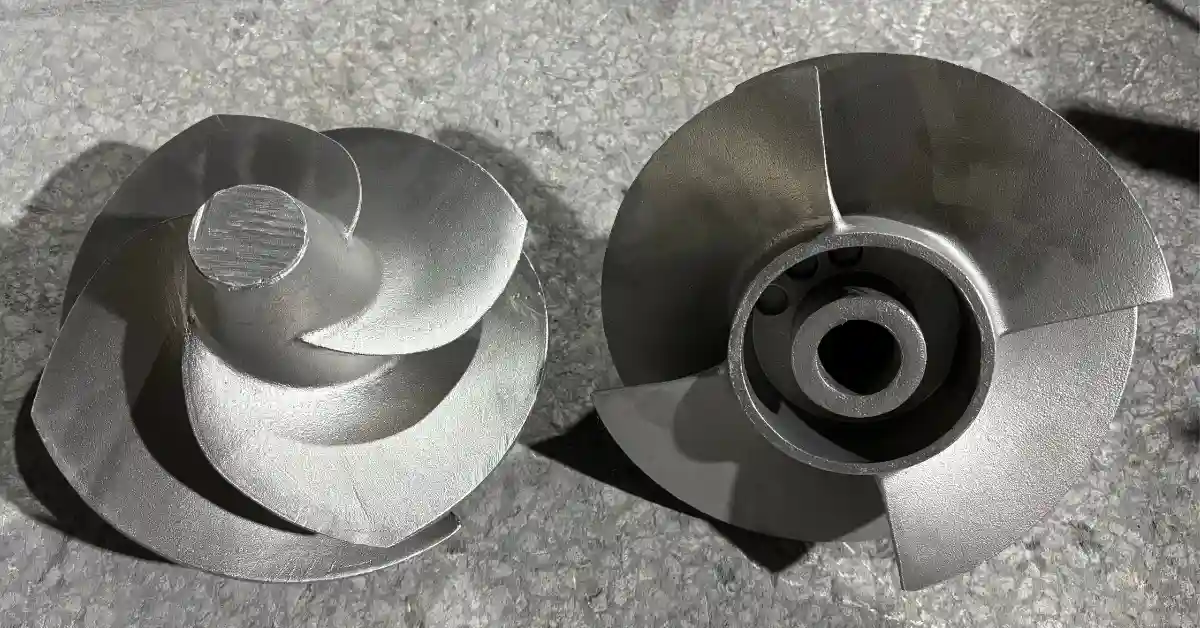

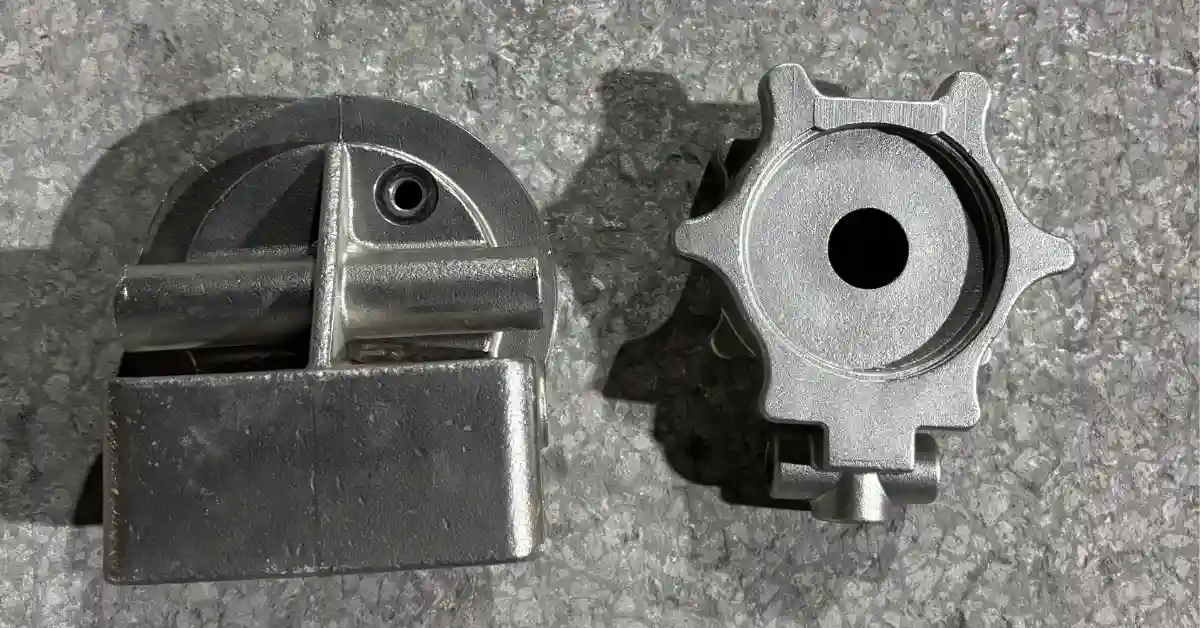

Colata

- Fusione di precisione con acciaio inossidabile, lega di nichel, e altro ancora.

- 50 chili numero massimo di getti singoli.

- Tolleranza stretta con finitura CNC.

- Soluzione personalizzata in processi di fusione, configurazione del materiale, e trattamento termico.

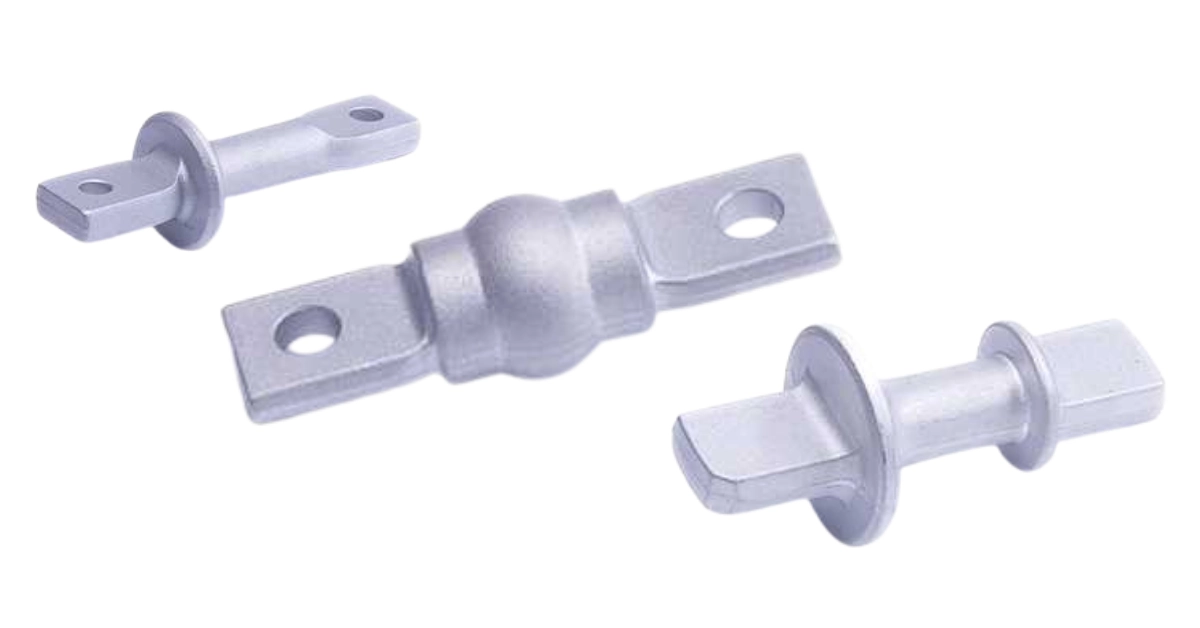

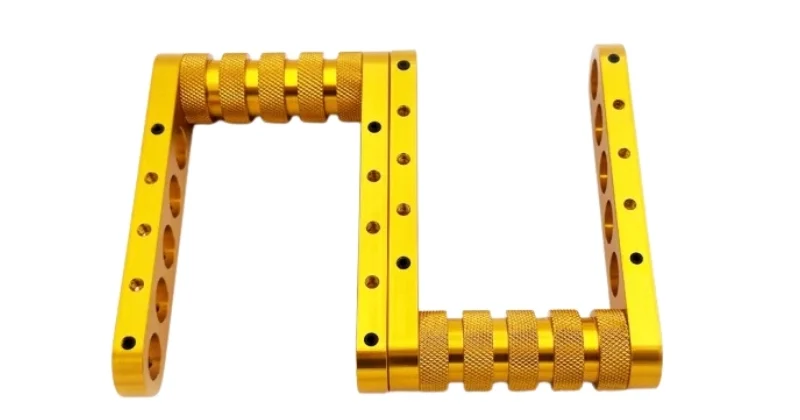

Forgiatura

- Forgiatura con lega di alluminio, acciaio al carbonio, e acciaio inossidabile.

- 30 chili massima forgiatura singola.

- 160T ~ 4000T presse per forgiatura e presse a vite.

- Sono disponibili sia la forgiatura a freddo che quella a caldo.

Servizio globale

Abbiamo servito oltre 1000 clienti provenienti da più di 50 paesi.

Certificato ISO e IATF

Abbiamo la certificazione ISO9001:2005.

Oltre 50 materiali certificati

Possiamo personalizzare le tue parti metalliche con oltre 50 tipi di materiali diversi

Consegna in tempo

Le parti ti verranno consegnate come promesso, da 1 settimana a 30 giorni.

Per maggiori informazioni, visita il nostro Politica di servizio pagina.

Perché scegliere HDC Manufacturing

Più di un produttore: il tuo partner per l'ingegneria e la catena di fornitura

Un progetto reale può essere complesso e richiedere la combinazione di più processi produttivi per realizzare i componenti desiderati. Per i produttori di marchi, gestire più fornitori attraverso processi diversi può rapidamente diventare complesso e rischioso.

Nati come officina CNC, abbiamo continuato ad arricchire le nostre capacità di produzione e sviluppo della nostra catena di fornitura, con l'obiettivo di fornire ai nostri clienti una soluzione completa.

Grazie ai nostri punti di forza nella lavorazione CNC, riuniamo le migliori risorse produttive cinesi nei settori della fusione e della forgiatura in un unico e affidabile sistema di qualità. Dall'ingegneria e dall'approvvigionamento al controllo qualità e alla logistica, gestiamo ogni complessità, così puoi concentrarti sul tuo prodotto, non sui tuoi fornitori.

Valorizza il tuo marchio con soluzioni personalizzate

In HDC Manufacturing, andiamo oltre la produzione. Lavoriamo come un partner pratico e concreto per aiutarti a trasformare le tue idee di prodotto in produzione. Dai concept iniziali ai componenti finiti, supportiamo la produzione di componenti metallici personalizzati e lavorazioni meccaniche di precisione per marchi affermati e in crescita.

Grazie alla lavorazione CNC integrata, alla fusione e alla forgiatura, ti aiutiamo a muoverti più velocemente, a ridurre la complessità della catena di fornitura e a ottenere una qualità costante, così puoi concentrarti sulla costruzione del tuo marchio, non sulla gestione dei fornitori.

Processo di ordinazione

Consulenza iniziale

Condividi i requisiti del tuo progetto con il nostro team. Esamineremo la tua candidatura e ti forniremo suggerimenti pratici di ingegneria per aiutarti a iniziare.

Presentazione del progetto

Inviateci i vostri file di progettazione o collaborate con i nostri ingegneri per perfezionare il progetto in termini di producibilità ed efficienza dei costi.

Preventivo e revisione del design

Riceverai un preventivo chiaro e dettagliato insieme a una revisione finale di tutte le specifiche prima di procedere.

Sviluppo del prototipo

Quando necessario, realizziamo prototipi per convalidare il design, la vestibilità e le prestazioni prima della produzione in serie.

Produzione e Controllo Qualità

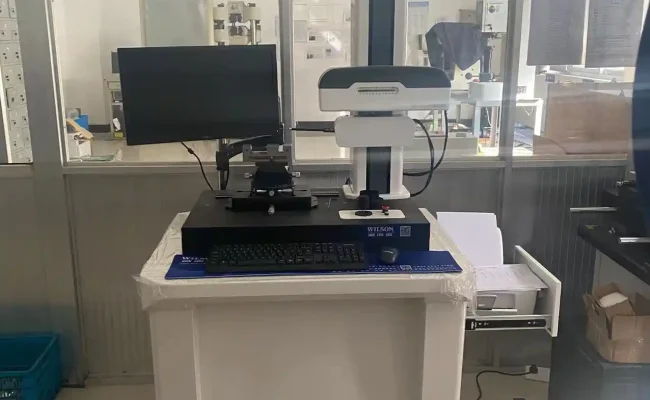

Una volta ottenuta l'approvazione, inizia la produzione su larga scala, supportata da ispezioni in corso d'opera e da rigorosi controlli di qualità in ogni fase.

Spedizione e consegna

Scegli il metodo di spedizione che preferisci. Organizziamo spedizioni in tutto il mondo con tempi di consegna affidabili.

Accedi alle nostre risorse per saperne di più sulle capacità di HDC.

Materiali metallici con cui lavoriamo

HDC Manufacturing lavora con un'ampia gamma di materiali metallici per soddisfare diversi requisiti di resistenza, peso e prestazioni.

Opzioni complete di trattamento superficiale

Grazie alla finitura superficiale interna integrata e a una catena di fornitura post-trattamento affidabile, HDC Manufacturing offre una gamma completa di trattamenti superficiali per migliorare l'aspetto, la durata e le prestazioni funzionali delle parti metalliche personalizzate.

| 🔷 Sabbiatura | 🔷 Pallinatura |

| 🔷 Anodizzazione di tipo Ⅱ | 🔷 Anodizzazione di tipo Ⅲ |

| 🔷 Rivestimento in polvere | 🔷 Pittura |

| 🔷 Zincatura | 🔷 Cromatura |

| 🔷 Incisione laser | 🔷 Ossido nero |

Trattamento termico per parti metalliche

Il trattamento termico svolge un ruolo fondamentale nel raggiungimento della resistenza, durezza e durevolezza richieste alle parti metalliche.

Grazie a processi di trattamento termico controllati e a una catena di fornitura post-trattamento affidabile, supportiamo una gamma completa di opzioni di trattamento termico per ottimizzare le proprietà dei materiali per diverse applicazioni.

| 🔷 Tempra | 🔷Temperatura |

| 🔷 Ricottura | 🔷Normalizzazione |

| 🔷 Trattamento della soluzione |

Controllo di qualità

Prodotti realizzati su misura

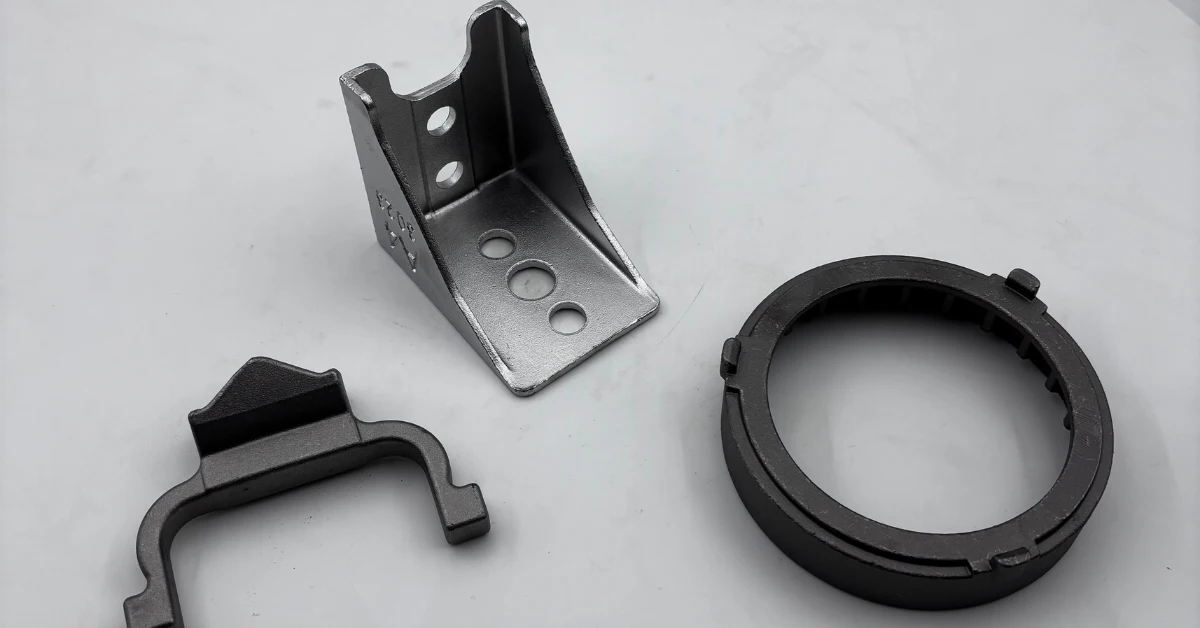

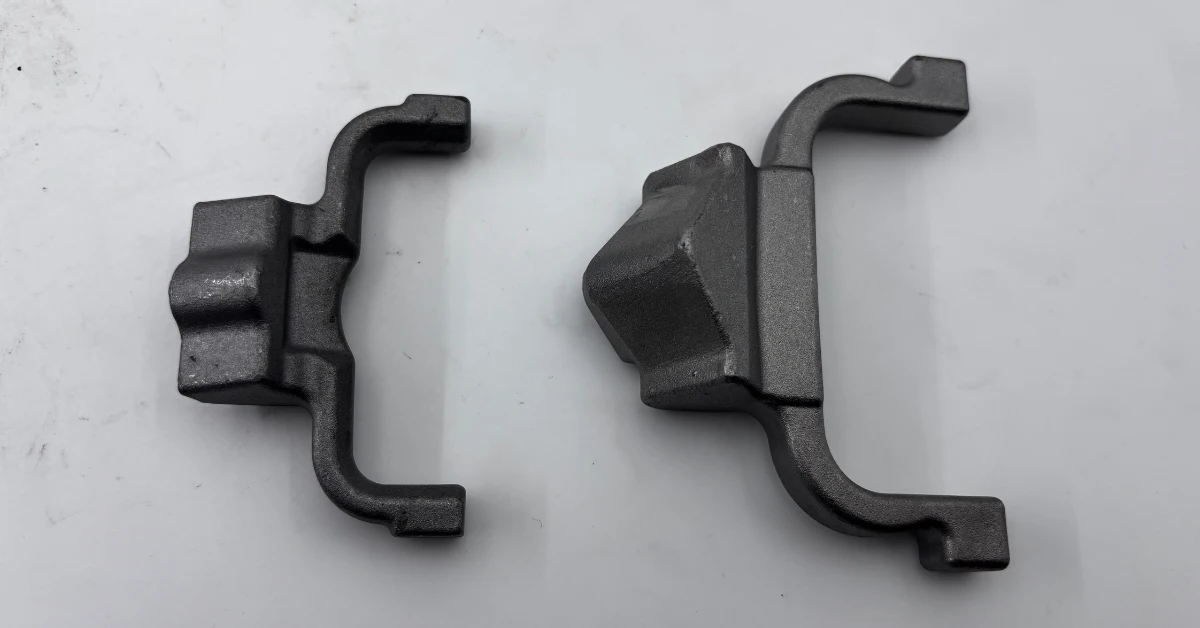

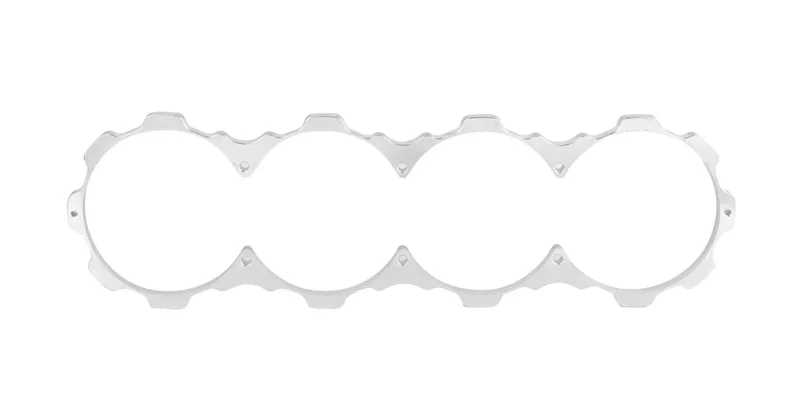

Componenti forgiati, fusi e lavorati a CNC per molteplici settori

Componenti forgiati per autoveicoli

Componenti forgiati per motociclette

Accessori per volante e sterzo

Componenti strutturali e utensili forgiati

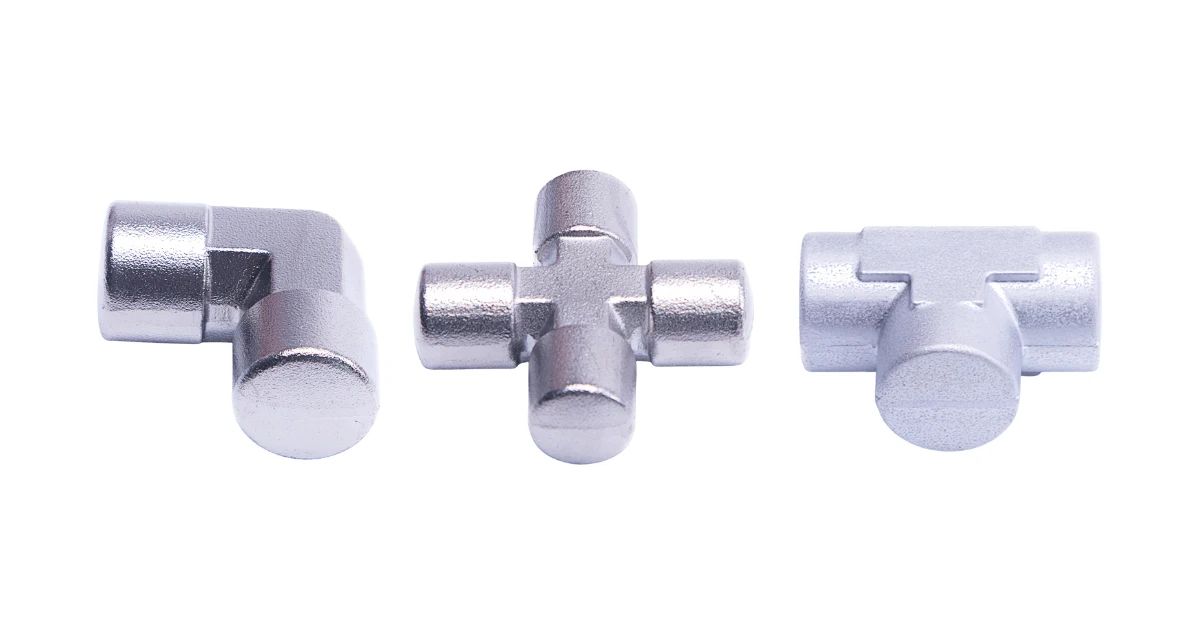

Strumenti, staffe e raccordi

Componenti di fusione industriale

Corpo pompa, valvola, alloggiamento ingranaggi

Parti di fusione del veicolo

Ricambi per auto, moto, biciclette, bici elettriche

Ferramenta e getti strutturali

Connettori, staffe e hardware personalizzato

Parti di kart CNC

Parti di motociclette CNC

Parti automobilistiche CNC

Cosa dicono i nostri clienti

Domande frequenti

Tutto quello che devi sapere prima di lavorare con HDC Manufacturing.

Come posso richiedere un preventivo?

Per richiedere un preventivo, è sufficiente condividere con noi i dettagli del progetto, inclusi disegni, requisiti dei materiali ed eventuali specifiche speciali. Il nostro team di ingegneri esaminerà le informazioni e fornirà un preventivo chiaro e dettagliato il più rapidamente possibile.

Quali sono i tempi di consegna tipici per gli ordini personalizzati?

I tempi di consegna variano a seconda della complessità del componente, della quantità e dei processi di produzione. Per la maggior parte dei progetti personalizzati, la produzione può essere completata entro poche settimane. I tempi di consegna stimati vengono confermati in fase di preventivo.

Quali sono le opzioni di spedizione disponibili?

Offriamo opzioni di spedizione flessibili, tra cui trasporto aereo, trasporto marittimo e consegna espressa. Sono disponibili spedizioni in tutto il mondo e le condizioni FOB possono essere concordate in base alle vostre esigenze.

In che modo HDC Manufacturing garantisce la qualità del prodotto?

La qualità è controllata in ogni fase della produzione. Dall'ispezione delle materie prime ai controlli in corso di lavorazione, fino all'ispezione finale, il nostro sistema di qualità è certificato ISO per garantire coerenza e affidabilità per ogni ordine.

Esiste una quantità minima d'ordine (MOQ)?

Il quantitativo minimo d'ordine dipende dal tipo di prodotto, dal materiale e dal processo di produzione. Supportiamo volumi di produzione flessibili e vi invitiamo a contattarci per discutere la soluzione più adatta al vostro progetto.

HDC Manufacturing può fornire assistenza nella progettazione o nella prototipazione?

Sì. Forniamo supporto ingegneristico e servizi di prototipazione per aiutarti a ottimizzare il tuo progetto in termini di producibilità, prestazioni e costi prima della produzione in serie.

Quali metodi di pagamento accettate?

Accettiamo metodi di pagamento sicuri, tra cui bonifici bancari, PayPal e altre opzioni comunemente utilizzate. Le condizioni di pagamento vengono confermate durante il processo di ordine per garantire chiarezza e trasparenza.

Fornite supporto agli importatori alle prime armi?

Sì. Collaboriamo regolarmente con gli importatori alle prime armi e forniamo assistenza su Incoterms, sdoganamento e opzioni di spedizione per garantire un processo di importazione senza intoppi.

Come posso contattare HDC Manufacturing per maggiori informazioni?

Potete contattarci tramite la nostra pagina contatti, via email o telefono. Il nostro team è pronto a discutere del vostro progetto e a rispondere a qualsiasi domanda.

Diamo vita al tuo progetto

Carica i tuoi disegni tecnici (STEP, IGES o PDF) per ricevere un feedback DFM (Design for Manufacturing) professionale e un preventivo competitivo entro 24 ore.

* Revisione tecnica disponibile. L'NDA può essere firmato su richiesta.